Processing method of Artemisia selengensis silage

A technology of silage and processing method, which is applied in the preservation method of animal feed raw materials, feed, animal feed, etc., can solve the problems of poor effect, high incidence of diseases and insect pests, and cannot be made into silage, so as to avoid poor sealing. phenomenon, improve the effect of anaerobic fermentation, improve the effect of feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

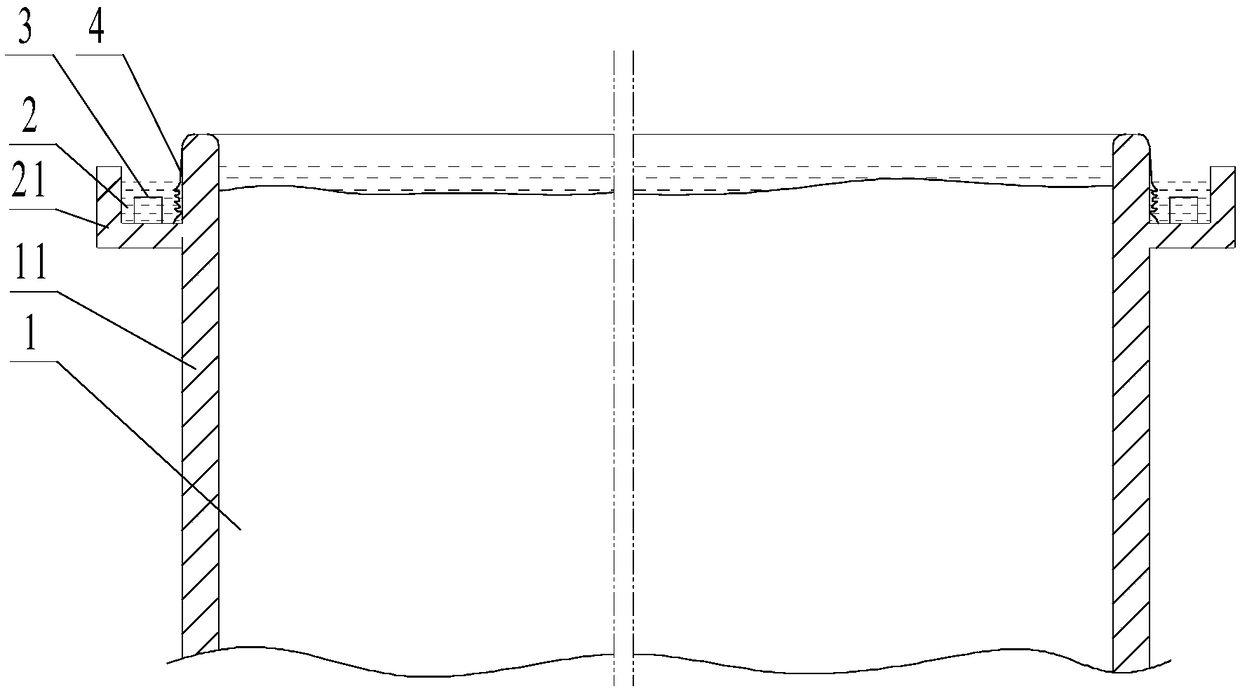

[0019] A kind of processing method of Artemisia quinoa silage, the raw material that percentage by weight is 75% of Artemisia quinoa leaves, 15% of eucalyptus leaves, 0.1% of salt and 0.1% of mold-removing fungus is mixed evenly, the moisture is controlled to be 60%, and sealed layer by layer In the water-sealed type fermenter tank and compacted, the temperature in the control container is 15 ℃ for anaerobic fermentation, and the silage is produced after 20 days of fermentation. The content of crude protein in the dry silage product prepared by this method is 21.2%.

Embodiment 2

[0021] A kind of processing method of Artemisia quinoa silage, the raw material that percentage by weight is 80% of Artemisia quinoa root, 18% of eucalyptus leaves, 0.3% of salt and 0.2% of mold-removing fungus is evenly mixed, the moisture content is controlled to be 65%, and the airtight In the water-sealed type fermenter tank and compacted, the temperature in the control container is 25 ℃ for anaerobic fermentation, and the silage is produced after 18 days of fermentation. The content of crude protein in the dry silage product prepared by the method is 23.5%.

Embodiment 3

[0023] A kind of processing method of Artemisia quinoa silage, the raw material that percentage by weight is 85% of Artemisia quinoa stem, 20% of eucalyptus leaves, 0.5% of salt and 0.3% of mold-removing fungus is evenly mixed, the moisture content is controlled to be 70%, and sealed layer by layer In the water-sealed fermenter of the same and compacted, the temperature in the control container is 35 ℃ for anaerobic fermentation, and the silage is produced after 15 days of fermentation. The content of crude protein in the dry silage product prepared by this method is 26.1%.

[0024] The above three implementations were carried out with discarded leaves, roots and old stems from the leftovers of Artemisia quinoa, and the raw materials were all put into a water-sealed fermentation tank for fermentation. Due to the sealing of the water, a good anaerobic environment was created, so that the The effect of anaerobic fermentation improves the quality of silage. The silage made by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com