A plasma processing device

A processing device and plasma technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as space congestion of the lower electrode, easy change of distance, influence of electric field distribution, etc., and achieve simple structure setting, space saving, and component setting reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

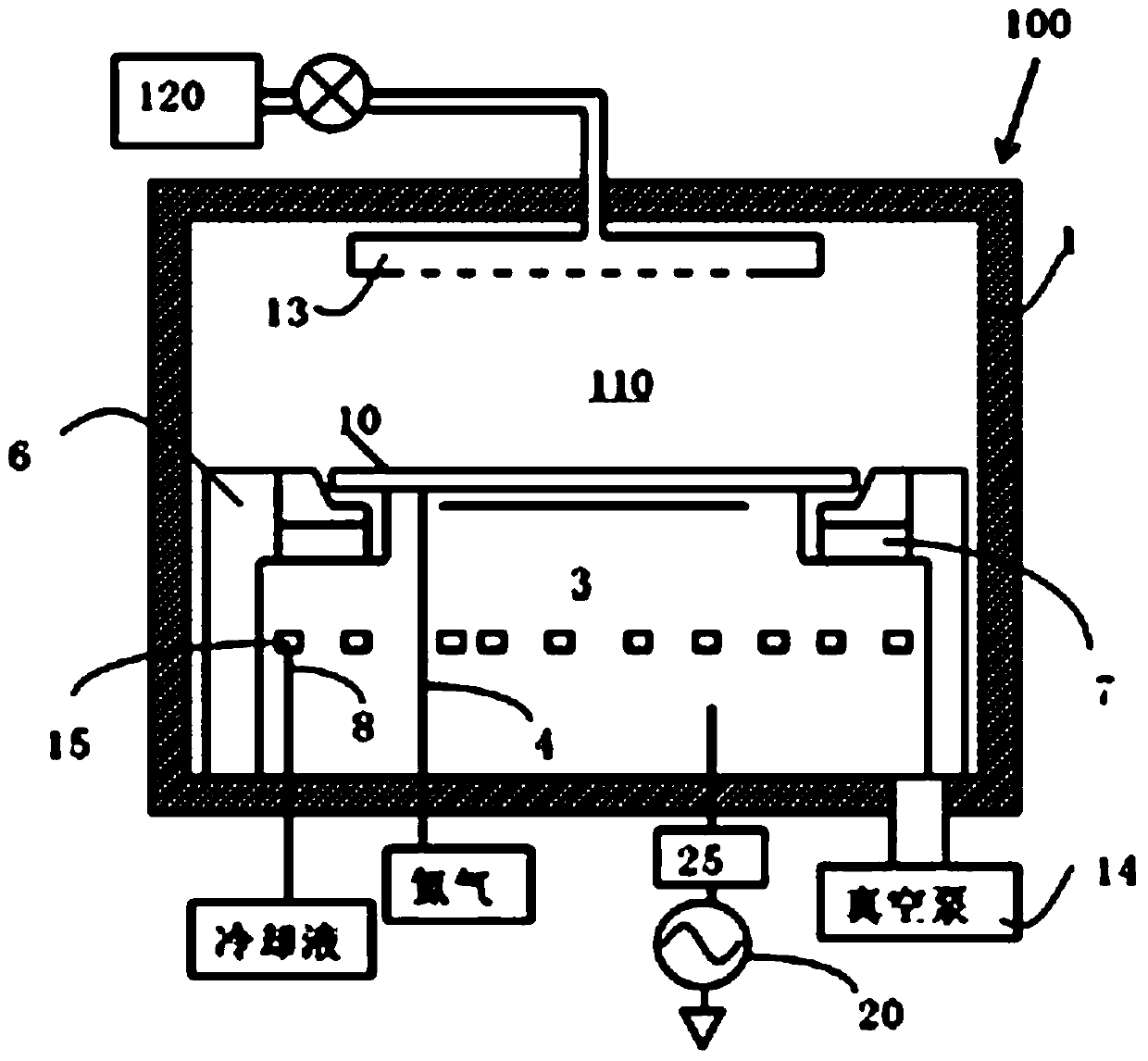

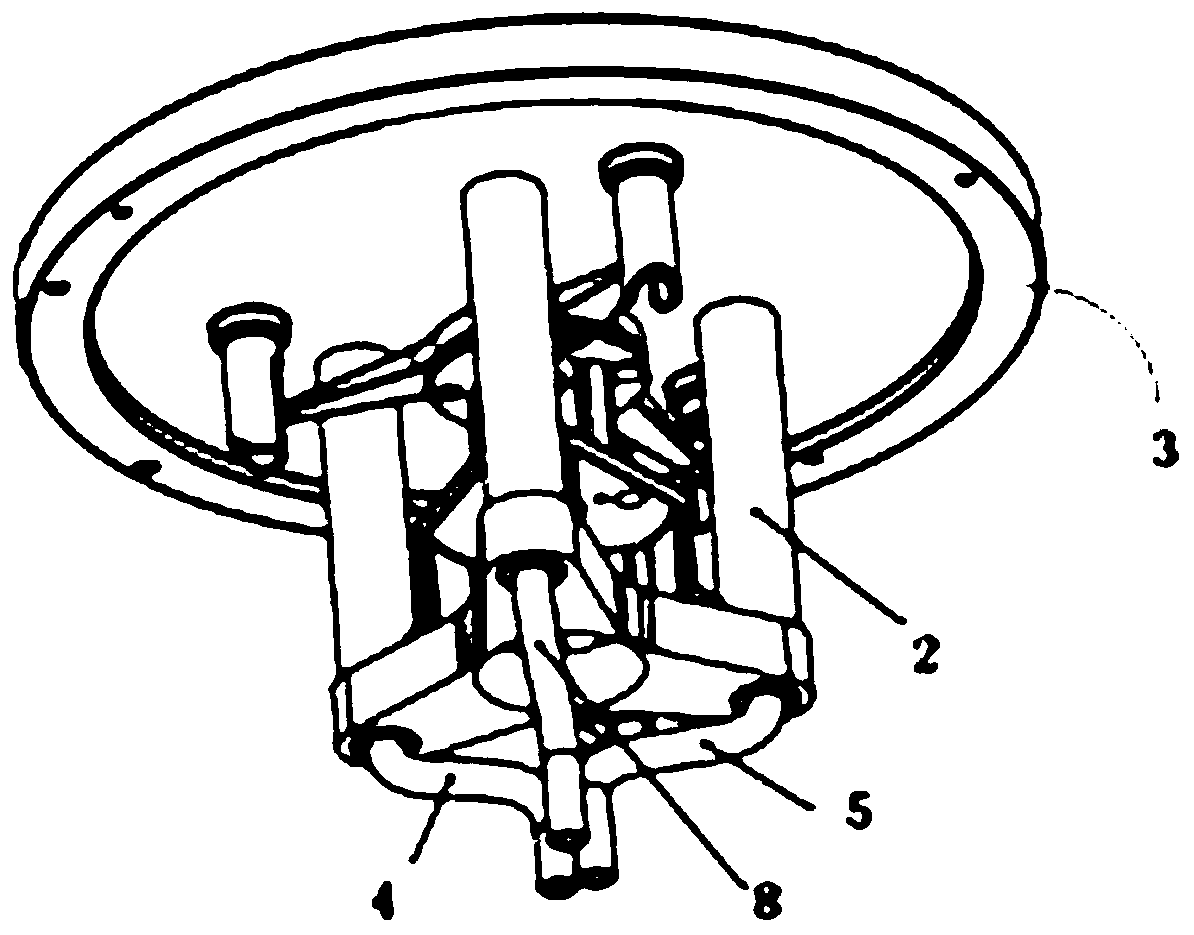

[0018] figure 1 It shows a schematic structural view of a plasma processing device according to the present invention, the plasma processing device 100 includes a vacuumable reaction chamber 110 surrounded by an outer wall 1, and a bottom of the reaction chamber is provided near the bottom of the reaction chamber for supporting the The lower electrode 3 of the substrate 10 is surrounded by an isolation ring 7 and a grounding ring 6 arranged around the isolation ring 7 . The upper electrode 13 is arranged near the top of the reaction chamber corresponding to the lower electrode 3, and the side of the upper electrode 13 facing away from the lower electrode 3 is connected to the reaction gas source 120. The upper electrode 13 is provided with a small hole that allows the reaction gas to pass through, and simultaneously serves as the reaction gas source. The reaction gas in 120 is delivered to the gas shower head in the reaction chamber 110 . A vacuum pump 14 is arranged below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com