Culture medium composition containing fermentation mother solution as well as production method and fermentation method thereof

A culture medium and composition technology, applied in the field of re-fermentation and utilization of fermented yeast liquid, can solve the problems of increasing the economic and environmental burden of enterprises, high daily operating costs, and the application of complete sets of technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

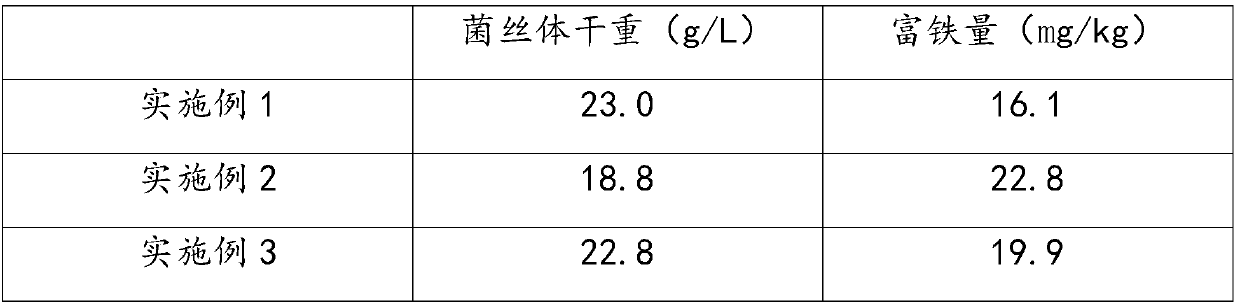

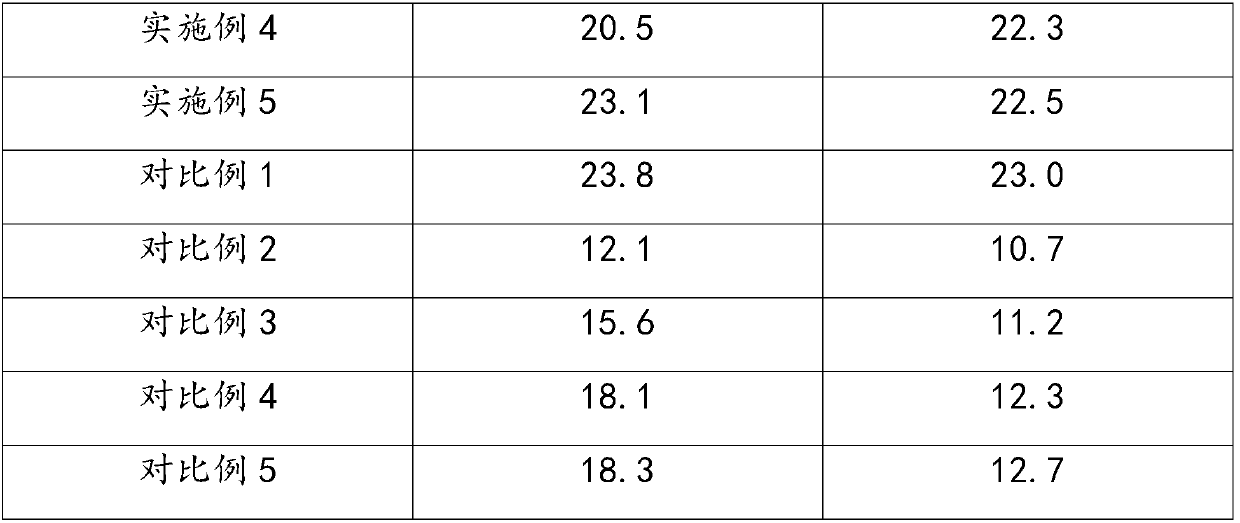

Embodiment 1

[0029] Add 0.06g of broken iron-rich yeast and 30g of corn superfine powder to 1L of Agaricus blazei mycelium liquid yeast solution, sterilize at 121°C for 30 minutes, and then cool.

[0030] The Agaricus blazei seeds were inoculated into the above-mentioned liquid medium, and liquid fermentation was carried out at a temperature of 25°C, aeration and stirring, and a fermentation time of 15 days. The cultured fermentation broth was centrifuged at 2000 rpm for processing, and the mycelium was collected, washed and dried to obtain organic enrichment. Agaricus blazei mycelium.

Embodiment 2

[0032] Add 0.18 g of broken iron-rich yeast and 10 g of corn superfine powder to 1L of Agaricus blazei mycelium liquid yeast, sterilize at 121°C for 15 minutes and then cool.

[0033] The Agaricus blazei seeds were inoculated into the above-mentioned liquid medium, and liquid fermentation was carried out at a temperature of 27°C, aeration and stirring, and a fermentation time of 3 days. The cultured fermentation broth was centrifuged at 10000 rpm, and the mycelium was collected, washed and dried to obtain organic enrichment. Agaricus blazei mycelium.

Embodiment 3

[0035] Add 0.09g of broken iron-rich yeast and 25g of corn superfine powder to 1L of Agaricus blazei mycelium liquid yeast, sterilize at 121°C for 20 minutes, and then cool.

[0036] The Agaricus blazei seeds were inoculated into the above-mentioned liquid medium, and the liquid fermentation was carried out at a temperature of 25°C, aeration and stirring, and a fermentation time of 5 days. The cultured fermentation broth was subjected to plate and frame pressure filtration with a pressure of 60 kg, and the mycelium was collected. Washing and drying to obtain organic Agaricus blazei mycelium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com