Preparation method of silicon carbide ceramic hollow fiber membrane reinforced and toughened by silicon carbide whiskers

A technology of silicon carbide whiskers and silicon carbide ceramics, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low ceramic hollow fiber membrane strength, low effective filtration area, and difficult packaging, etc., to achieve The effect of shortening the permeation path, reducing the permeation resistance of the membrane, and increasing the packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

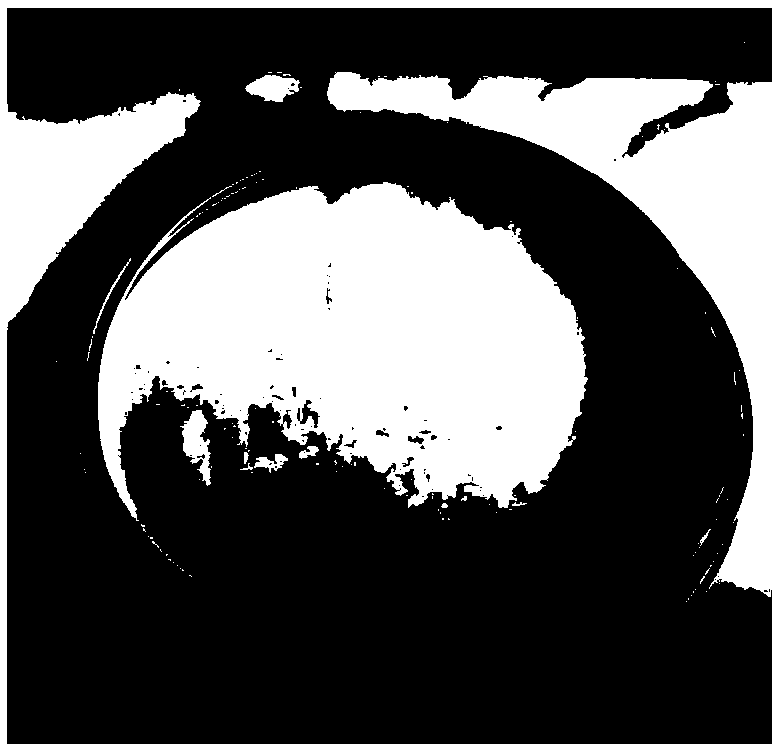

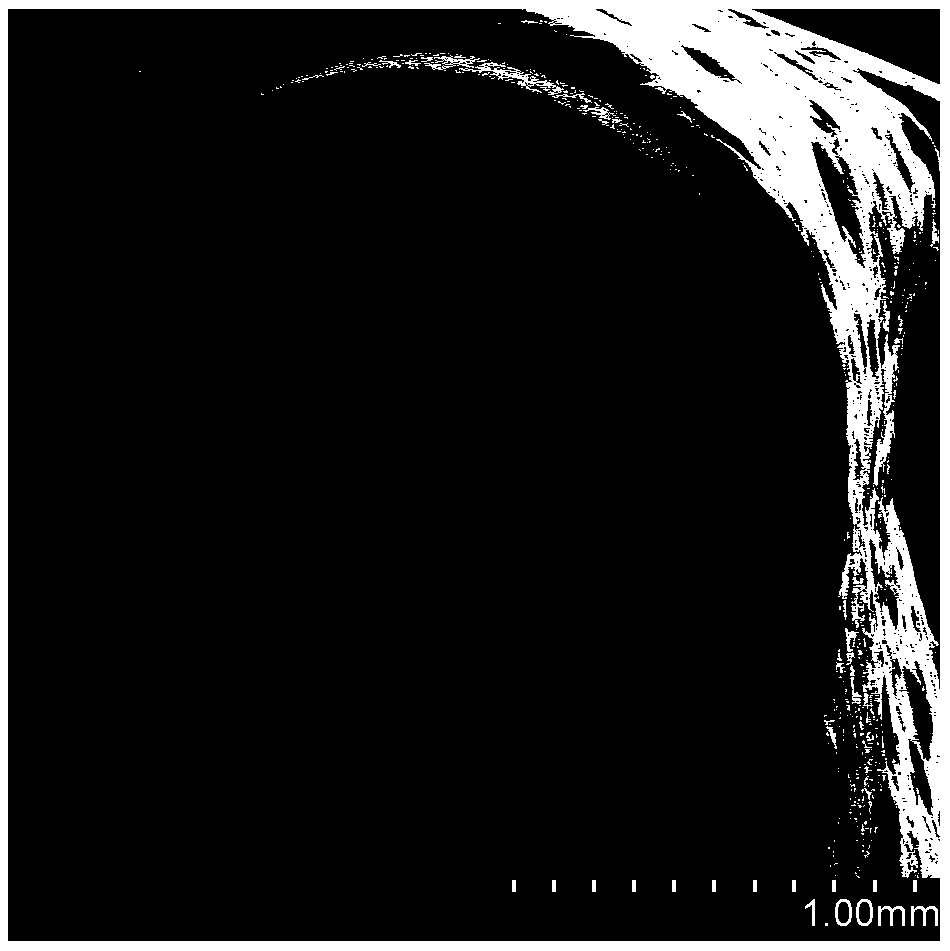

Image

Examples

preparation example Construction

[0029] A method for preparing a silicon carbide ceramic hollow fiber membrane reinforced and toughened by silicon carbide whiskers, comprising the following steps:

[0030] (1) Polyethersulfone (5%-10%, mass fraction), N-methyl-pyrrolidone (35%-40%), silicon carbide powder (30%-60%) and silicon carbide whiskers (supplement 100%) mixing, ball milling for 2-10 hours to make it evenly mixed, and then continuously stirring to fully disperse the solid particles in the polymer solution to obtain a uniformly dispersed spinning solution, that is, the cast film slurry;

[0031] (2) Add the cast film slurry to the spinning device, vacuumize for 0.5-2h to remove the residual air bubbles, then pass the inner gelling agent into the spinning device, apply 0.1-0.6bar nitrogen pressure to cast The film slurry is squeezed into the spinneret, and the fiber wet film extruded from the spinneret is immersed in an external coagulation bath through a 0-20cm dry spinning process for 12-36h of gelatio...

Embodiment 1

[0036] 0% SiC whisker reinforced and toughened SiC ceramic hollow fiber membrane

