Low-smoke low-halogen flame-retardant conveyor belt covering glue for coal mine and preparation process thereof

A technology for covering rubber and conveyor belts, applied in conveyors, transportation and packaging, etc., can solve a large number of irritating smoke and harmful substances, and achieve good UV resistance, excellent flame retardancy, and good light resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

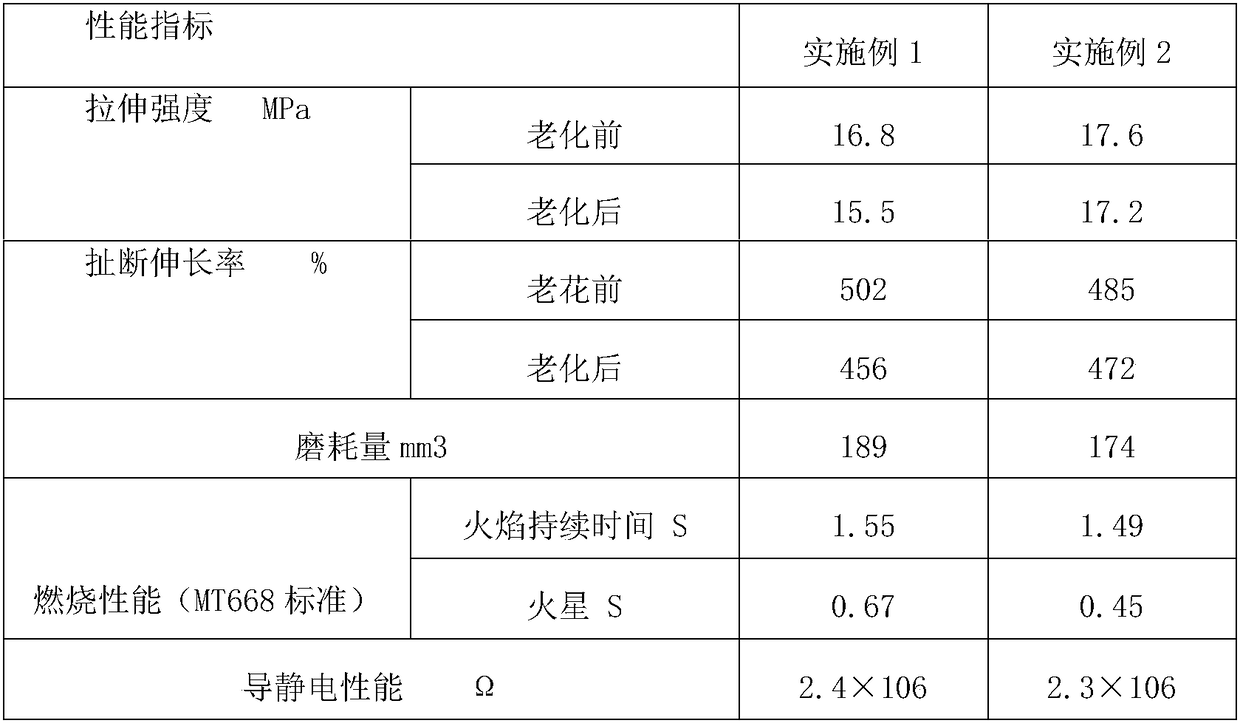

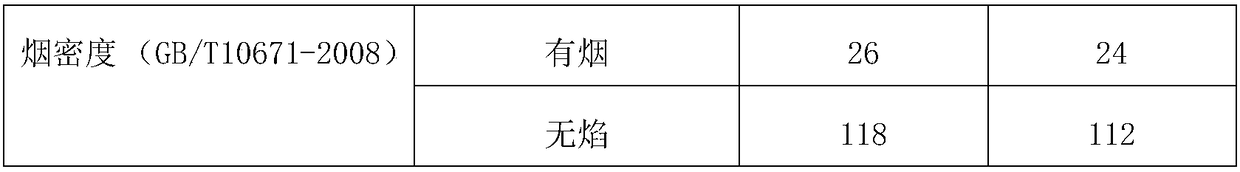

Examples

Embodiment 1

[0021] Example 1: A low-smoke, low-halogen, flame-retardant conveyor belt covering rubber for coal mines. The chemical composition and mass percentage of the covering rubber are as follows: natural standard rubber: 0-50 parts, styrene-butadiene rubber SBR1502: 20-80 parts, Butadiene BR9000 rubber: 0-40 parts, polyisobutylene PB1300: 0-10 parts, anti-aging agent: 3-6 parts, zinc oxide: 4-8 parts, magnesium oxide: 0-3 parts, stearic acid: 0-2 parts Parts, flow release agent: 1-3 parts, N234 carbon black: 30-50 parts, nano aluminum hydroxide: 10-20 parts, antimony trioxide: 4-8 parts, decabromodiphenylethane: 5- 15 parts, composite ceramic powder: 5-20 parts, intumescent halogen-free flame retardant IFR: 5-15 parts, multi-purpose synergistic halogen-free flame retardant PNA220: 5-15 parts, smoke suppressant molybdenum salt: 2 -8 parts, Accelerator: 0-7 parts, Sulfur: 0-3 parts.

[0022] The chemical composition and content of the cover rubber in this embodiment are selected as f...

Embodiment 2

[0029] Example 2: A low-smoke, low-halogen, flame-retardant conveyor belt covering rubber for coal mines. The chemical composition and content of the covering rubber are selected as follows: styrene-butadiene rubber SBR1502: 70kg, butadiene-butadiene BR9000 rubber: 30kg, polyisobutylene PB1300: 10kg, Antiaging agent: 3kg, zinc oxide: 6kg, magnesium oxide: 1kg, stearic acid: 1kg, flow release agent: 1kg, N234 carbon black: 40kg, nano aluminum hydroxide: 15kg, antimony trioxide: 6kg, decabromine Diphenylethane: 15kg, composite ceramic powder: 10kg, intumescent halogen-free flame retardant IFR: 10kg, multi-purpose synergistic halogen-free flame retardant PNA220: 13kg, smoke suppressant molybdenum salt: 5kg, accelerator: 3.2 kg, sulfur: 3kg.

[0030] Wherein, the smoke suppressant molybdenum salt is a mixture of molybdenum trioxide and ammonium octamolybdate, and the anti-aging agent is a mixture of anti-aging agent RD, anti-aging agent 4010NA, and anti-aging agent 4020, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com