Aqueous coating material composition and coating film forming method

A technology of water-based coatings and compositions, which is applied in the direction of polyester coatings, polyurea/polyurethane coatings, coatings, etc., and can solve the problems of not being able to obtain sufficient cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

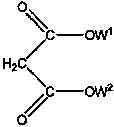

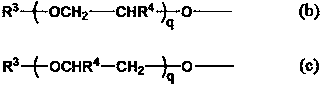

[0085] In the preparation of the above-mentioned (A) water-based resin, when carrying out emulsion polymerization in an aqueous medium, for example, in water or an aqueous medium containing an organic solvent such as alcohol as needed, the emulsifier is dissolved, and the emulsifier is dripped under heating and stirring. Addition of a substance mixed with an α,β-ethylenically unsaturated monomer and a polymerization initiator used as raw materials is carried out thereby. The α,β-ethylenically unsaturated monomer-mixed substance used as a raw material can be emulsified in advance using an emulsifier and water.

[0086] As a polymerization initiator that can be suitably used for emulsion polymerization, azo-based oily compounds (such as azobisisobutyronitrile, 2,2'-azobis(2-methylbutyronitrile) and 2, 2'-azobis(2,4-dimethylvaleronitrile), etc.), and aqueous compounds (such as anionic 4,4'-azobis(4-cyanovaleric acid), 2,2- Azobis (N-(2-carboxyethyl)-2-methylpropionamidine and ca...

manufacture example 1

[0265] Production Example 1 Production of acrylic emulsion having hydroxyl and carboxyl groups

[0266] 1,000 parts of deionized water was poured into a reaction container equipped with a stirrer, a nitrogen introduction pipe, a temperature control device, a condenser, and a dropping funnel, and the temperature was raised to 80° C. while stirring under a nitrogen atmosphere.

[0267] 103 parts of styrene, 290 parts of n-butyl methacrylate, 280 parts of n-butyl acrylate, 302 parts of hydroxyethyl acrylate, 26 parts of acrylic acid, 3 parts of dodecyl mercaptan and Latemur PD-104 as an emulsifier (manufactured by Kao Corporation, 20% aqueous solution) was added to 1,000 parts of deionized water and emulsified to obtain a pre-emulsion, and the resulting pre-emulsion was mixed with an aqueous initiator solution obtained by dissolving 3 parts of ammonium persulfate in 300 parts of deionized water Add dropwise over 2 hours together.

[0268] After completion of the dropwise addit...

manufacture example 2

[0269] Production Example 2 Production of acrylic emulsion having hydroxyl and carboxyl groups

[0270] The amount of monomers in the monomer mixture of Production Example 1 was changed to 90 parts of styrene, 249 parts of n-butyl acrylate, 403 parts of n-butyl methacrylate, 232 parts of hydroxyethyl acrylate, 26 parts of acrylic acid, ten parts Except for 3 parts of dialkyl mercaptan, after polymerization in the same manner, 8.2 parts of N,N-dimethylaminoethanol was added to obtain an acrylic emulsion having a resin solid content of 30% by mass. The acrylic emulsion calculated from the monomer composition had a hydroxyl value of 100 mgKOH / g and an acid value of 20 mgKOH / g in terms of resin solid content. In addition, the number average molecular weight measured by GPC after water removal of the acrylic resin in the obtained acrylic emulsion was 43,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com