Production process of beverage packaging box and edge bonding machine thereof

A production process and packaging box technology, which is applied to the production process of beverage packaging boxes and the field of edge sealing machines, can solve the problems of easy liquid leakage, easy overflow of glue, poor edge sealing effect, etc., so as to avoid poor sealing, Accurately control the amount of glue applied and avoid the effect of glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

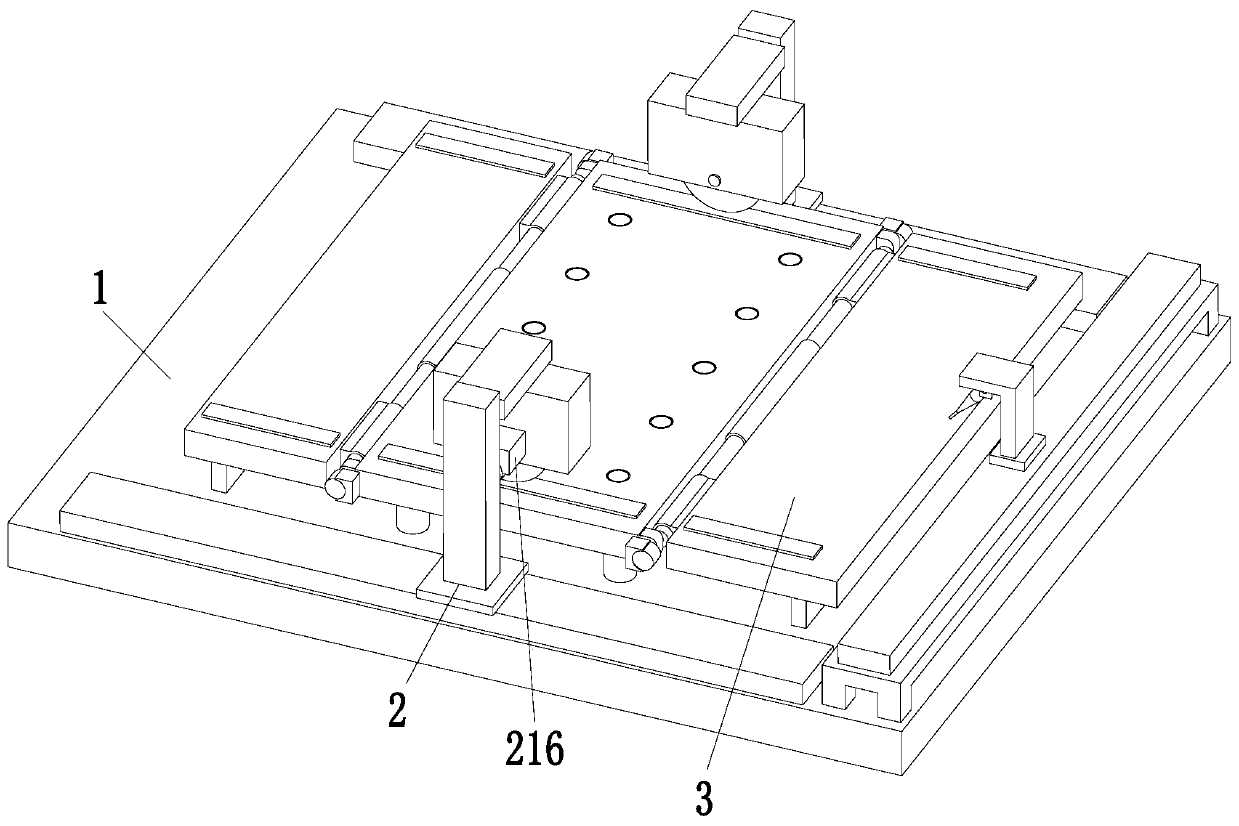

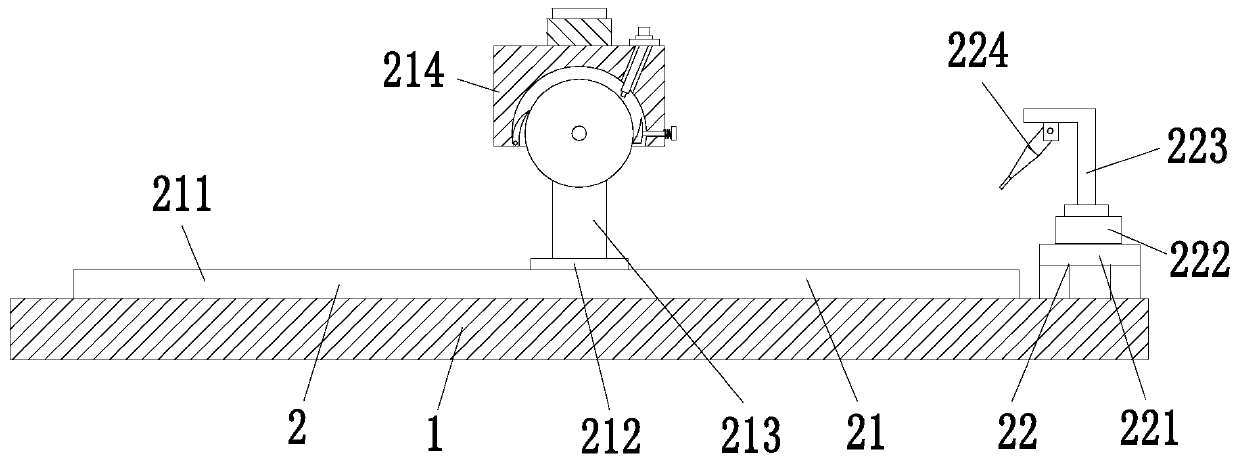

[0038] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

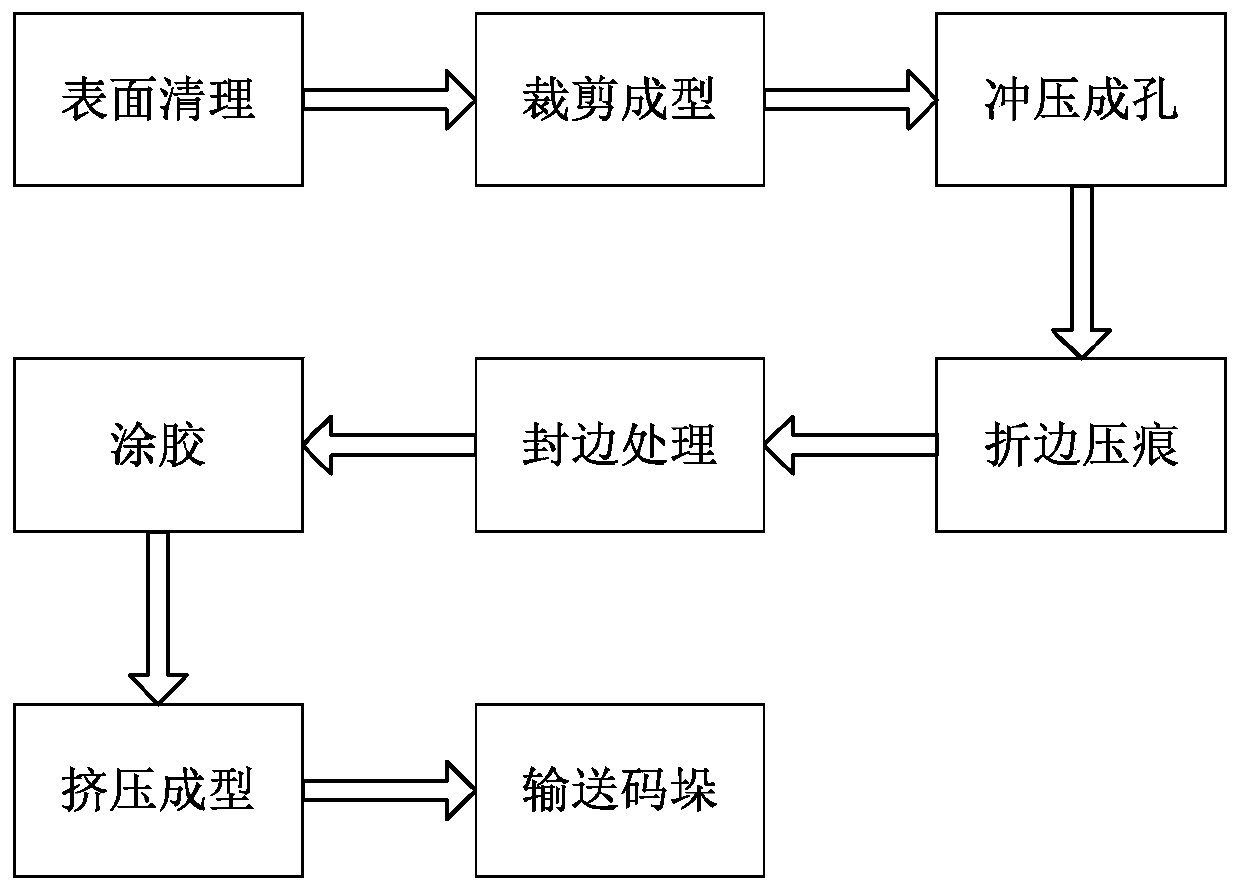

[0039] like Figure 1 to Figure 5 As shown, a production process of a beverage packaging box includes the following steps:

[0040] S1. Surface cleaning: remove the bacteria, dust and other impurities remaining on the inner surface of the wrapping paper by high-temperature disinfection;

[0041] S2, cutting and forming: according to the size of the packaged beverage box, the packaging paper in step S1 is cut as required by the cutting machine, and the optional model of the cutting machine is JX149003;

[0042] S3, punching into a hole: punching a circular through hole on the edge of the wrapping paper cut in step S2 by punching;

[0043] S4, folding and creasing: according to the folding method of the packaged beverage box, the packaging paper in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com