[0037] (1) Mix polyethersulfone (10%, referring to its mass percentage in the casting film slurry, the same below), N-methyl-pyrrolidone (40%), mix them by wet ball milling for 6 hours, and dissolve them completely Polymer solution, adding silicon carbide powder (50%) with an average particle size of 1 μm to the above polymer solution, stirring continuously to fully disperse the solid particles in the polymer solution, and obtain a uniformly dispersed spinning solution, that is, casting slurry material.

[0038] (2) Add the prepared cast film slurry into the slurry tank on the spinning device, first vacuumize for 2 hours to remove the residual air bubbles, then pass through the inner gelling agent water, and finally apply a nitrogen pressure of 0.1 bar, from the spinneret The extruded fiber wet membrane is immersed in the water of an external coagulation bath through a 10 cm dry spinning proces...

Embodiment 2

[0041] 5% SiC Whisker Reinforced and Toughened SiC Ceramic Hollow Fiber Membranes

[0042] (1) After mixing polyethersulfone (10%) and N-methyl-pyrrolidone (40%), wet ball milling and mixing for 6 hours to completely dissolve it to form a polymer solution, and add the average particle size to the above polymer solution Silicon carbide powder (45%) of 5 μm and silicon carbide whiskers (5%) with an average length of 10 μm and an average diameter of 1 μm, continuous stirring to fully disperse the solid particles in the polymer solution, and obtain a uniformly dispersed spinning solution That is, casting film slurry.

[0043] (2) Add the prepared cast film slurry into the slurry tank on the spinning device, first vacuumize for 2 hours to remove residual air bubbles, then pass through the inner gelling agent ethanol, and finally apply a nitrogen pressure of 0.1bar, from the spinneret The extruded fiber wet membrane is dipped in ethanol in an external coagulation bath through a 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com