Method for continuously reducing temperature rise in using process of accumulator

A technology of temperature rise and storage battery, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of inability to conduct heat in time and the active material of the battery falls off, and achieve reasonable cost, low input cost and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

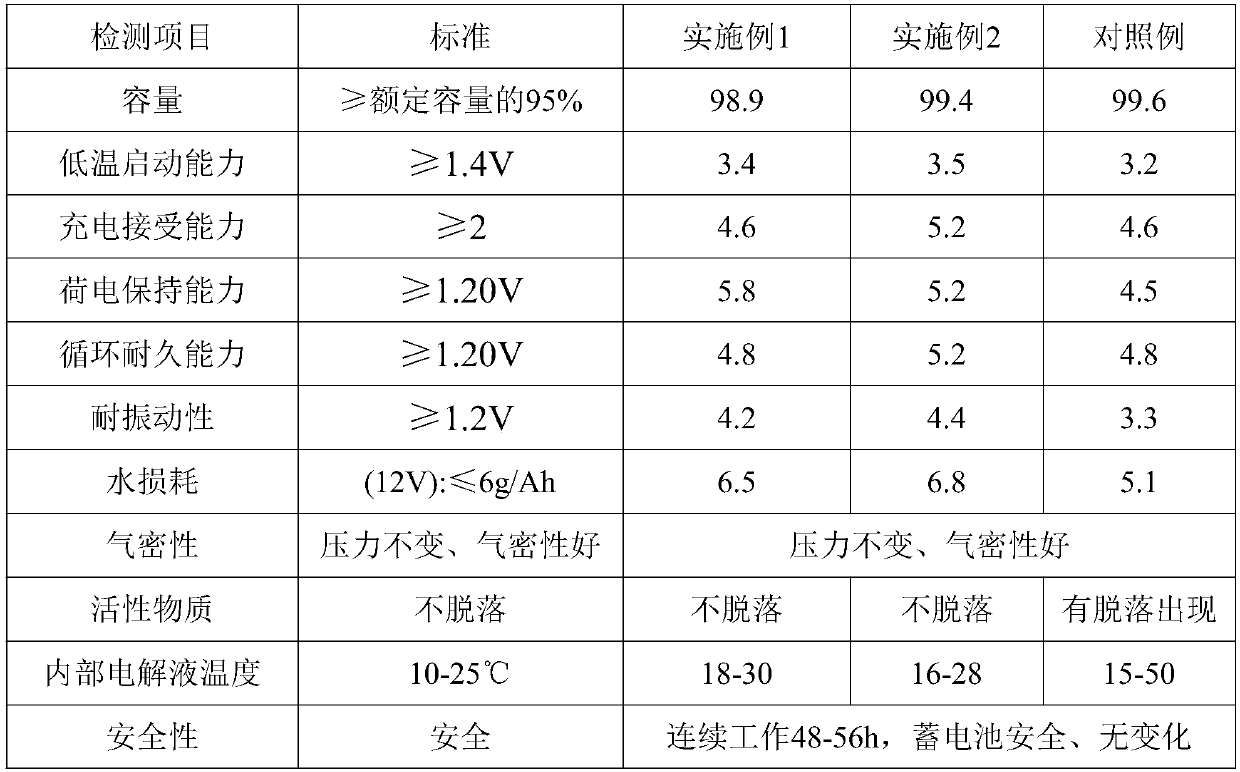

Examples

Embodiment 1

[0031] The invention provides a method for continuously reducing the temperature of battery electrode plates, which is realized by the following method: add a layer of protective layer shell to the battery shell, and leave a gap of 0.3-1cm between the protective layer shell and the battery shell. filled with liquid nitrogen.

[0032] Wherein the protective layer shell includes the following components by mass: 15 parts of stearic acid, 16 parts of aromatic essential oil, 12 parts of charcoal ash, 7 parts of calcium peroxide, 40 parts of terpene resin modified volcanic ash, and 3 parts of microcrystalline cellulose , 2.5 parts of crospovidone, 2 parts of sepiolite fiber, 1 part of polyvinyl alcohol resin, 4 parts of salicylic acid, 1.5 parts of hydrogenated rosin pentaerythritol ester, 1 part of polytetrafluoroethylene superfine powder, 2 parts of polylactic acid , 0.8 parts of diphenylmethane bismaleimide, 0.5 parts of sulfated castor oil, 0.3 parts of allyl glycidyl ether, 0....

Embodiment 2

[0049] The invention provides a method for continuously reducing the temperature of battery electrode plates, which is realized by the following method: add a layer of protective layer shell to the battery shell, and leave a gap of 0.3-1cm between the protective layer shell and the battery shell. filled with liquid nitrogen.

[0050] Wherein the protective layer shell includes the following components by mass: 6 parts of stearic acid, 15 parts of aromatic essential oil, 10 parts of charcoal ash, 7 parts of calcium peroxide, 40 parts of terpene resin modified volcanic ash, and 2 parts of microcrystalline cellulose , 3 parts of crospovidone, 2 parts of sepiolite fiber, 1.5 parts of polyvinyl alcohol resin, 6 parts of salicylic acid, 1 part of hydrogenated rosin pentaerythritol ester, 0.5 part of polytetrafluoroethylene superfine powder, 5 parts of polylactic acid , 1 part of diphenylmethane bismaleimide, 0.8 part of sulfated castor oil, 0.4 part of allyl glycidyl ether, 0.5 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com