Raw material and manufacturing process for reinforced slings

A lifting belt, enhanced technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of insufficient damage resistance of the lifting belt, insufficient rotation bending fatigue strength and contact fatigue strength, etc., to prevent the transfer from taking a long time Large, improved transmission effect, strong anti-destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

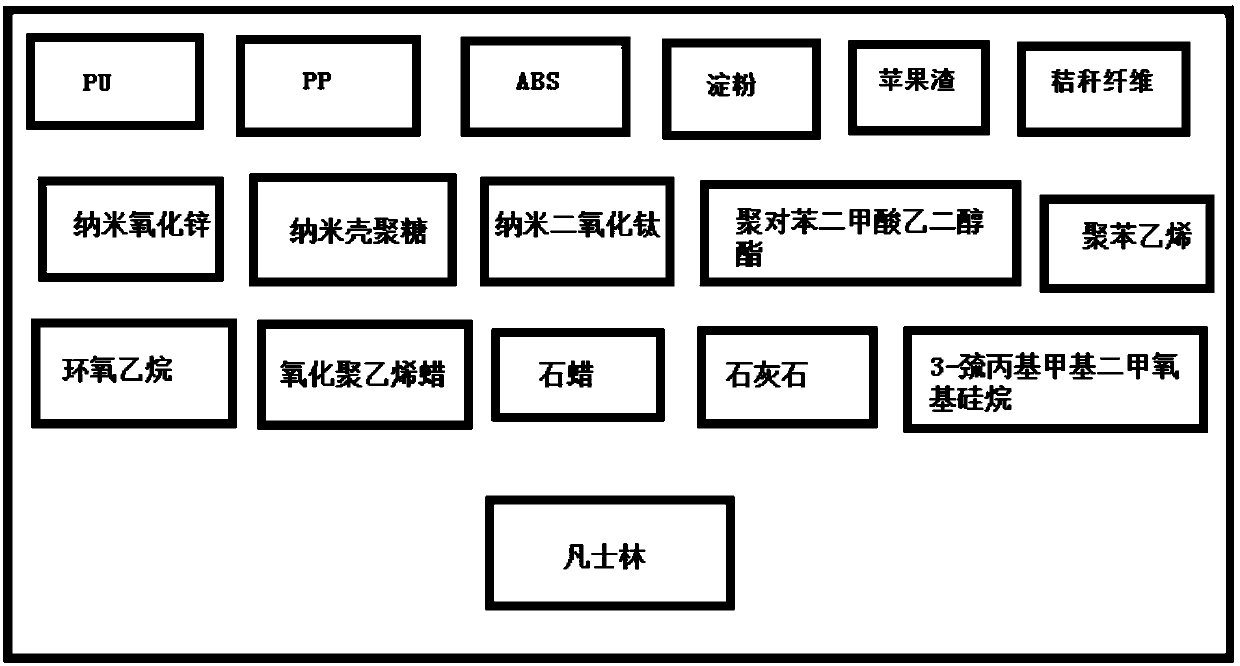

[0062] Such as figure 1 As shown, the raw materials of the enhanced sling, the raw materials of the enhanced sling include: 12 parts by weight of PU, 8 parts by weight of PP, 8 parts by weight of ABS, 8 parts by weight of 72 parts of starch, 6 parts by weight of apple pomace, 16 parts of straw fiber, 2 parts of nano-zinc oxide, 18 parts of nano-chitosan, weight Parts are 8 parts of nano-titanium dioxide, parts by weight of polyethylene terephthalate 92 parts, polystyrene of 18 parts by weight, ethylene oxide of 2 parts by weight, Parts are 1 part of oxidized polyethylene wax, 0.8 parts of paraffin, 12 parts of limestone, 1 part of 3-mercaptopropylmethyldimethoxysilane and weight 2 parts petroleum jelly.

[0063] The manufacturing steps of the enhanced sling include the following steps:

[0064] Step a, the PU that is 12 parts by weight, the PP that is 8 parts by weight, the ABS that is 8 parts by weight, the starch that is 72 parts by weight, the apple pomace that is 6 part...

Embodiment 2

[0073] The raw materials of the enhanced sling, the raw materials of the enhanced sling include: 14 parts by weight of PU, 12 parts by weight of PP, 12 parts by weight of ABS, 85 parts by weight starch, 9 parts by weight of apple pomace, 20 parts by weight of straw fiber, 3 parts by weight of nano-zinc oxide, 20 parts by weight of nano-chitosan, and 20 parts by weight of nano-chitosan. 11 parts of nano-titanium dioxide, parts by weight of polyethylene terephthalate of 102 parts, parts by weight of polystyrene, parts by weight of ethylene oxide of 5 parts, parts by weight of 4 parts of oxidized polyethylene wax, 1.1 parts by weight of paraffin, 13 parts of limestone, 2 parts of 3-mercaptopropylmethyldimethoxysilane and 2 parts by weight of 3 parts petroleum jelly.

[0074] The manufacturing steps of the enhanced sling include the following steps:

[0075] Step a, the PU that is 14 parts by weight, the PP that is 12 parts by weight, the ABS that is 12 parts by weight, the star...

Embodiment 3

[0084] The raw materials of the enhanced sling, the raw materials of the enhanced sling include: 12-16 parts by weight of PU, 8-16 parts by weight of PP, 8-16 parts by weight of ABS, 72-98 parts by weight of starch, 6-12 parts by weight of apple pomace, 16-24 parts by weight of straw fiber, 2-4 parts by weight of nano-zinc oxide, parts by weight of 18-22 parts of nano-chitosan, 8-14 parts by weight of nano-titanium dioxide, 92-112 parts of polyethylene terephthalate, 18-24 parts by weight parts by weight of polystyrene, 2-8 parts by weight of ethylene oxide, 1-7 parts by weight of oxidized polyethylene wax, 0.8-1.4 parts by weight of paraffin wax, 12 parts by weight - 14 parts of limestone, 1-3 parts by weight of 3-mercaptopropylmethyldimethoxysilane and 2-4 parts by weight of petrolatum.

[0085] The manufacturing steps of the enhanced sling include the following steps:

[0086] Step a, the PU that is 12-16 parts by weight, the PP that is 8-16 parts by weight, the ABS that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com