Coating thickness test method

A coating thickness and testing method technology, applied in the coating thickness testing field, can solve problems such as inability to measure multiple metal coatings at the same time, inability to reflect coating thickness as a whole, and accurate characterization of unfavorable components, and achieve wide thickness range and high accuracy , the effect of less interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

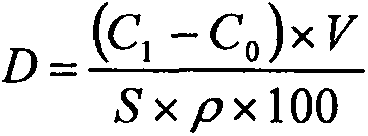

Method used

Image

Examples

Embodiment 1

[0046] 1. Preparation of sample blocks

[0047] Select two representative positions on the shrapnel sample, and intercept two rectangular samples. Repair the plated part of the sample block to make it smooth and regular without burrs.

[0048] 2. Measuring the coating area

[0049] Use a vernier caliper to precisely measure the coating position of the sample block. The side lengths of the two sample blocks are 0.729cm, 0.758cm and 0.646cm, 0.728cm respectively. Calculate the area S of the coating of the sample block according to the area formula.

[0050] 3. Sample block digestion

[0051] Put the two sample blocks into 100ml clean beakers respectively, add 5ml of concentrated nitric acid and 1ml of concentrated hydrochloric acid, heat the beaker on a heating plate (the temperature of the heating plate is about 150°C), until the sample block is completely digested. Take it off and cool to room temperature, rinse the inner wall of the beaker with the first-class water specif...

Embodiment 2

[0070] 1. Preparation of sample blocks

[0071] The electronic product jumper is a regular rectangular small sample. The front and back of the sample are coated. This sample is directly tested as a whole without cutting samples.

[0072] 2. Measuring the coating area

[0073] Use a vernier caliper to precisely measure the coating position of the sample block. The side lengths of the two sample blocks are 0.400cm, 0.235cm and 0.411cm, 0.235cm respectively. There are coatings on both sides of the sample block. Calculate the area of the sample block coating according to the area formula S.

[0074] 3. Sample block digestion

[0075] Put the two sample blocks into 100ml clean beakers respectively, add 5ml of concentrated nitric acid and 1ml of concentrated hydrochloric acid, heat the beaker on a heating plate (the temperature of the heating plate is about 150°C), until the sample block is completely digested. Take it off and cool to room temperature, rinse the inner wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com