Titanium alloy blisk side milling cutting parameter optimization method for multiple targets

A cutting parameter, integral blisk technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of low processing efficiency and large surface roughness, and achieve high processing efficiency and small workpiece surface roughness. , the effect of improving correctness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

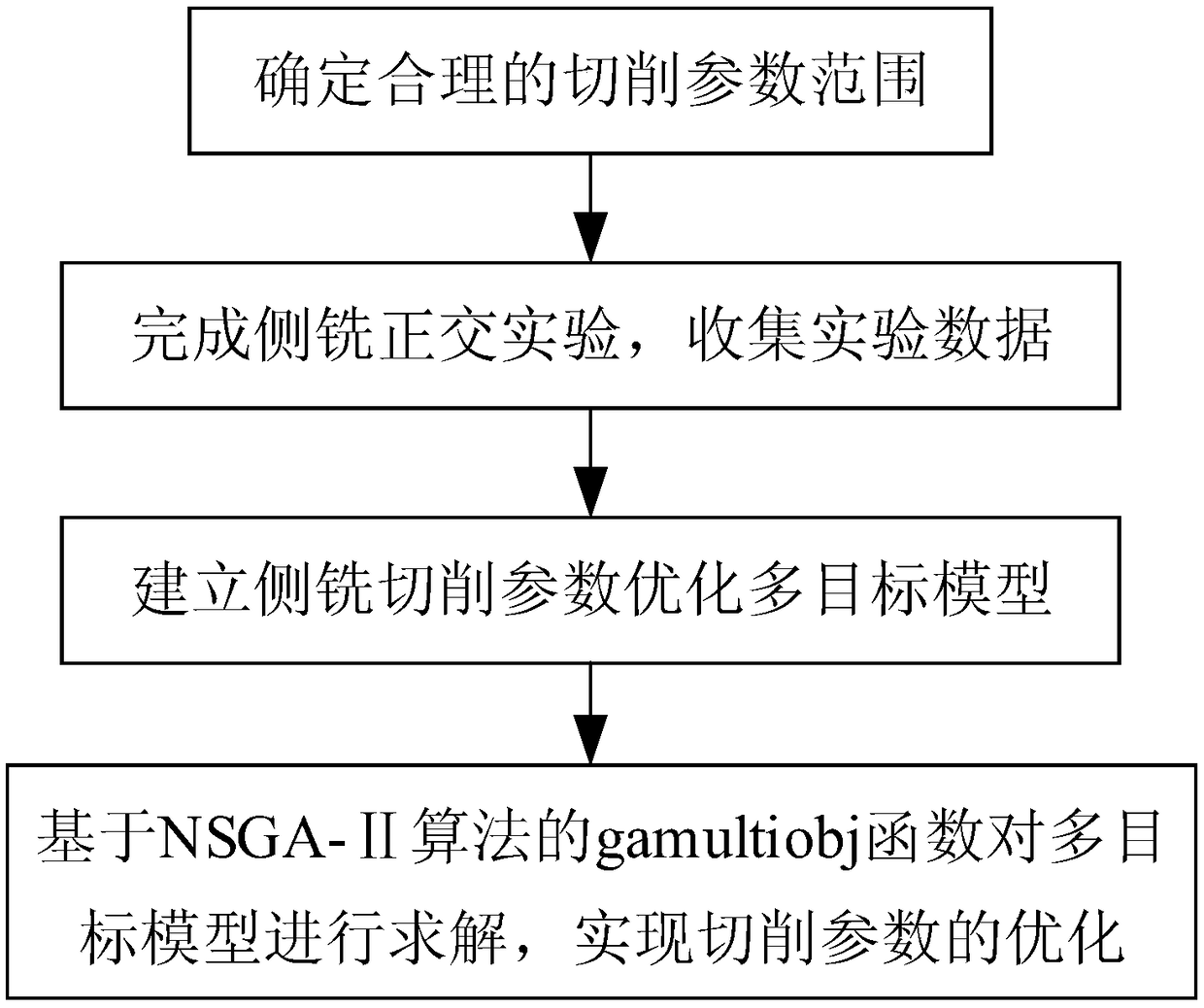

[0030] Specific implementation manner one: such as figure 2 As shown, this embodiment discloses a multi-objective optimizing method for cutting parameters of titanium alloy blisk side milling, and the method steps are as follows:

[0031] Step 1: Determine the reasonable range of cutting parameters;

