Cattlehide fiber production line and production method

A kraft fiber and production line technology, which is applied in the field of leather fiber, can solve problems such as poor quality and purity of kraft fiber, complex production line structure, and complicated production methods, so as to reduce labor intensity, increase automation, and improve quality and purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

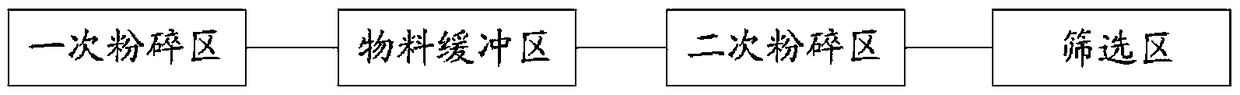

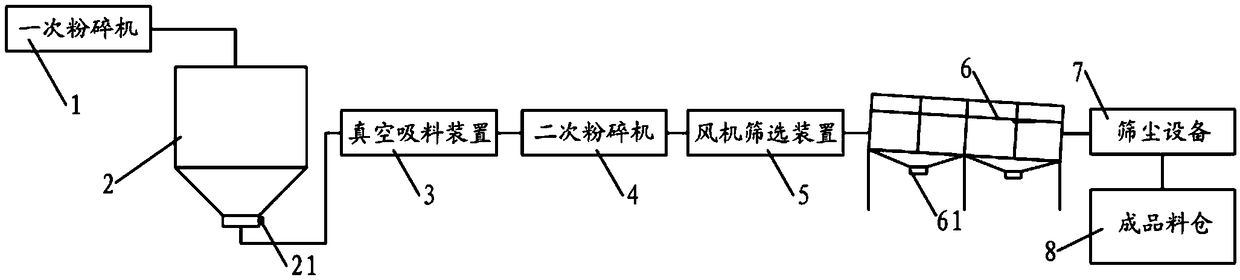

[0048] Present embodiment provides a kind of kraft fiber production line, as figure 1 and figure 2 As shown, the kraft fiber production line includes a primary crushing area, a material buffer zone, a secondary crushing area and a screening area arranged in sequence according to the production process, and a feeding pipe for transporting materials is provided between each area;

[0049] The primary crushing area includes a primary crushing machine 1, which is used for primary crushing of the leather material, and transports the primary crushed leather material to the material buffer zone through the delivery pipe ;

[0050] The material buffer zone includes a conical hopper 2 and a vacuum suction device 3, the feed port of the conical hopper 2 is connected to the delivery pipe, and the discharge port of the conical hopper 2 is connected to the vacuum suction device. connected to the feeding device 3, and the vacuum suction device 3 is used to suck the leather in the conical...

Embodiment 2

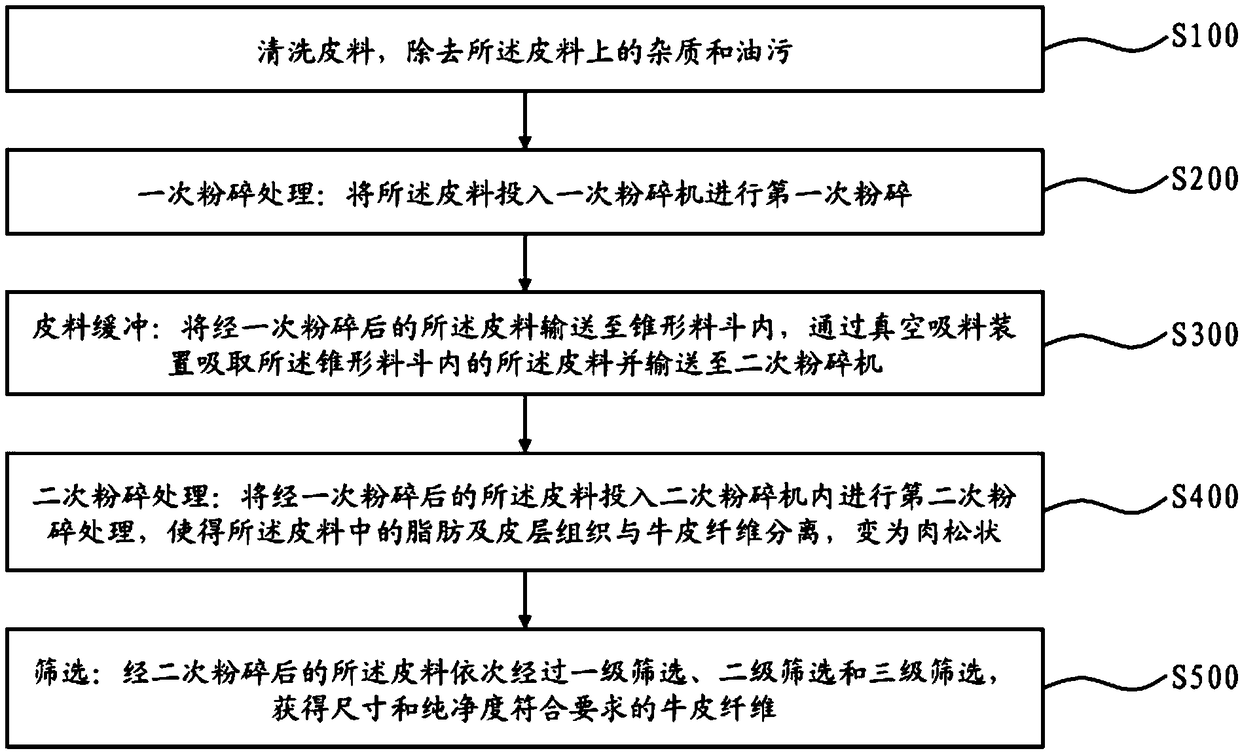

[0063] This embodiment provides a kind of production method of kraft fiber, this method adopts the kraft fiber production line in embodiment one to produce kraft fiber, and the production method flowchart is as follows image 3 As shown, its specific method includes the following steps:

[0064] S100: cleaning the leather to remove impurities and oil stains on the leather;

[0065] S200: primary pulverization treatment: put the leather material into primary pulverizer 1 for primary pulverization;

[0066] S300: leather material buffering: transport the leather material that has been pulverized once into the conical hopper 2, suck the leather material in the conical hopper 2 through the vacuum suction device 3 and transport it to the secondary pulverizer 4;

[0067] S400: secondary pulverization treatment: put the leather material after primary pulverization into the secondary pulverizer 4 for the second pulverization treatment, so that the fat and cortical tissue in the leat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com