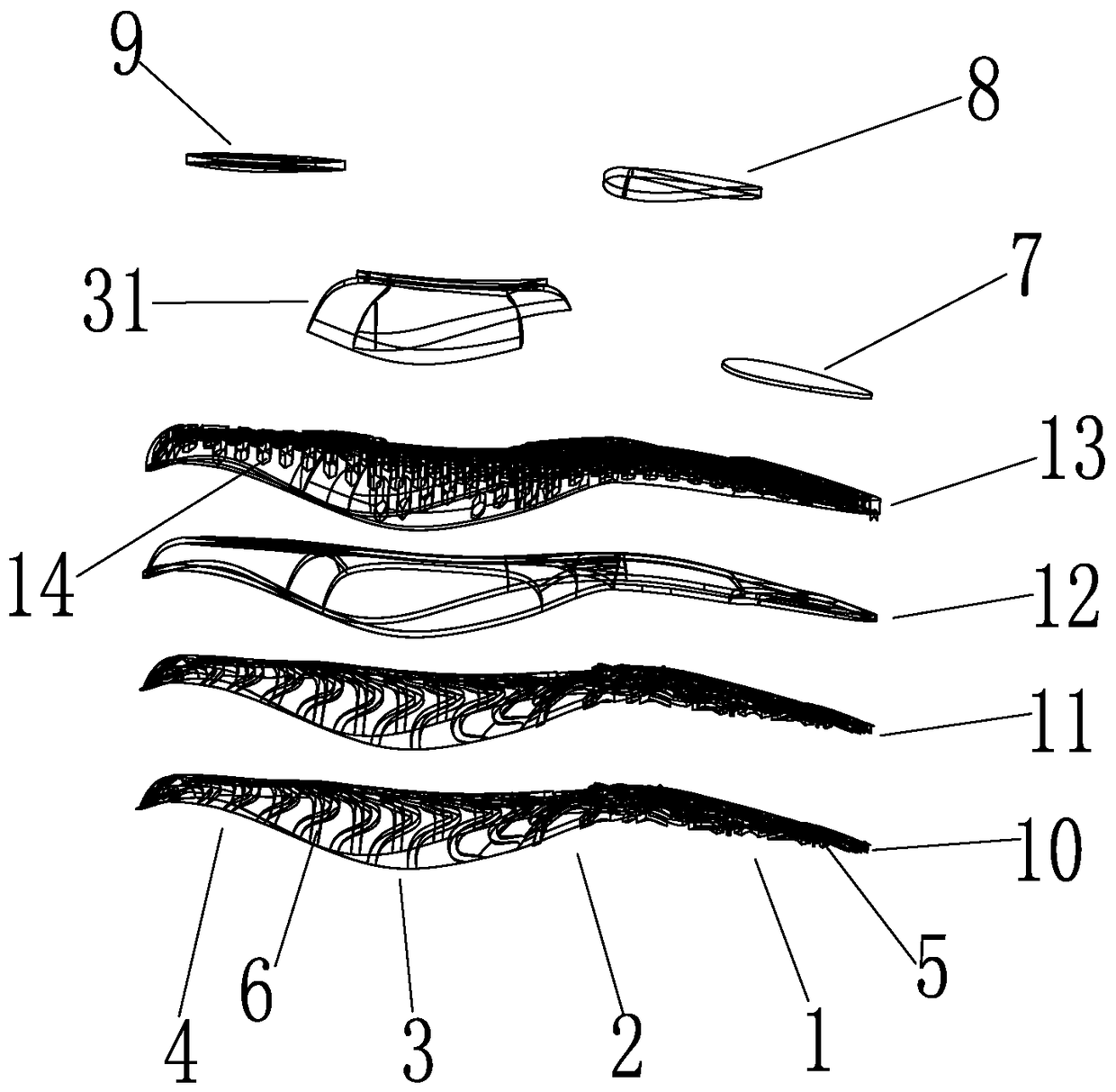

Badminton insole

A badminton and insole technology, applied in the field of insoles, can solve the problems of difficulty in protecting plantar bones, ankle joints and knee joints, injuries of plantar bones, ankle joints and knee joints, large impact force on the forefoot and heel bottom of the foot, etc. To achieve the effect of reducing accidental injuries to the foot joints, refreshing the feet, and having a good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation steps of the forefoot shock absorbing pad 7 and the memory foam layer 12 are:

[0036] 1) Prepare materials according to the following raw materials in parts by weight: 65 parts of polyether polyol, 15 parts of isosorbide, 25 parts of methyl tert-butyl ether, 12 parts of mineral mint powder, 25 parts of polymethylene polyisocyanate, 12 parts of 1,5-pentamethylene diisocyanate, 2 parts of 99% pure triethanolamine, 1 part of ethylene glycol, 1.5 parts of foaming agent, 0.2 parts of high resilience silicone oil, 0.1 part of potassium hydroxide;

[0037] 2) Stirring and mixing: first add the weighed polyether polyol, isosorbide, methyl tert-butyl ether, mineral mint powder, polymethylene polyisocyanate, and 1,5-pentamethylene diisocyanate to the Stir and mix evenly in the iron container until the material liquid has no bubbles, then add 99% pure triethanolamine, ethylene glycol, foaming agent, high resilience silicone oil, potassium hydroxide and other auxil...

Embodiment 2

[0044] Nano bamboo charcoal fiber layer 10 is made up of bamboo charcoal fiber, nano silver fiber, single crystal sapphire whisker and viscose fiber; Contain 0.8 part of ceramic powder and coupling agent in viscose fiber, coupling agent is 0.3% of ceramic powder weight; The powder is made of the following parts by weight: 40 parts of zirconium dioxide, 35 parts of silicon dioxide, 5 parts of titanium dioxide, 5 parts of magnesium oxide, 5 parts of zinc oxide, 5 parts of baking soda, and 5 parts of manganese dioxide; the coupling agent is Glyceryl Stearate;

[0045] The preparation method of the viscose fiber is as follows: (1) Mix zirconium dioxide, silicon dioxide, titanium dioxide, magnesium oxide, zinc oxide, baking soda and manganese dioxide, sinter and crush until the average particle size is 1- 2μm ceramic powder; (2) Mix the coupling agent with the ceramic powder to obtain a modified ceramic powder; (3) Blend the modified ceramic powder with viscose, extrude and slice, ...

Embodiment 3

[0048] The mid-waist pad 31 includes the following components by weight: 25 parts of celery fiber, 30 parts of nano-bamboo charcoal fiber, 1 part of acetate fiber, 2 parts of polypropylene fiber, 20 parts of wood wool powder, 6 parts of resin glue, hydroxypropyl fiber 1 part of vegetable, 0.1 part of glycerin, 0.1 part of chitosan quaternary ammonium salt, 1 part of chitin, 1 part of Cyperus cyperus powder.

[0049] The upper side of the nano bamboo charcoal fiber layer 10 of the insole body is provided with an anti-slip film, and the anti-slip film is made of 20 parts of polypropylene, 15 parts of maleic anhydride grafted polypropylene, 8 parts of acrylonitrile, polydicyclopentadiene 10 parts, 5 parts of cyclohexyl alcohol, 8 parts of silicone resin, 5 parts of molybdenum disulfide, 3 parts of boric acid, 2 parts of anti-sticking agent, 3 parts of active agent are made, and described anti-sticking agent selects synthetic moissanite for use, and described The active agent is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com