Fibrous Ti3C2 MXene-based torsion angle sensor and preparation method thereof

A technology of torsion angle and sensors, applied in the field of sensors, to achieve the effects of improving economic benefits, convenient synthesis, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

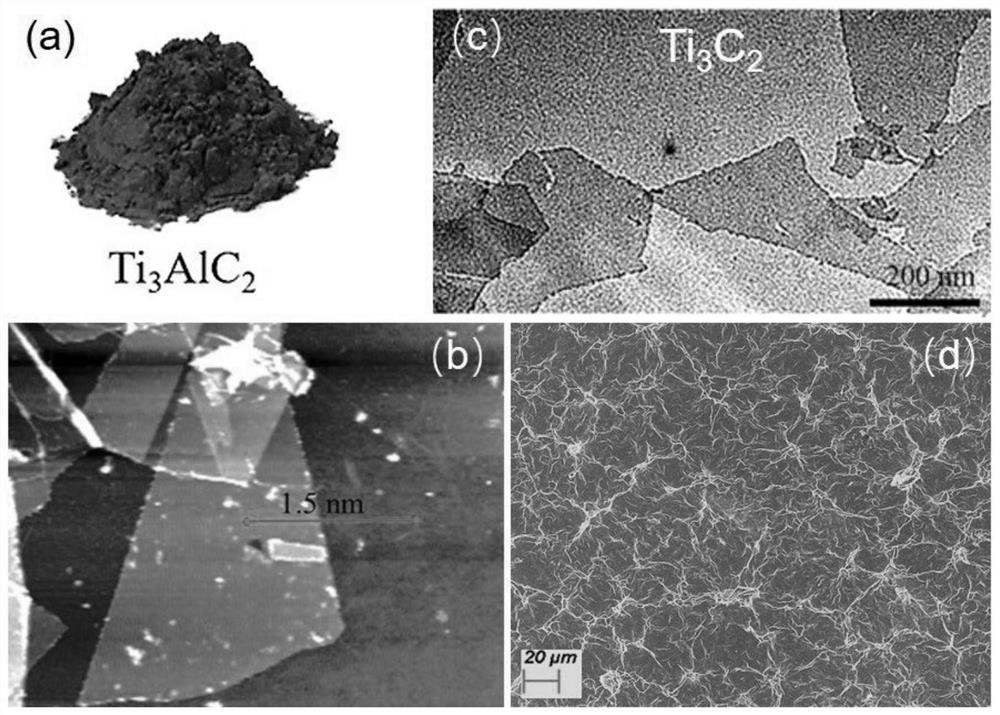

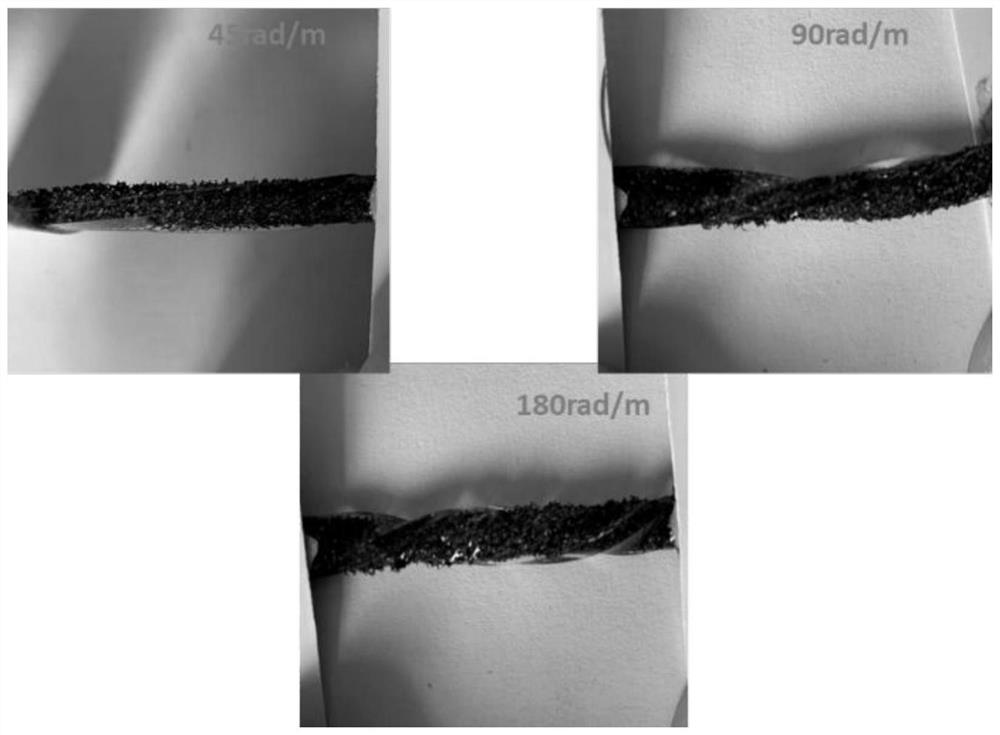

[0025] A fibrous Ti 3 C 2 MXene-based torsional angle sensors, including Ti 3 C 2 / porous fiber composite, Ti 3 C 2 / The two ends of the porous fiber composite are connected to the copper foil with conductive silver glue, and the flexible matrix is infiltrated inside; Ti 3 C 2 / porous fiber composites including Ti 3 C 2 Nanosheets and porous fibrous skeleton, Ti 3 C 2 The nanosheets are supported on the outer surface of the porous fiber skeleton.

