Forced frequency ignition system for internal combustion engines

An ignition system and internal combustion engine technology, applied in the field of ignition coils and fuel electric ignition devices, can solve the problems of small size, complex electronics, and low quality, and achieve the effects of preventing radio frequency interference, reducing erosion, and easy radio frequency shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

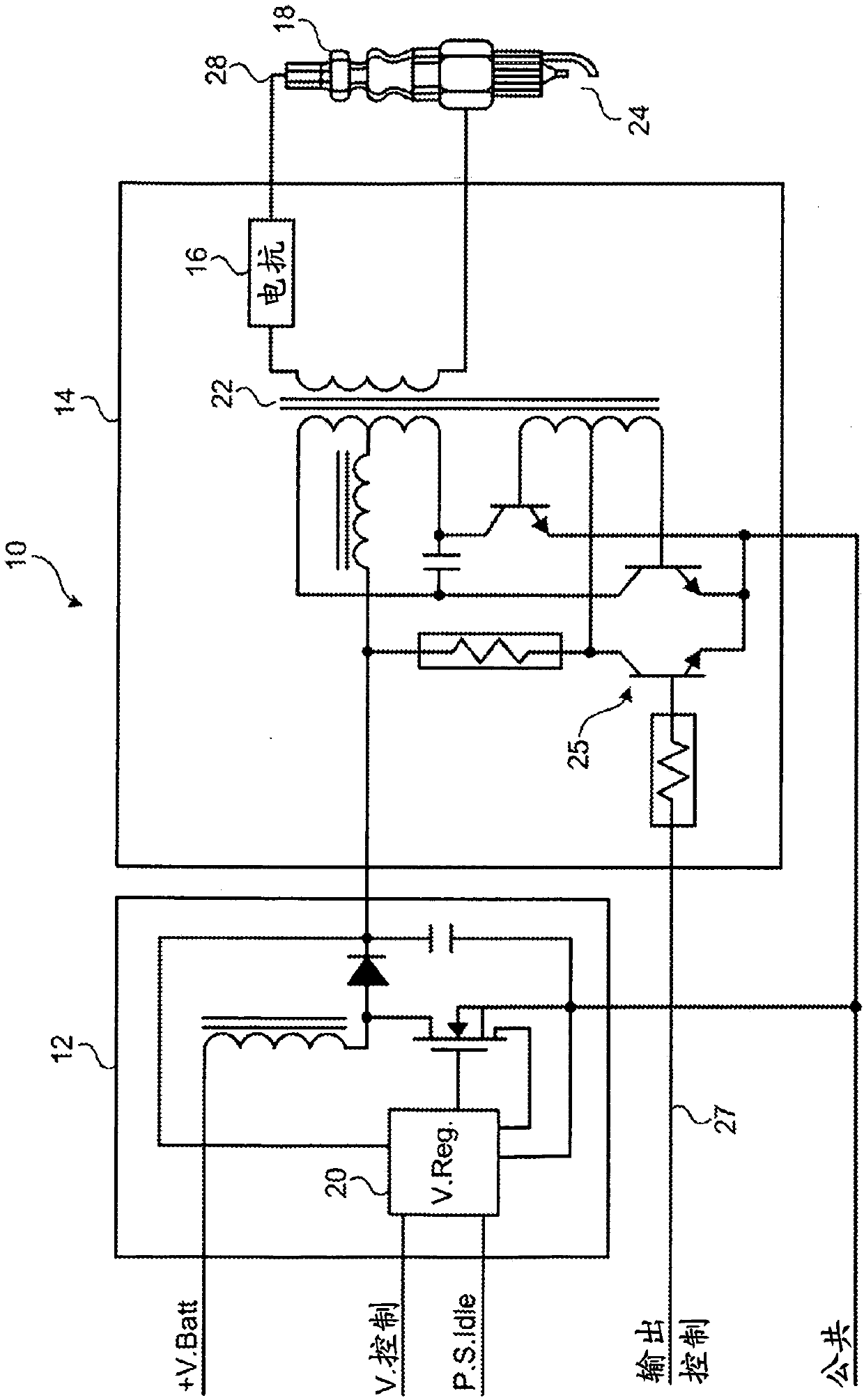

[0040] refer to figure 1 , which shows an ignition system 10 according to a preferred embodiment of the present invention. Ignition system 10 includes a pair of functional groups. The first functional group 12 is a power boost voltage regulator circuit. The second functional group 14 is the output section. The second functional group 14 produces a high voltage DC output which is current limited by the ballast reactance 16 . Functional groups 12 and 14 cooperate to properly ignite spark plug 18 . Functional group 12 is an input power boost voltage regulator. Functional group 12 provides feedback controlled regulated DC power to a second functional group 14 to allow the invention to be deployed in engine systems with varying input DC power voltages without adjustment. The input power boost voltage regulator 12 may additionally incorporate suitable means when appropriate to reduce the output voltage and enter an idle mode to reduce the overall module current drawn from the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com