[0032] The cutting parameter range satisfies the following relationship:

[0033]

[0034] Among them, the cutting parameters include cutting speed v c , Feed per tooth f z , Radial depth of cut a e , Axial depth of cut a p , The unit is m / min, mm / z, mm, mm;

[0035] Step 2: Complete the side milling orthogonal experiment and collect experimental data;

[0036] The specific cutting parameters of the side milling orthogonal experiment satisfy the following relationship:

[0037]

[0038] Step 3: Establish a multi-objective model for side milling cutting parameters optimization;

[0039] The cutting parameter optimization multi-objective model includes a cutting force model, a surface roughn...

specific Embodiment approach 2

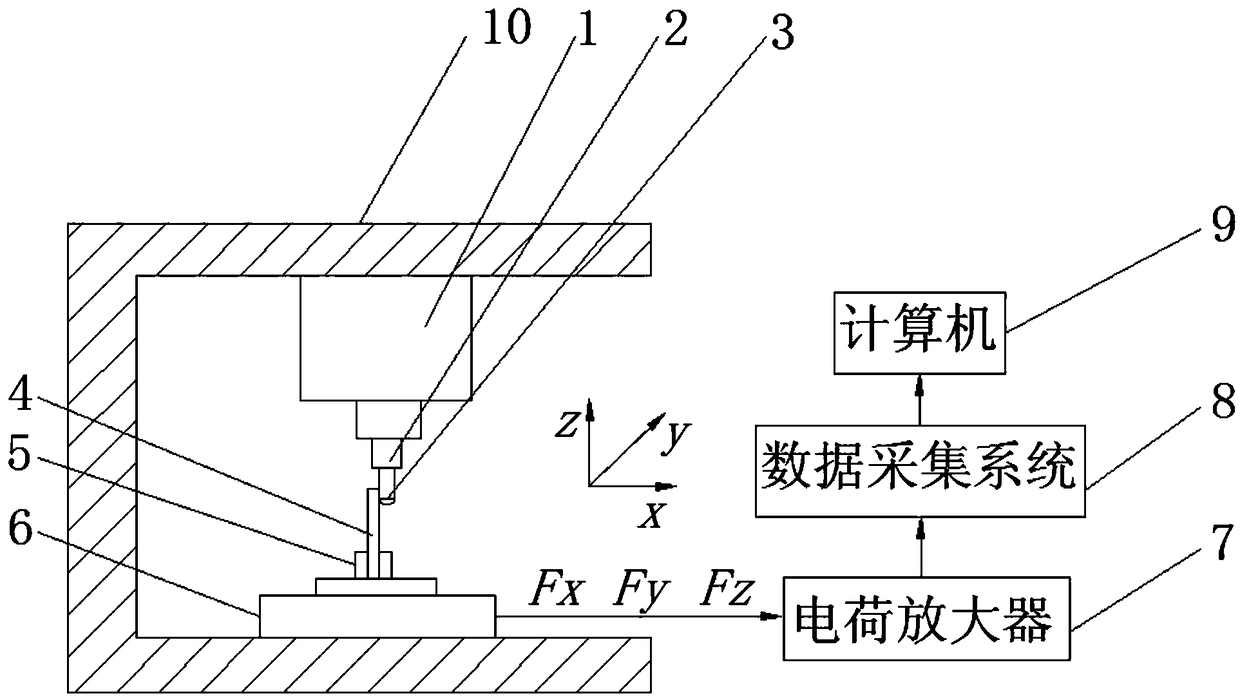

[0050] Specific implementation manner two: such as figure 1 As shown, this embodiment is a further description of specific embodiment 1. In step 2, the specific method of the side milling orthogonal experiment is:

[0051] The machine tool 10 adopts a (VDL-1000E) vertical machining center, and the tool adopts a cemented carbide ball-end milling cutter 3 with a diameter of 8mm. The cemented carbide ball-end milling cutter 3 is installed on the tool holder 2, and then the The tool holder 2 is installed on the spindle 1 of the machine tool 10. The material of the workpiece 4 is TC4, the length of the workpiece 4 is 80×80×3mm, and the workpiece 4 is clamped on the (Kistler9257B) dynamometer 6 by the fixture 5 , And install and fix the dynamometer 6 on the machine tool 10, the cutting force test data F x , F y And F z It is amplified by the charge amplifier 7 and input to the computer 9 through the data acquisition system 8, and the surface roughness is measured by the (TR200) rough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com