Concave and convex glass curtain wall structure and construction method for same

A glass curtain wall and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of increasing material and labor costs, prone to water leakage at joint positions, and delaying the construction period, so as to avoid the phenomenon of lax sealing, The effect of saving labor costs and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

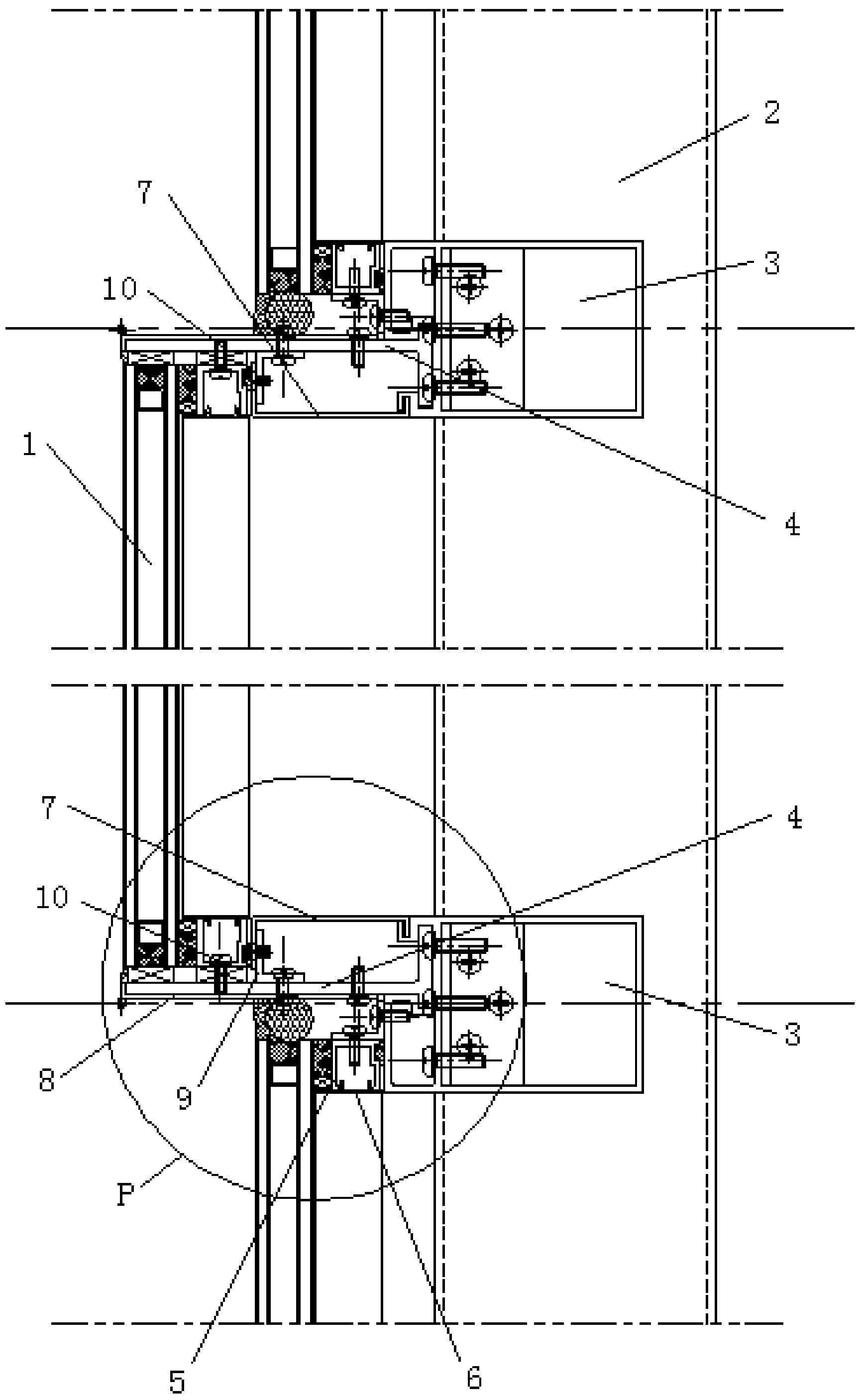

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

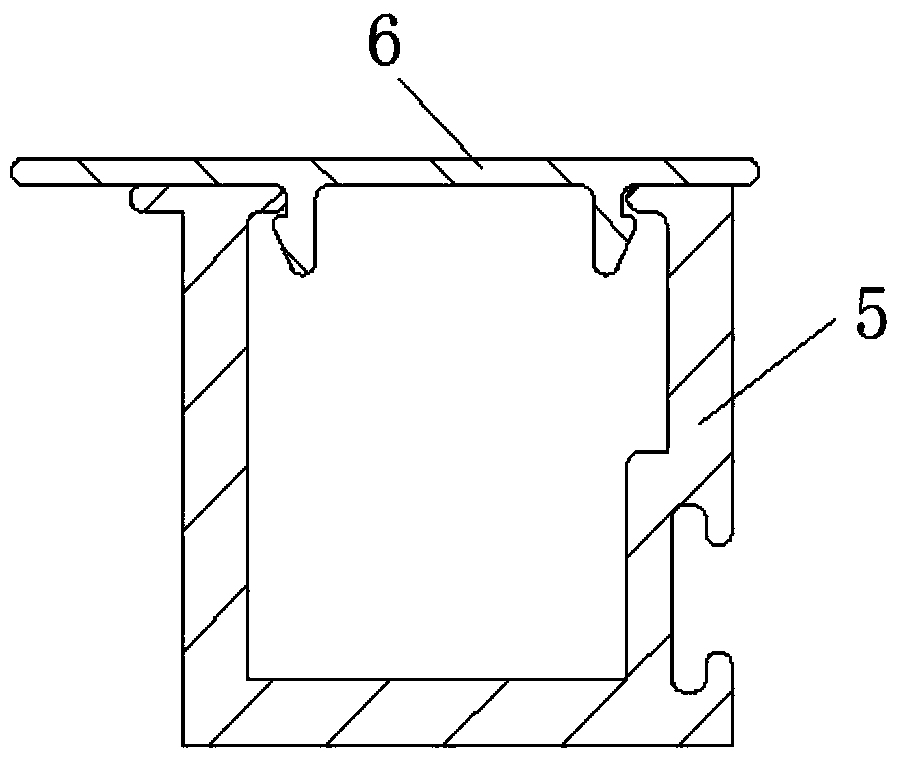

[0026] Such as figure 1 As shown, the concave-convex glass curtain wall structure described in this embodiment includes a skeleton and curtain wall glass 1 installed on the skeleton. The skeleton