Lignin/graphene-based composite anticorrosive coating and preparation method and application thereof

An anti-corrosion coating, graphene-based technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of graphene sheets being easy to gather together, difficult to disperse, and limit applications, etc., to achieve both thermal stability Sexuality, low cost, and the effect of delaying the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This example provides a method for preparing a lignin / graphene-based composite anticorrosion coating.

[0066] (1) Purify and dry the alkali lignin, dissolve it in N,N-dimethylformamide (DMF) to obtain a lignin solution with a concentration of 0.25g / mL, according to the mass ratio of alkali lignin: hydrobromic acid solution =1:5 ratio Mix lignin solution and hydrobromic acid solution (48wt.%), stir at 120°C for 20h, after the reaction is complete, cool to room temperature, dropwise add to 2mol / L HCL solution to precipitate, Centrifuge at 8000 rpm for 30 min to obtain a precipitate, which is washed with water and ether to obtain hydroxylated lignin.

[0067] (2) Dissolving the hydroxylated lignin in water to obtain a lignin dispersion with a solubility of 0.5g / L, adding 1 mass part of natural graphite flakes to 25 mass parts of the lignin dispersion, at 15°C Use an ultrasonic cleaner to sonicate in an ice bath at 20KHz for 6 hours, centrifuge to remove unstable graphite...

Embodiment 2

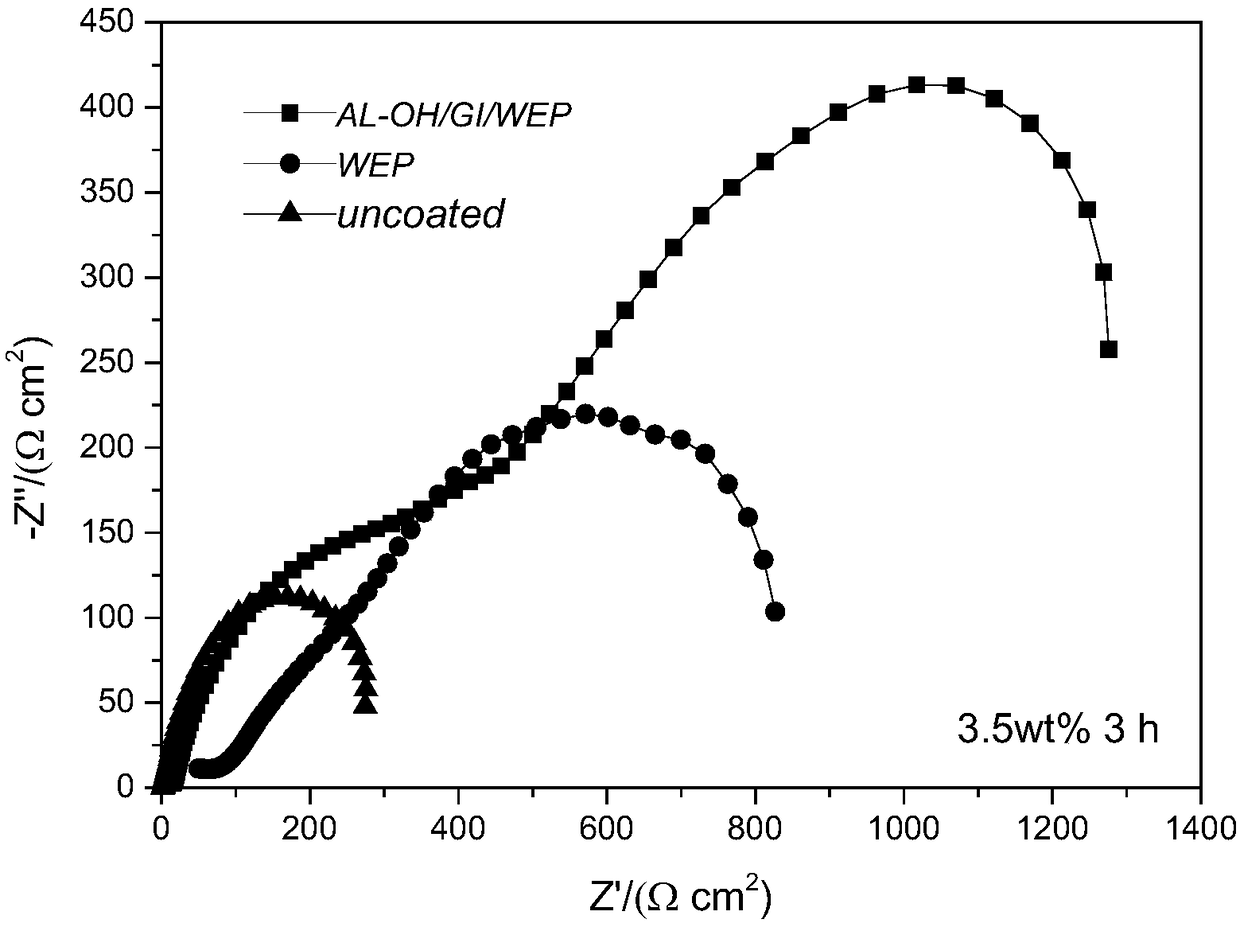

[0071] This example provides the application of the lignin / graphene-based composite anticorrosion coating prepared in Example 1 and its comparative example.

[0072] (1) Preparation of waterborne epoxy coating (WEP):

[0073] Mix 2.25 parts by mass of water-based curing agent PLR 736, 1 part by mass of isopropanol and 5 parts by mass of epoxy resin at room temperature with mechanical stirring, ultrasonically disperse at 20KHz for 10min in an ultrasonic cleaner, and place in a vacuum oven under ice bath conditions Next, vacuum out the air bubbles; after the air bubbles are completely removed, use a spin coater to coat a 2mm thick coating on Q235 carbon steel. Curing at room temperature for 5 hours to obtain a waterborne epoxy coating.

[0074] (2) Preparation of graphene waterborne epoxy coating (G / WEP):

[0075] Add natural graphite flakes into water, use an ultrasonic cleaning machine at 15°C to ultrasonicate at 20KHz for 6 hours, and centrifuge to remove unstable graphite ...

Embodiment 3

[0079] This example provides a method for preparing a lignin / graphene-based composite anticorrosion coating.

[0080] (1) Sodium lignosulfonate is purified and dried, dissolved in N,N-dimethylformamide (DMF) to obtain a lignin solution with a concentration of 0.2g / mL, according to the mass ratio of sodium lignosulfonate: Hydrobromic acid solution=1:5 ratio Mix lignin solution and hydrobromic acid solution (48wt.%), stir at 150°C for 20h, after the reaction is completed, cool to room temperature, add dropwise to 2mol / L HCL Precipitate in the solution, centrifuge at 8000 rpm for 30 min to obtain a precipitate, wash with water and ether to obtain hydroxylated lignin.

[0081] (2) Dissolving the hydroxylated lignin in water to obtain a lignin dispersion with a solubility of 0.5g / L, adding 1 mass part of natural graphite flakes to 25 mass parts of the lignin dispersion, at 15°C Use an ultrasonic cleaner to sonicate in an ice bath at 20KHz for 6 hours, centrifuge to remove unstable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com