High bulk density carbonyl iron powder for 3D printing and preparation method thereof

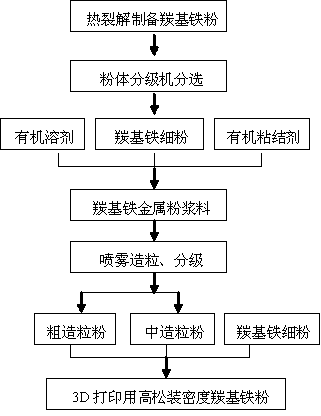

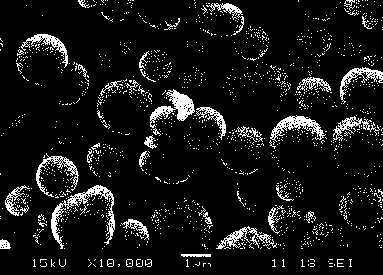

A technology of carbonyl iron powder and 3D printing, which is applied in transportation and packaging, metal processing equipment, additive processing, etc. It can solve the problem of not meeting the requirements of high bulk density of metal powder, not meeting the requirements of fast 3D printing, and the original particle size of metal powder Large and other problems, to achieve the effect of low cost, high sphericity, and small original particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The carbonyl iron powder is prepared by pyrolysis of iron pentacarbonyl, and the oxygen content of the obtained carbonyl iron powder is 0.5%; the obtained carbonyl iron powder is sorted by a powder classifier, and the selected particle size is less than 5 microns (D90 is 4.21 microns) ) of carbonyl iron powder as a fine powder.

[0029] Carbonyl iron fine powder with a particle size of less than 5 microns is mixed with polyvinyl butyral and absolute ethanol to make a carbonyl iron powder slurry, wherein the amount of polyvinyl butyral is 0.5% of the mass of carbonyl iron, carbonyl The mass ratio of iron powder to absolute ethanol is 5:1.

[0030] The carbonyl iron powder slurry is made into carbonyl iron spherical granulation powder through a closed cycle spray granulator; the carbonyl iron spherical granulation powder is screened with a 100-mesh and 200-mesh vibrating screen, and the particle size range is 75-150 microns. The carbonyl iron spherical granulated powder ...

Embodiment 2

[0033] The carbonyl iron powder is prepared by pyrolysis of iron pentacarbonyl, and the oxygen content of the carbonyl iron powder is 0.4%; the obtained carbonyl iron powder is sorted by a powder classifier, and the selected particle size is less than 5 microns (D90 is 3.87 microns) ) of carbonyl iron powder as a fine powder.

[0034] Mix carbonyl iron fine powder with a particle size of less than 5 microns with nitrocellulose and xylene to make carbonyl iron powder slurry, wherein the amount of nitrocellulose is 5% of the mass of carbonyl iron, and the mass ratio of carbonyl iron powder to xylene is 0.5:1.

[0035] The carbonyl iron powder slurry is made into carbonyl iron spherical granulation powder through a closed cycle spray granulator; the carbonyl iron spherical granulation powder is screened with a 100-mesh and 200-mesh vibrating screen, and the particle size range is 75-150 microns. The carbonyl iron spherical granulated powder is used as coarse powder; the carbonyl...

Embodiment 3

[0038] The carbonyl iron powder is prepared by pyrolysis of iron pentacarbonyl, and the oxygen content of the carbonyl iron powder is 0.5%; the obtained carbonyl iron powder is sorted by a powder classifier, and the selected particle size is less than 5 microns (D90 is 4.18 microns) ) of carbonyl iron powder as a fine powder.

[0039] Carbonyl iron fine powder with a particle size of less than 5 microns is stirred and mixed with ethyl acetate and toluene to make a carbonyl iron powder slurry, wherein the amount of ethyl acetate is 2% of the mass of carbonyl iron, and the mass ratio of carbonyl iron powder to toluene is 2:1.

[0040] The carbonyl iron powder slurry is made into carbonyl iron spherical granulation powder through a closed cycle spray granulator; the carbonyl iron spherical granulation powder is screened with a 100-mesh and 200-mesh vibrating screen, and the particle size range is 75-150 microns. The carbonyl iron spherical granulated powder is used as coarse pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com