Production method for generating isooctene by utilizing acetic acid and mixed C4 and producing high-purity isooctane by hydrogenating

A manufacturing method and technology of isooctene, which is applied in the preparation of organic compounds, hydrogenation of hydrocarbons, preparation of carboxylic acid esters, etc., can solve the problem of inability to obtain high-purity isooctene and isobutane, difficult separation of production products, and environmental protection Prominent problems and other problems, to achieve the effect of improving the ability to resist risks, high octane number, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

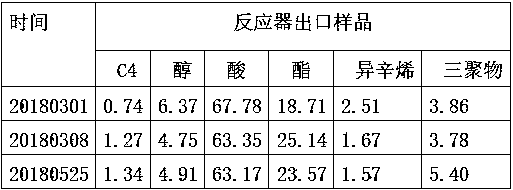

Embodiment 1

[0042] At present, there is a relatively advanced synthetic production of tert-butyl acetate in China (Yueyang Fuhe Technology Co., Ltd.), which uses acetic acid and high-purity isobutene to be mixed in a certain proportion and the recycled material of the system is combined into pretreatment feed, which enters the pretreatment reaction through a flow meter. After removing metal ions, it enters the first-stage esterification reactor and the second-stage esterification reactor in series, and the reacted material enters the stripping tower, and the unreacted isobutene with a low boiling point is re- The steam from the boiler steams into the top of the tower, enters the stripper condenser to condense, and then enters compression to recover isobutene. The material at the bottom of the stripper is measured by a flow meter and then pumped to the deacidification tower. It mainly produces tert-butyl acetate products, in which the isooctene produced by by-products is separated, and the ...

Embodiment 2

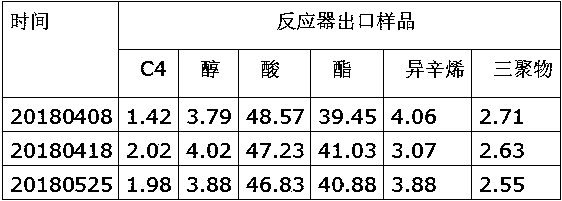

[0046] In the process of implementation, we adopt the synthetic reaction of mixed C4 and glacial acetic acid to generate crude ester, which further reduces the production cost. The macroporous cationic resin catalyst is added into the reactor tube, and then a certain amount of glacial acetic acid is added into the reaction system to establish a cycle. Control the speed and add mixed C4 evenly. The molar ratio of acid to ene is 1:7. The reaction temperature is 28°C and the reaction pressure is 0.8MPa. After 2.5 hours of reaction, take a sample for analysis. The yield of tert-butyl acetate is about 40%. , selectivity 95.36%. An example by mass percentage is shown in Table 2 below.

[0047] Table 2

[0048]

Embodiment 3

[0050] Mix the material after C4 synthesis with the tert-butyl acetate from the post-distillation section, and the ester (content about 80-90%) is transferred to a reactor equipped with the same type of catalyst to establish a cycle, and the reaction temperature is 55°C , the reaction pressure is 0.8MPa, and after 2.5h of reaction, sampling is carried out for analysis. The yield of isooctene is about 40%, and the selectivity is 85.48%. The following table 3 is given as an example by mass percentage.

[0051] table 3

[0052] Time 2018

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com