A kind of mineral soft capsule and preparation method thereof

A technology of soft capsules and minerals, applied in the field of medicine, can solve problems such as poor suspending effect of beeswax, uneven product components, and consumers' unsuitability to the taste of vegetable oil, etc., to achieve increased acidity and flavor, good pH adjustment performance, and deterrence The effect of corruption product generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

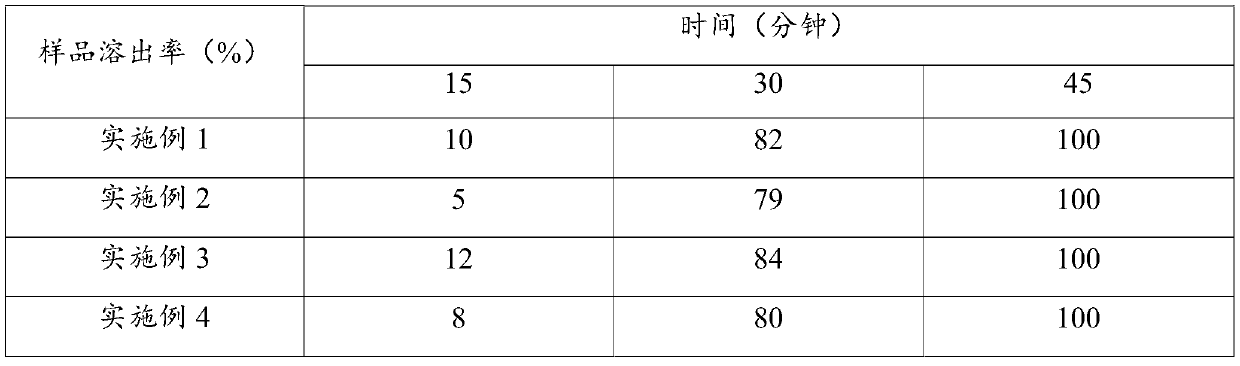

Examples

Embodiment 1

[0038] 1. Mineral soft capsules: composed of soft capsule contents and soft capsule shell;

[0039] 1. The contents of the soft capsule include mineral active ingredients and pharmaceutical adjuvants. In parts by weight, the mineral active ingredients are ferrous gluconate and zinc gluconate, and the ferrous gluconate is 5.5 parts, gluconic acid Zinc is 4 parts;

[0040] Described pharmaceutical excipient comprises diluent, suspending agent and additive, and described diluent is 60 parts of glycerin, 0.5 part of sorbitol liquid and 6 parts of maltitol; Described suspending agent is 3 parts of mono- and diglyceride fatty acids ester; the additives include sour agent: 0.5 parts of sodium citrate and 0.5 parts of citric acid; oligosaccharides: 3 parts of stachyose and 2 parts of fructose; 3 parts of soybean lecithin; 0.5 part of fruity essence.

[0041] 2. Soft capsule shell: 10 parts of gelatin, 4 parts of glycerin, and 10 parts of purified water.

[0042] Two, the preparation...

Embodiment 2

[0047] 1. Mineral soft capsules: composed of soft capsule contents and soft capsule shell;

[0048] 1. The contents of the soft capsule include mineral active ingredients and pharmaceutical adjuvants. In parts by weight, the mineral active ingredients are ferrous gluconate and zinc gluconate, and the ferrous gluconate is 4 parts, gluconate Zinc is 2.5 parts;

[0049] Described pharmaceutical excipient comprises diluent, suspending agent and additive, and described diluent is 30 parts of glycerin, 1 part of sorbitol liquid and 1.5 parts of maltitol; Described suspending agent is 1.3 parts of mono- and diglycerin fatty acids ester; the additives include sour agent: 1 part of sodium citrate and 1 part of citric acid; oligosaccharides: 5 parts of stachyose and 4.5 parts of fructose; 1 part of soybean lecithin; 0.5 part of fruity essence.

[0050] 2. Soft capsule shell: 10 parts of gelatin, 3 parts of glycerin, and 10 parts of purified water.

[0051] Two, the preparation method ...

Embodiment 3

[0056] 1. Mineral soft capsules: composed of soft capsule contents and soft capsule shell;

[0057] 1. The contents of soft capsules include mineral active ingredients and pharmaceutical excipients, calculated in parts by weight,

[0058] Described mineral active ingredient is ferrous gluconate and zinc gluconate, and described ferrous gluconate is 7 parts, and zinc gluconate is 5.5 parts;

[0059] Described pharmaceutical excipient comprises diluent, suspending agent and additive, and described diluent is 70 parts of glycerin, 5 parts of sorbitol liquids and 12.5 parts of maltitol; ester; the additives include sour agent: 0.1 part of sodium citrate and 0.1 part of citric acid; oligosaccharides: 5 parts of stachyose and 5 parts of fructose; 2.3 parts of soybean lecithin.

[0060] 2. Soft capsule shell: 10 parts of gelatin, 5 parts of glycerin, and 10 parts of purified water.

[0061] Two, the preparation method of described mineral soft capsule comprises the steps:

[0062]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com