A composite piezoelectric catalyst and its preparation and application

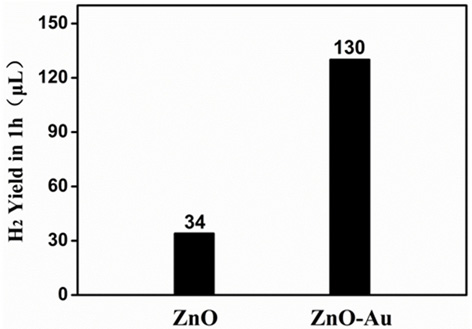

A catalyst and a composite technology, which are applied to composite piezoelectric catalysts and their preparation and application in the field of acoustic catalytic splitting of water for hydrogen production, can solve the problem of single piezoelectric semiconductors, the hydrogen production efficiency needs to be improved, and the mechanical energy-hydrogen can not be satisfied. Can transfer technology development needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Alcothermal Synthesis of ZnO Nanorods with Excellent Piezoelectric Properties

[0025] Weigh 0.330 g of (C 4 h 6 NO 4 ) 2 Zn (1 mmol) and 0.56 g of KOH (10 mmol) were dissolved in 10 mL and 20 mL of n-propanol, respectively; then the two reactant alcohol solutions were slowly mixed and stirred for 30 min to make the precursors evenly mixed After that, the reaction kettle was covered and sealed, put into a stainless steel sleeve and locked, placed in a programmed temperature-raising blast oven, and raised from room temperature to 150 °C over 60 minutes, and naturally dropped to room temperature after 24 hours of heat preservation; the obtained precipitation was deionized with After washing with water for 6 times until the ion concentration of the mother solution dropped below 10 ppm, it was then transferred to a vacuum oven at 60 °C for 24 h to obtain a white powder, namely ZnO nanorods with excellent piezoelectric properties.

Embodiment 2

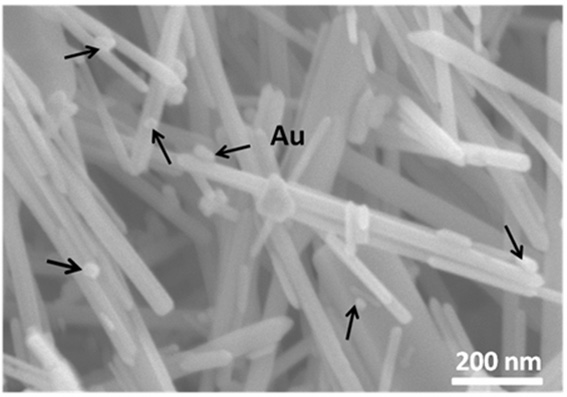

[0026] Example 2 Synthesis of ZnO-Au Composite Piezoelectric Catalyst by Defect Reduction Method

[0027] Weigh 50 mg of the zinc oxide nanorods obtained in Example 1, and disperse it in 50 mL of deionized water, then add 2.5 mL of 0.02 g / mL HAuCl 4 4H 2 O, and stirred for 4 h under dark conditions, the oxygen vacancy defects on the surface of ZnO were used to reduce gold ions to simple gold, which was loaded on the surface of nanorods. After the reduction, the sample was washed 4 times with deionized water until the ion concentration of the mother solution dropped below 10 ppm, and then transferred to a vacuum oven at 60 °C for 24 h to obtain a purple powder, which is the ZnO-Au composite piezoelectric catalyst.

Embodiment 3

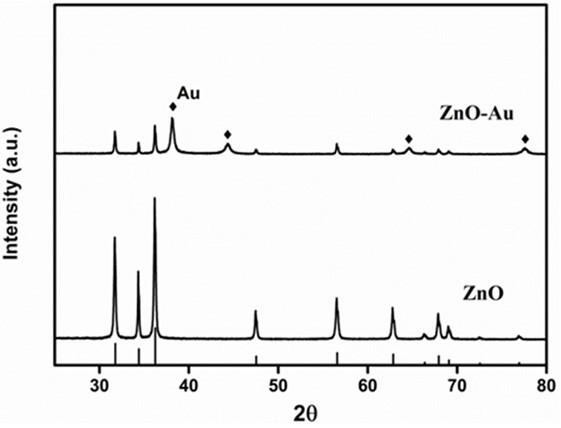

[0028] Example 3 Structural Characterization

[0029] The sample that embodiment 1, 2 is made is scanned by X-ray diffractometer, and the results are shown in figure 1 . Depend on figure 1 It can be determined that the obtained samples are hexagonal wurtzite crystal ZnO and ZnO-Au composites, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com