Laminated wood plate forming method

A molding method and technology of wood boards, which are applied in the field of polymer wood material processing and molding, can solve the problems that it is not suitable to prepare large-size thick-walled polymer wood boards, and achieve the effects of meeting market needs, improving strength, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

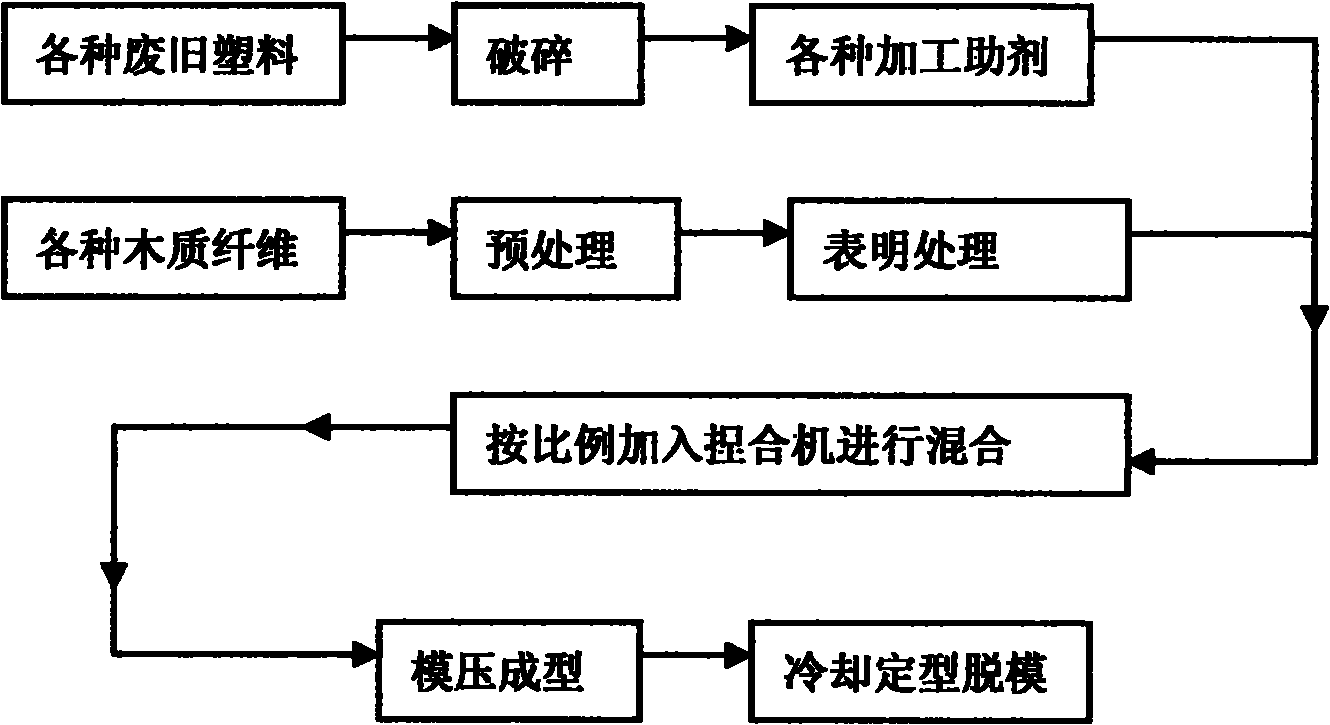

Method used

Image

Examples

Embodiment 1

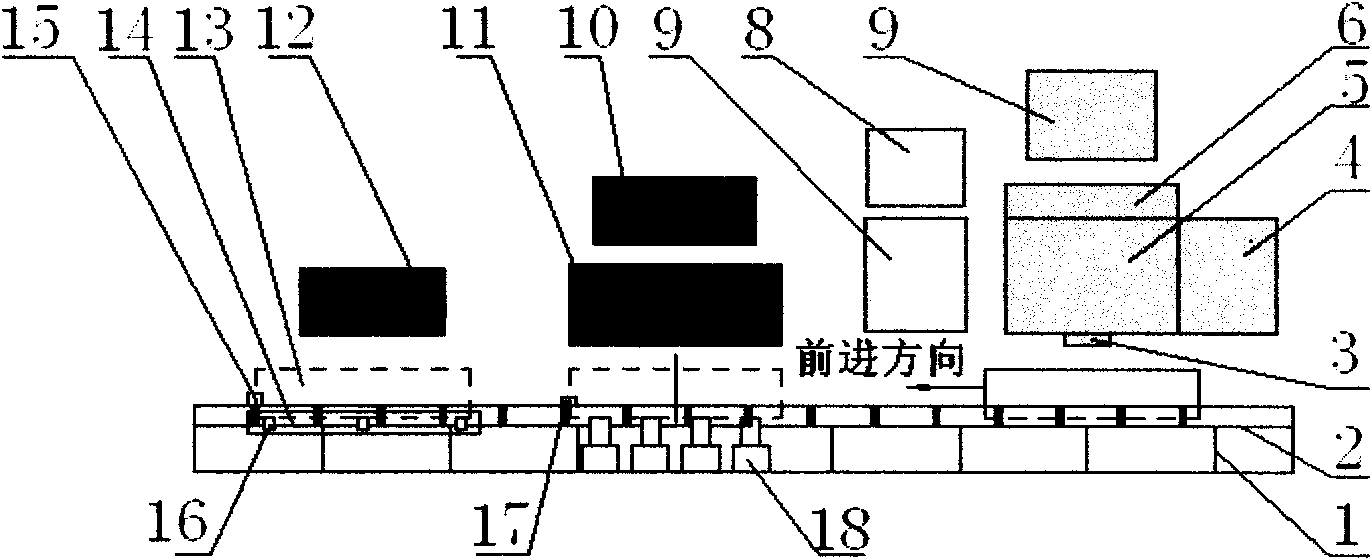

[0032] A kind of large-scale thick-walled polymer wood board production equipment of the present invention, its structure is as follows figure 1 As shown, the equipment includes a kneader 5, a track 2, a mold 13, a hydraulic press 11, and a demoulding mechanism 14 arranged in sequence along the conveying direction of the mould; the kneader 5 is controlled by a kneader electric control cabinet 7, and the kneader cylinder 9 is a Machine 5 provides a heat source. After the materials are mixed in kneader 5, they are sent to mold 13 on track 2 from outlet 3 below kneader 5. The track rollers drive mold 13 into hydraulic press 11, and hydraulic press 11 passes through the lower template 4 plunger oil cylinders 18 control its movement, and after the raw material is molded in the hydraulic press 11, the product is ejected by 6 ejection cylinders 16 of the demoulding mechanism 14 to realize demoulding.

[0033] The specification of the mold 13 of this embodiment is 4600mm×1300mm (lengt...

Embodiment 2

[0043] Molding equipment is the same as implementation example 1. The specification of the mold 13 in this embodiment is 4600mm×1300mm (length×width), and the thickness of the prepared polymer wood board is 150mm.

[0044] The material used in this implementation example is recycled waste polypropylene and polyethylene and polyvinyl chloride, crushed wood chips, ternary block copolymer polyethylene glycol-aliphatic polyester-polyamino acid, crosslinking agent N, N'- Methylene bisacrylamide, plasticizer polydibutyl adipate, reinforcing filler silicon whiskers.

[0045] First open the control cabinet 8 of the kneader oil cylinder and power on the kneader oil cylinder 9 to preheat the circulating oil to 220°C. In winter when the temperature is low, increase the preheating time appropriately so that the circulating oil can reach 220°C as much as possible. When the oil temperature is appropriate, turn on the kneading The machine top cover 6 puts the prepared waste plastics and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com