is a frame structure, which is formed by overlapping columns 2 and beams 3. There is a supporting plate 4, the curtain wall glass 1 is provided with a sub-frame 5, and the curtain wall glass 1 is installed on the beam 3 or the supporting plate 4 through the sub-frame 5.

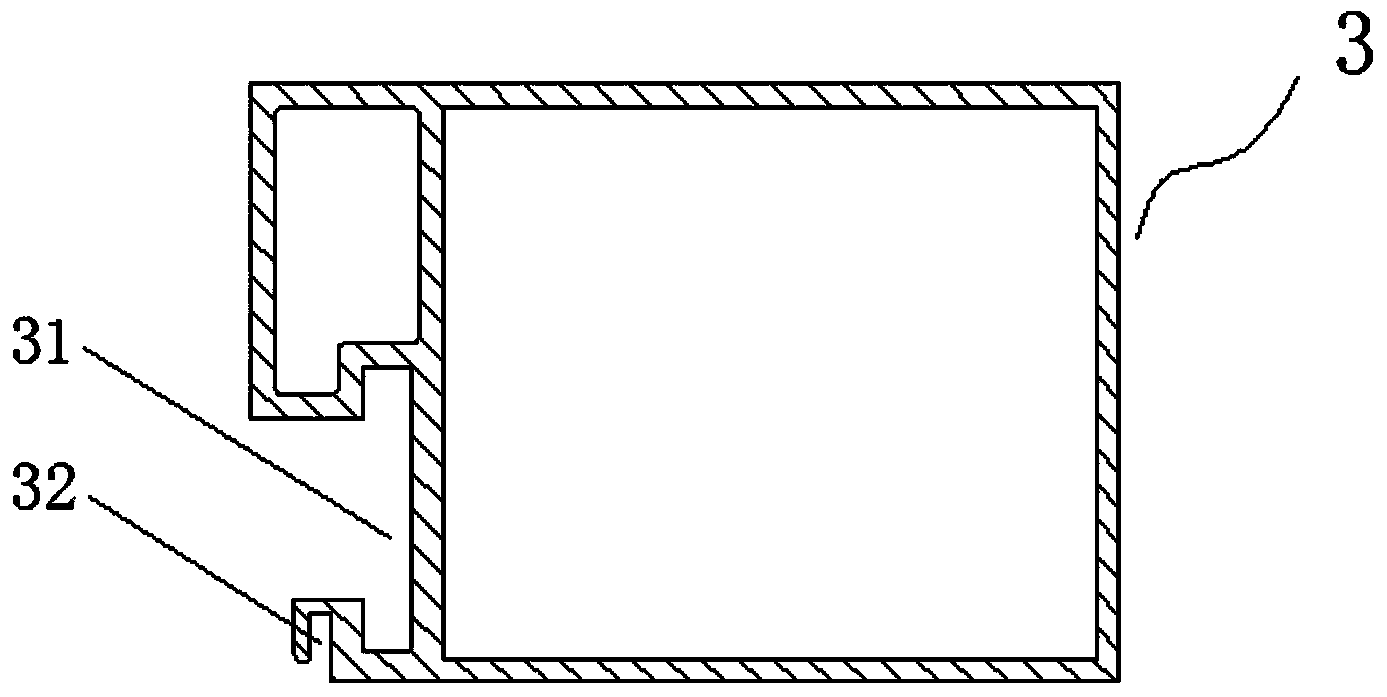

[0027] In this solution, the curtain wall glass 1 is arranged in a concave-convex form through the staggered position formed by the support plate 4 and the beam 3, that is, the concave curtain wall glass 1 is fixed on the beam 3, and the protruding curtain wall glass 1 is fixed on the support plate 4; Said beam 3 is a closed profile, such as figure 2 As shown, the supporting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com