Pear syrup special for children and preparation method of pear syrup

A pear ointment and children's technology, which is applied in the field of children's special cough relieving pear ointment and its preparation, can solve the problems of food safety and commodity attributes, problems affecting product quality and health care effect, palatability and acceptability, and other problems, and achieves stability. Consistent quality and health benefits, easy-to-swallow, smooth-tasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The invention provides a kind of cough-relieving pear paste specially for children and its preparation method, comprising the following steps:

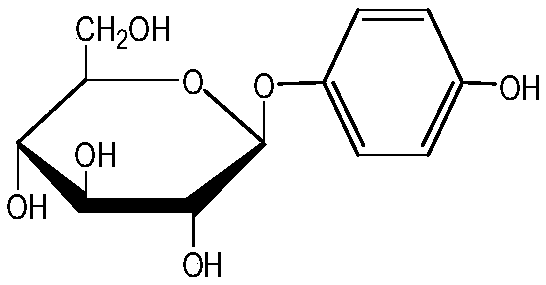

[0012] (a) First wash the pears, peel and remove the pits, squeeze and filter the pear pulp to obtain pear juice and pear residue; then beat the pear skin, pear core and pear residue, and extract with water to obtain extracted pears juice, (b) vacuum-concentrate squeezed pear juice and extracted pear juice to obtain concentrated pear juice, (c) use high-performance liquid chromatography to detect the content of arbutin in the two pear juices, and carry out according to product requirements Mixing, finally adding carrageenan, heating and mixing to make pear paste.

[0013] The present invention is not strictly limited to the species and varieties of the pears, including white pears, sand pears, Qiuzi pears, Xinjiang pears, and Western pears, and the preferred species are white pears and sand pears. Preferred varieties include: ...

Embodiment 1

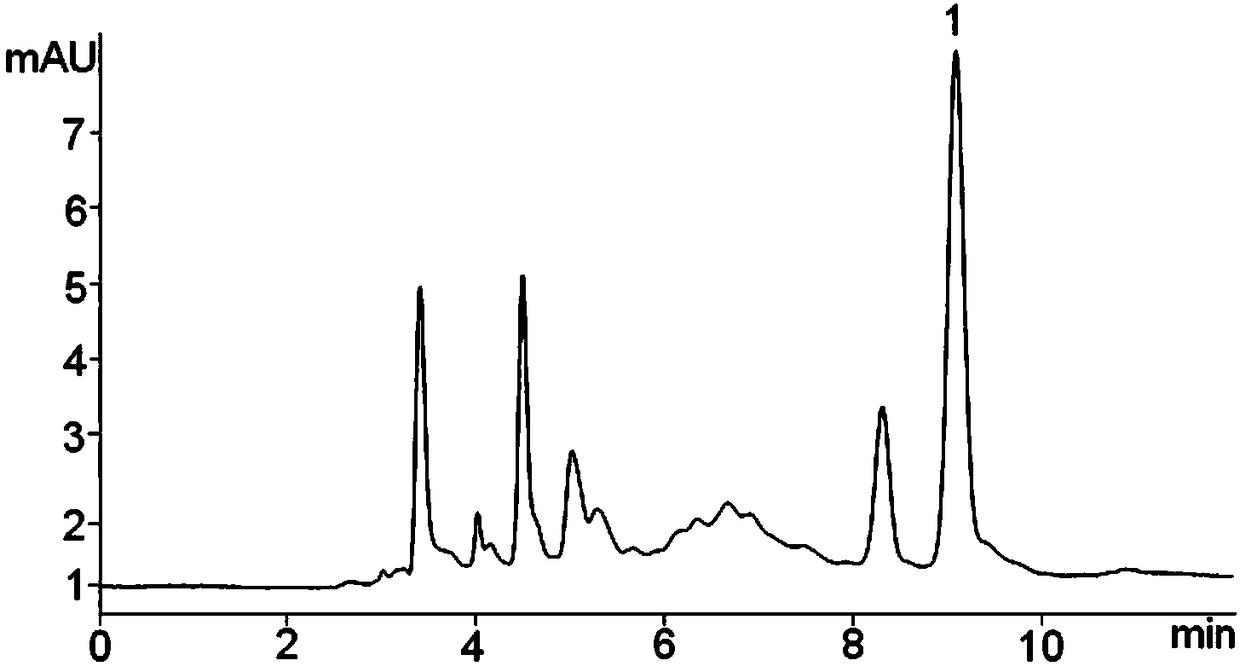

[0026] 300kg of duck pears are cleaned, peeled, and cored to obtain pear pulp, which is cut into pieces, placed in a juicer to squeeze the juice, and filtered with a bag centrifuge to obtain the filtrate; the filtrate is adopted by a vacuum thin film evaporator ( flash evaporation) to concentrate, the feed temperature of the pear juice is 80°C, the temperature of the evaporator is 110°C, the concentration time is less than 0.1min, and the temperature of the concentrated pear juice is 70°C. Make pulp concentrated pear juice 50kg, its soluble solids content is 50 ° of Brix. Use high performance liquid chromatography (HPLC) to measure the content of arbutin in pear juice according to the above-mentioned analytical conditions, wherein the content of arbutin is 400mg / kg, figure 2 It is the HPLC figure of arbutin in the concentrated pear juice that prepares. Then crush the collected pear skin, pear core, and pear dregs, add 3 times hot water for extraction, the temperature is 60°C...

Embodiment 2

[0028] Wash, peel and core 300kg of Chili pears to obtain pear pulp, cut the pear pulp into pieces, squeeze the juice in a juice extractor, and filter with a bag centrifuge to obtain the filtrate; filter the filtrate with a double-effect vacuum membrane The evaporator is concentrated, the first-effect heating temperature is 83-85°C, the second-effect heating temperature is 70-72°C, and the feed temperature of pear juice is 80°C. Prepare 50kg of concentrated juice with a concentration of 50-52°Brix. The content of arbutin in the pear juice was determined according to the above analysis conditions by high performance liquid chromatography, wherein the content of arbutin was 350mg / kg. Crush the collected pear skin, pear core, and pear dregs, add 2 times hot water to extract, the temperature is 70°C, the extraction time is 15min, centrifugal filtration, and the filtrate is vacuum concentrated in the same way to obtain a concentration of 52°Brix Concentrated juice 10kg, the conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com