Anti-falling structure for hopper

A hopper and anti-fall technology, used in elevators, transportation and packaging, etc., can solve problems such as hidden safety hazards and free fall from a height of 7 to 8 meters, so as to avoid free fall and improve the safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

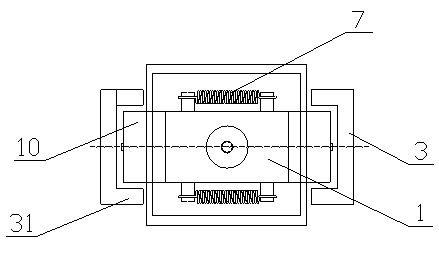

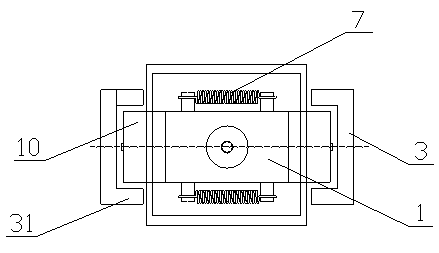

[0028] The anti-fall structure of the hopper of this embodiment includes a hopper 1 and a lifting bracket. The hopper 1 is connected with a lifting rope 2 so that the hopper 1 can be lifted or lowered under the action of the lifting rope; the lifting bracket is provided with a vertical guide 3, a guide rail 3 There are multiple locking through holes 4 at intervals; the side wall of the hopper 1 is provided with pin through holes 5 at the position corresponding to the guide rail 3, and the hopper 1 is provided with a stop pin 6 that can be inserted into the locking through hole 4, When the lifting rope 2 performs a pulling action, the stop pin 6 can be driven to exit the driving part of the locking through hole 4, and when the lifting rope 2 is broken, the stop pin 6 can be driven to pass through the pin through hole 5 and extend to the locking through hole 4 The reset section.

[0029] Specifically, there are two stop pins 6 and they are arranged opposite to each other. The drivi...

Embodiment 2

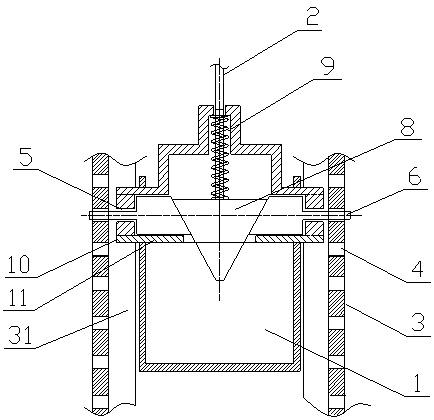

[0034] The anti-fall structure of the hopper of this embodiment includes a hopper 1 and a lifting bracket. The hopper 1 is connected with a lifting rope 2 so that the hopper 1 can be lifted or lowered under the action of the lifting rope; the lifting bracket is provided with a vertical guide 3, a guide rail 3 There are multiple locking through holes 4 at intervals; the side wall of the hopper 1 is provided with pin through holes 5 at the position corresponding to the guide rail 3, and the hopper 1 is provided with a stop pin 6 that can be inserted into the locking through hole 4, When the lifting rope 2 performs a pulling action, the stop pin 6 can be driven to retract into the driving part of the hopper 1, and when the lifting rope 2 is broken, the stop pin 6 can be driven to pass through the pin through hole 5 and extend to the stop through hole 4 Reset department.

[0035] Specifically, there are two stop pins 6 and they are arranged opposite to each other. The driving part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com