[0026] A fibrous Ti 3 C 2 The preparation method of MXene-based torsional angle sensor specifically comprises the following steps:

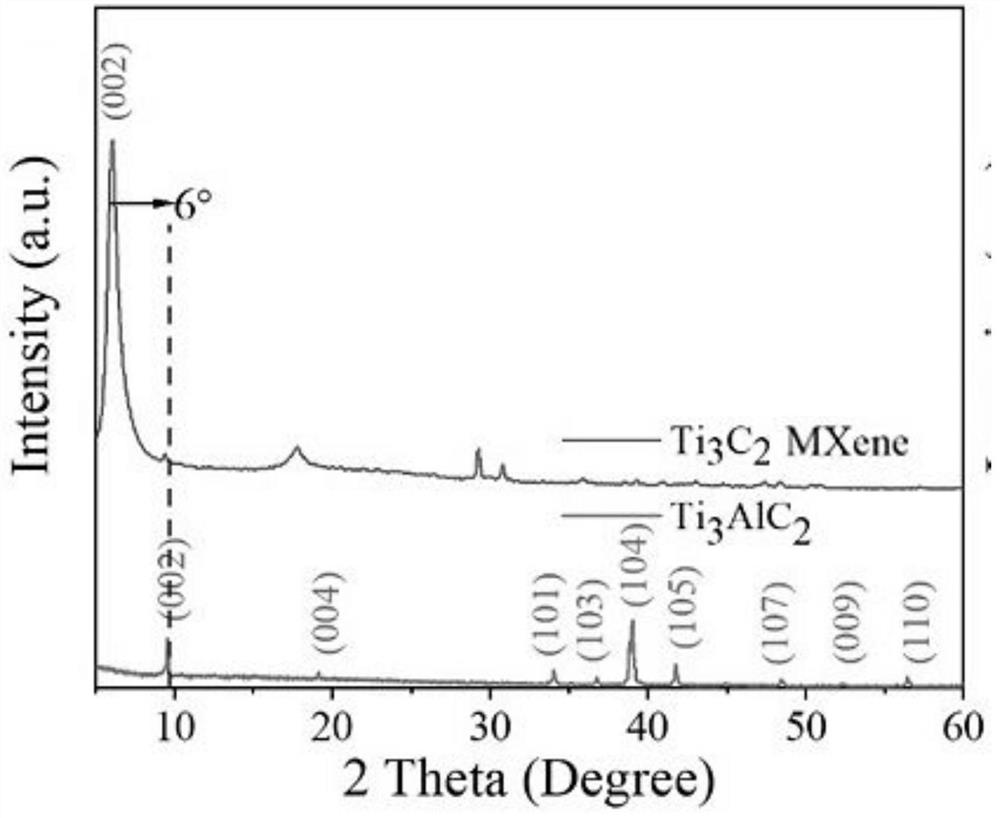

[0027] Add 5ml of deionized water to a mixture of 15ml of concentrated hydrochloric acid (HCl) and hydrofluoric acid (HF) to dilute it into a 9mol / L acid solution, then slowly add 1g of LiF to 20ml of the acid solution, and keep stirring Until LiF is completely dissolved; then, 1g Ti 3 AlC 2 The powder was slowly added to the above solution several times, and finally stirred and re...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is:

[0032] A fibrous Ti 3 C 2 The preparation method of MXene-based torsional angle sensor specifically comprises the following steps:

[0033] Add 5ml of deionized water to 15ml of hydrofluoric acid (HF) to make it diluted to 9mol / L acid solution, then slowly add 1g LiF to 20ml of acid solution, and keep stirring until LiF is completely dissolved; then, 1g Ti 3 AlC 2 The powder was slowly added to the above solution several times, and finally stirred and reacted at a constant temperature of 35°C for 24h to complete the conversion of Ti 3 AlC 2 Etching of Al element in the medium; transfer the etched mixture evenly to two 50ml centrifuge tubes, add deionized water to increase the volume of the mixture to 40ml, and then centrifuge at 5000rpm for 6min to remove the above For impurities in the supernatant, repeat the centrifugal treatment about 5 times until the pH of the supernatant is neutral; then add deio...

Embodiment 3

[0037] The difference between this embodiment and embodiment 1, 2 is:

[0038] A fibrous Ti 3 C 2 The preparation method of MXene-based torsional angle sensor specifically comprises the following steps:

[0039] Add 5ml of deionized water to a mixture of 15ml of concentrated hydrochloric acid (HCl) and hydrofluoric acid (HF) to dilute it into a 9mol / L acid solution, then slowly add 1g of LiF to 20ml of the acid solution, and keep stirring Until LiF is completely dissolved; then, 1g Ti 3 AlC 2 The powder was slowly added to the above solution several times, and finally stirred and reacted at a constant temperature of 35°C for 24h to complete the conversion of Ti 3 AlC 2 Etching of Al element in the medium; transfer the etched mixture evenly to two 50ml centrifuge tubes, add deionized water to increase the volume of the mixture to 40ml, and then centrifuge at 5000rpm for 6min to remove the above For impurities in the supernatant, repeat the centrifugal treatment about 5 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com