High-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and preparation method thereof

A technology of high temperature resistance and cable materials, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of rising product costs, expensive fluorine-based lubricants, etc., to promote flow, good hiding power, and good gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

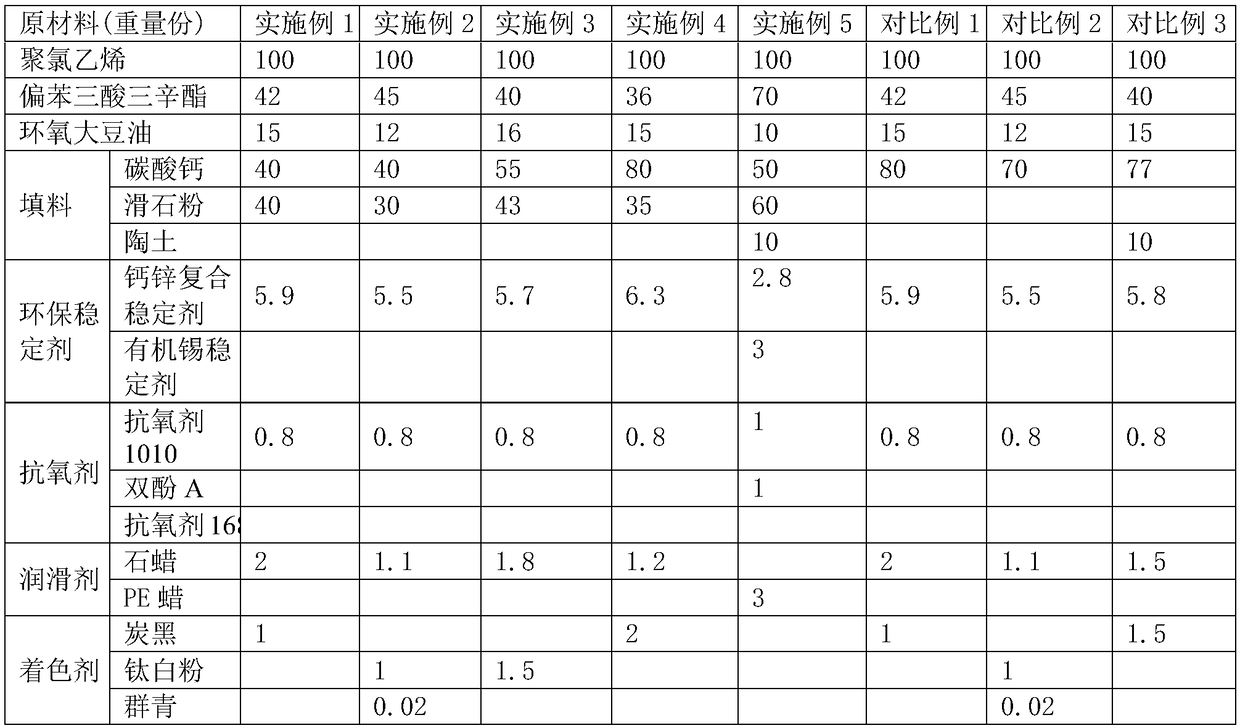

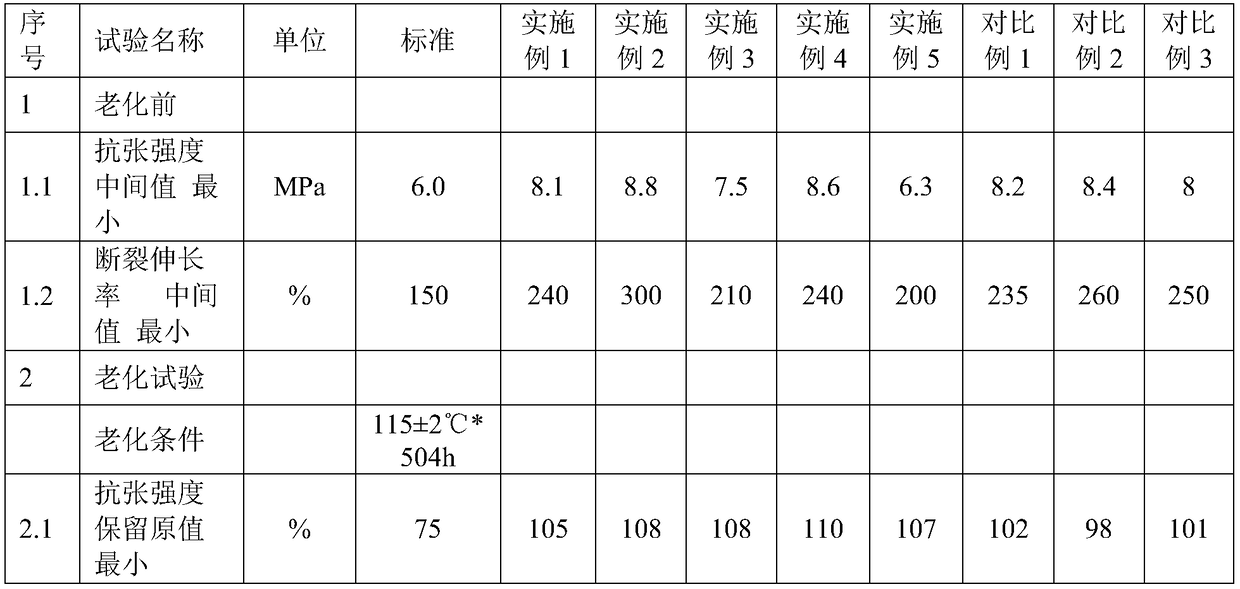

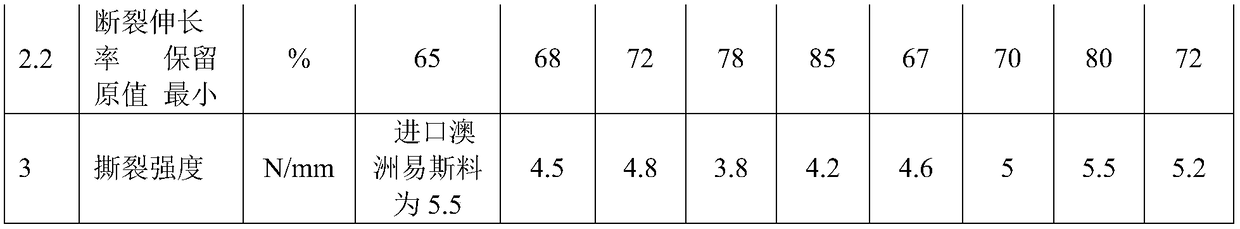

Examples

Embodiment 1

[0038] 1) take each component by the formula of embodiment 1 in table 1, for subsequent use;

[0039] 2) Take polyvinyl chloride resin and put it in a mixer, add trioctyl trimellitate and epoxidized soybean oil, stir until the polyvinyl chloride resin absorbs trioctyl trimellitate and epoxidized soybean oil, and then add environmental protection Stabilizer, after stirring evenly, add fillers, antioxidants, lubricants and colorants, stir evenly, when the temperature of the material rises to 110°C, unload the material into the cooling mixer to cool down, and discharge the material when the temperature drops to 45°C. get the mixture;

[0040] 3) The obtained mixture is sent to the SHJ type high-speed co-rotating twin-screw kneader (8 stages) in the double-stage extruder for mixing, and the processing temperature is set to 130-175°C (the temperature of the 1-3 stages is set 135°C, 4-5 section temperature is set to 165°C, 6-8 section temperature is set to 150°C), the feeding speed...

Embodiment 2

[0042] Carry out compounding and extruding granulation by the prescription of embodiment 2 in table 1, the technology of compounding and extruding granulation is the same as embodiment 1.

Embodiment 3

[0044] Carry out compounding and extruding granulation by the prescription of embodiment 3 in table 1, the technology of compounding and extruding granulation is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com