A single-layer wear-resistant seamless steel pipe for concrete pump truck and its manufacturing method

A technology for concrete pump trucks and seamless steel pipes, which is applied in the field of seamless steel pipe production, can solve problems such as poor crack resistance, poor wear resistance and poor toughness of steel pipes, achieve good wear resistance, and reduce low-temperature tempering processes , The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with embodiment:

[0029] A single-layer wear-resistant seamless steel pipe for concrete pump trucks, the chemical composition of the steel contains: 0.50% to 0.60% of C, 0.15% to 0.35% of Si, 0.60% to 0.90% of Mn, and 0.25% to Cr 0.50%, Ti0.010%~0.030%, the balance is Fe and unavoidable impurities.

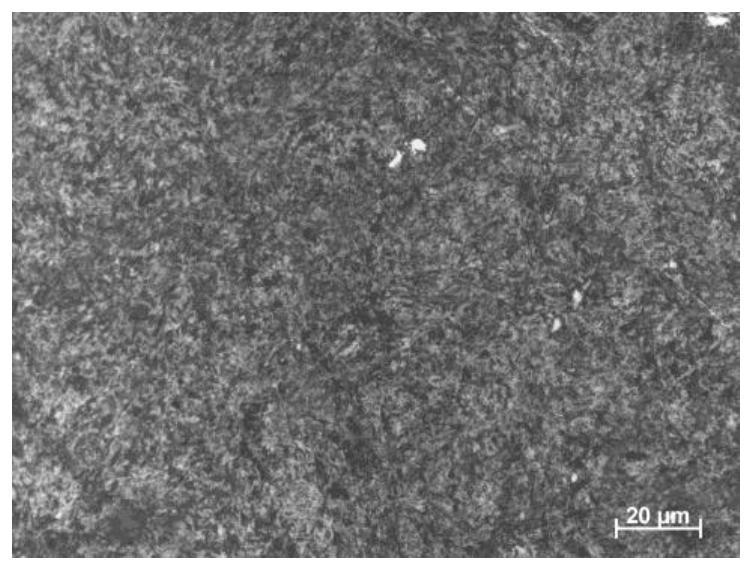

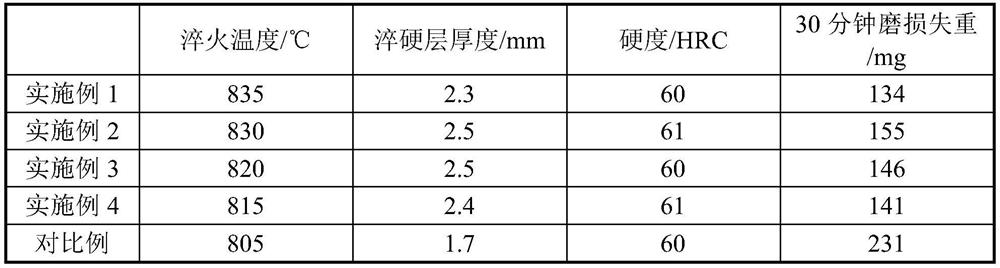

[0030] The inner surface of the finished steel pipe has a mixed structure of martensite + troostite, the thickness of the mixed structure reaches 2-3.5mm, and the hardness value is HRC55-62. The hardened structure is a mixed structure of martensite and troostite, troostite accounts for 40%-60% of the mixed structure, the structure is better than pure martensite, the hardness of the hardened layer reaches HRC55-62, and the structure It has a certain toughness. Compared with the simple martensitic hardened layer, it reduces the cracks on the inner surface of the steel pipe due to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com