Blast furnace stockhouse arrangement

一种储藏室、供给装置的技术,应用在特别是高炉的储藏室装置,冶金炉领域,能够解决自动化储藏室复杂等问题,达到灵活适应性、便于维护、减少投资成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

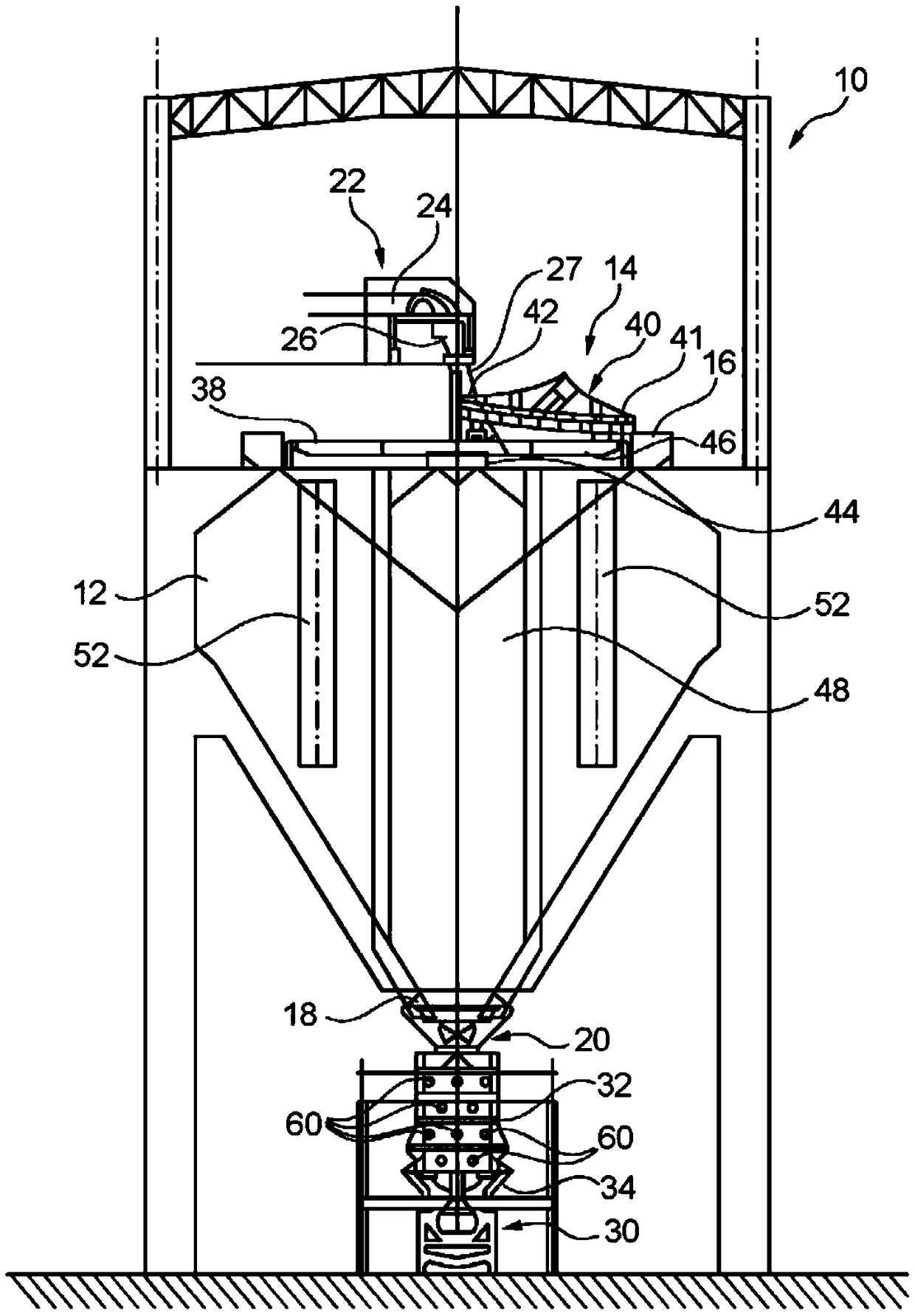

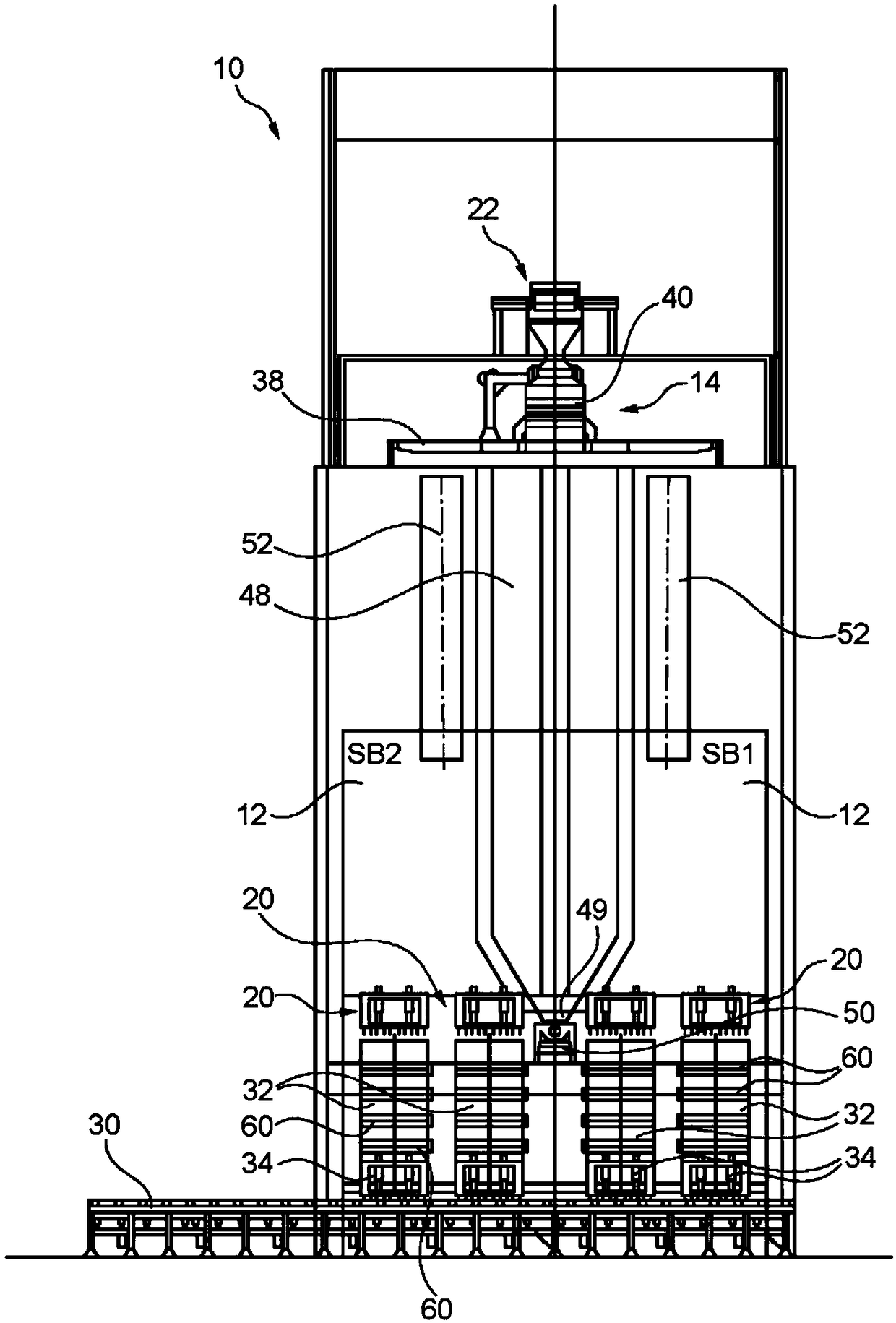

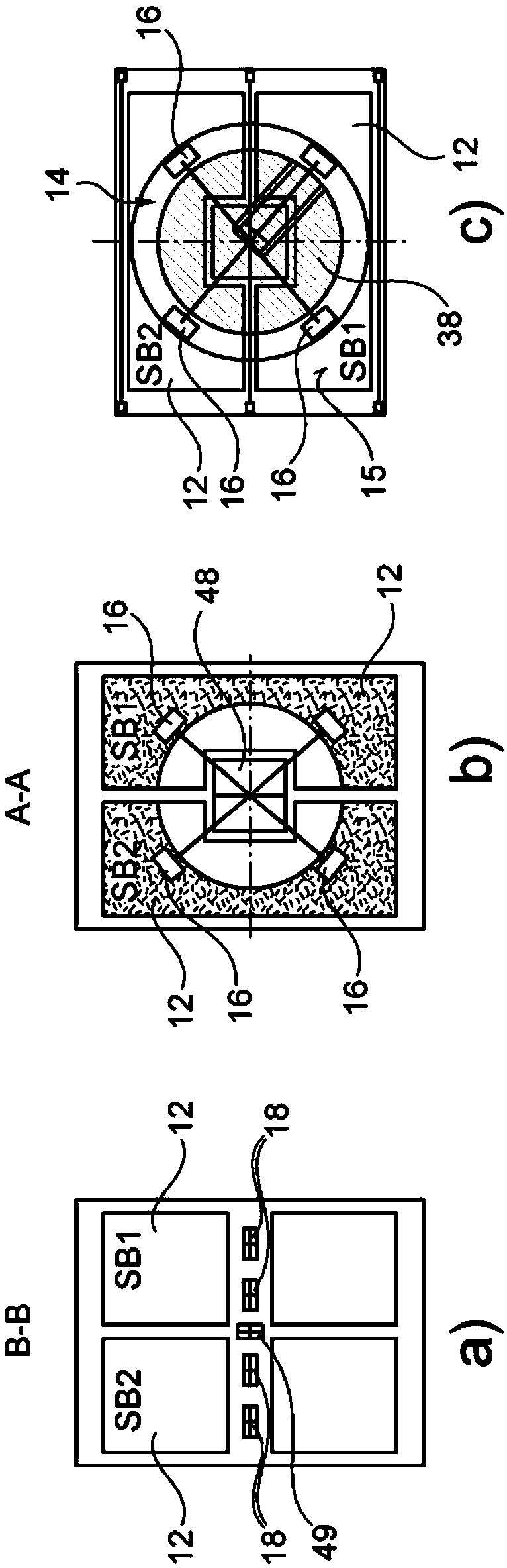

[0042] Figure 1 to Figure 3 An embodiment of the present storeroom arrangement 10 for storing, measuring and preparing charge materials for metallurgical furnaces, in particular for blast furnace workshops, is shown.

[0043] A blast furnace area with such a material storage device is commonly referred to as a storeroom; the terms "storeroom", "storehouse arrangement", "storeroom system" and "material storage facility" will be used herein without distinction.

[0044] The storage room 10 comprises a set of storage bins 12 arranged in a side-by-side manner to be filled by a material supply 14 associated therewith. The storage silo 12 has a generally funnel-like form that converges towards its lower end. The storage silo 12 has a large capacity, generally above 200 cubic meters, for example between 300 and 600 cubic meters, and even between 500 and 1000 cubic meters. The storage silo 12 is closed at its top by a cover 15 in which a supply opening 16 is arranged; and has a nar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com