Method and device for treating acid gas

A treatment device and treatment method technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high energy consumption of amine liquid regeneration, complex production equipment, and the inability of production equipment to operate continuously for a long period, so as to reduce Energy consumption, environmental protection effect of treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

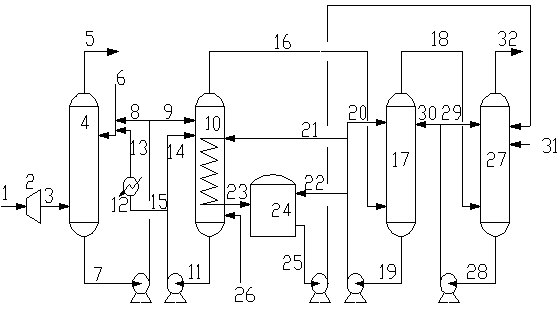

[0088] A refinery acid gas quantity Q=280Nm 3 / h, pressure 0.6Mpa, of which H 2 S volume fraction is 78%, CO 2 The volume fraction is 21%, and the remainder is hydrocarbons and other substances. use figure 1 The treatment method and device shown treat the acid gas. Wherein, the hydrate decomposer adopts a conventional tank structure with heat exchange equipment inside, and a stripping gas inlet line is provided on the shell of the hydrate decomposer.

[0089] The operating conditions and treatment effects during the treatment process are as follows: the hydrate working fluid consists of water, SDS accounting for 0.03% of the mass fraction of the aqueous solution, polyethylene glycol accounting for 8% of the mass fraction of the aqueous solution, diesel with a volume ratio of 1 / 2 to water, Composition of Span (sorbitan fatty acid ester) emulsifier with a mole ratio of 0.8% to water. The acid gas is pressurized by the compressor to 1.2Mpa and then introduced into the hydration re...

Embodiment 2

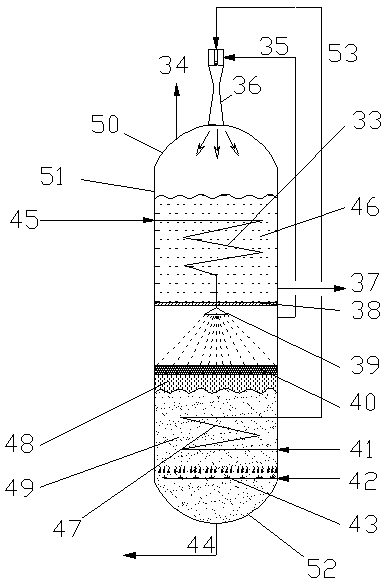

[0091] Same as Example 1, except that figure 2 In the structure of the decomposer, the volume ratio of the hydrate heating section and the hydrate dissociation and gasification section of the hydrate decomposer is 1 / 1, the liquid holding capacity in the hydrate heating section is 1 / 2 of the volume of the hydrate The liquid holding capacity of the decomposing and gasifying section is 1 / 2 of the total volume of this section. The broken baffle component in the hydrate decomposer adopts a screen structure with an average hole diameter of 5mm.

[0092] Due to the use of the present invention to provide a preferred hydrate decomposer, two-stage high-efficiency cascade heat exchange, the heat of the entire process is rationally used, and the working fluid can be decomposed (regenerated) under the same hydrate decomposing operating conditions as in Example 1. ) More complete, when the same effect as in Example 1, the amount of hydrate working fluid can be reduced to 4.6m 3 / h, reducing ...

Embodiment 3

[0094] Same as Example 2, except that the hydrate working fluid used is emulsified by water, SDS with a mass fraction of 0.03% of the aqueous solution and diesel with a volume ratio of 1 / 2 to water, and Span with a molar ratio of 0.8% to water. Agent composition.

[0095] Under the same operating conditions of the hydrate reactor as in Example 2, the CO in the tail gas treated by the hydration reactor 2 The concentration is about 70%; after the hydrate-rich working fluid is processed by the hydrate decomposer, CO in the gas 2 Concentration> 4%, increased CO 2 Form Na 2 CO 3 / NaHCO 3 The influence of other substances on the continuous and stable operation of the NaHS production unit has increased the difficulty of the long-term operation of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com