Preparation method of toughness-enhanced melamino-formaldehyde-polyvinyl alcohol composite foam material

A technology of melamine formaldehyde and polyvinyl alcohol, which is applied in the field of foam, can solve the problems of low water absorption, unfavorable mass production, cumbersome preparation process steps, etc., and achieve the effect of improved toughness and excellent damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a kind of preparation method of melamine formaldehyde-polyvinyl alcohol composite foam material, comprises the following steps:

[0018] The melamine formaldehyde foam is soaked in the polyvinyl alcohol aqueous solution, after the absorption is saturated, then soaked in the crosslinking agent solution, solidifies and crosslinks, and obtains the melamine formaldehyde-polyvinyl alcohol composite foam material;

[0019] The degree of alcoholysis of the polyvinyl alcohol is 60-99%, the molecular weight is 10000-250000, and the viscosity is 2.0-125.0mPa·s;

[0020] The crosslinking agent is selected from one or more of urea, boric acid, citric acid, formic acid, formaldehyde, glyoxal, glutaraldehyde and calcium chloride.

[0021] The present invention provides and adopts commercially cheap melamine formaldehyde foam (MF) and polyvinyl alcohol (PVA) as raw material, utilizes the secondary amine group (-NH-) in the hydroxyl (-OH) in the PVA molecule and ...

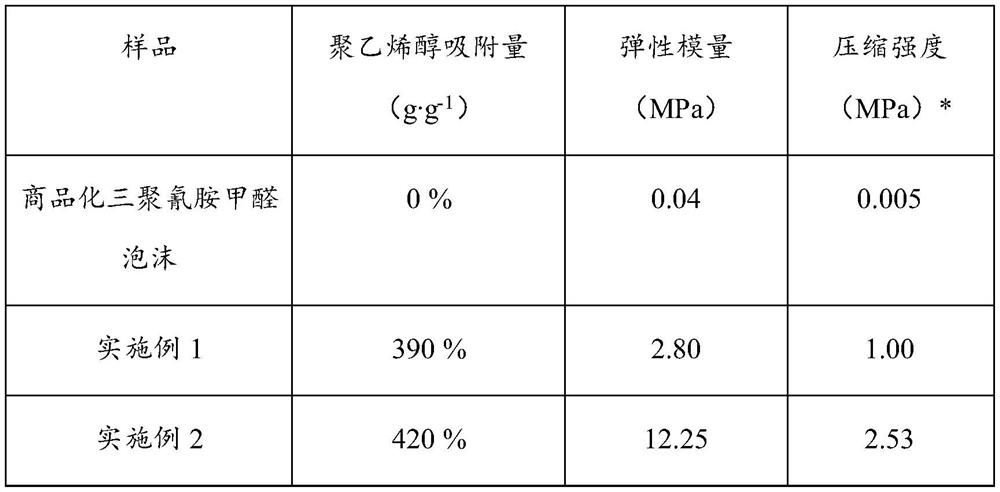

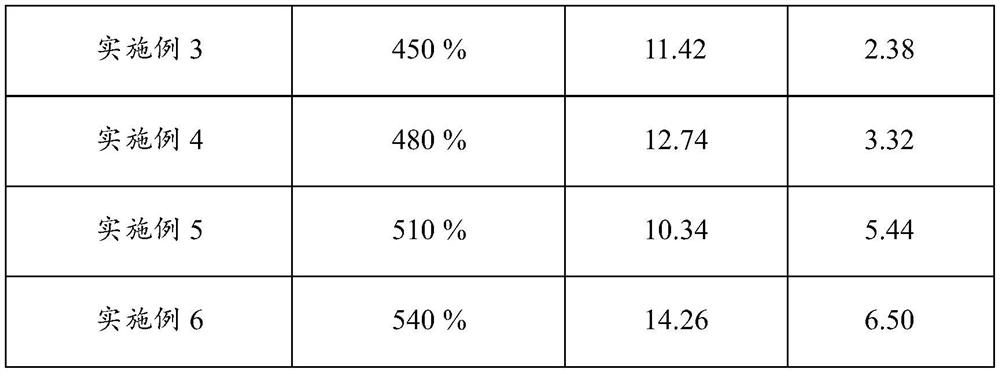

Embodiment 1

[0036] Embodiment 1: boric acid / calcium chloride compound preparation melamine formaldehyde-polyvinyl alcohol composite foam:

[0037]Accurately weigh 10.0g polyvinyl alcohol (PVA) raw material (alcoholysis degree is 99%, molecular weight 10000), add 90.0g deionized water, set the oil bath temperature at 95°C, heat and dissolve for 6 hours to prepare a 10.0% PVA aqueous solution , take by weighing 5.0g commercialization melamine formaldehyde (MF) foam material and fully soak and absorb in the above-mentioned PVA aqueous solution, take out, transfer rapidly to in the 100g 5.0% composite linking agent solution prepared by 2.0g boric acid and 3.0g calcium chloride, And put it in an oven at 80°C for curing and crosslinking for 10 hours, take out the cured and crosslinking melamine formaldehyde-polyvinyl alcohol foam material, wash it repeatedly with deionized water to remove unreacted raw material PVA and crosslinking agent, and dry it in an oven at 50°C for 6 hours, collect The p...

Embodiment 2

[0038] Embodiment 2: urea / glyoxal compound preparation melamine formaldehyde-polyvinyl alcohol composite foam:

[0039] Accurately weigh 15.0g polyvinyl alcohol (PVA) raw material (alcoholysis degree is 95%, molecular weight 60000), add 85.0g deionized water, set the oil bath temperature at 95°C, heat and dissolve for 5 hours to prepare a 15.0% PVA aqueous solution , take by weighing 5.0g commercialization melamine formaldehyde (MF) foam material and fully soak and absorb in the above-mentioned PVA aqueous solution, take out, transfer to rapidly in the 100g 10.0% composite linking agent solution prepared by 5.0g urea and 5.0g glyoxal, And put it in a 70°C oven to cure and crosslink for 24 hours, take out the cured and crosslinked melamine formaldehyde-polyvinyl alcohol foam material, wash it repeatedly with deionized water to remove unreacted raw material PVA and crosslinking agent, and dry it in a 50°C oven for 6 hours, collect The product, marked as MF-PVA-2, was subjected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com