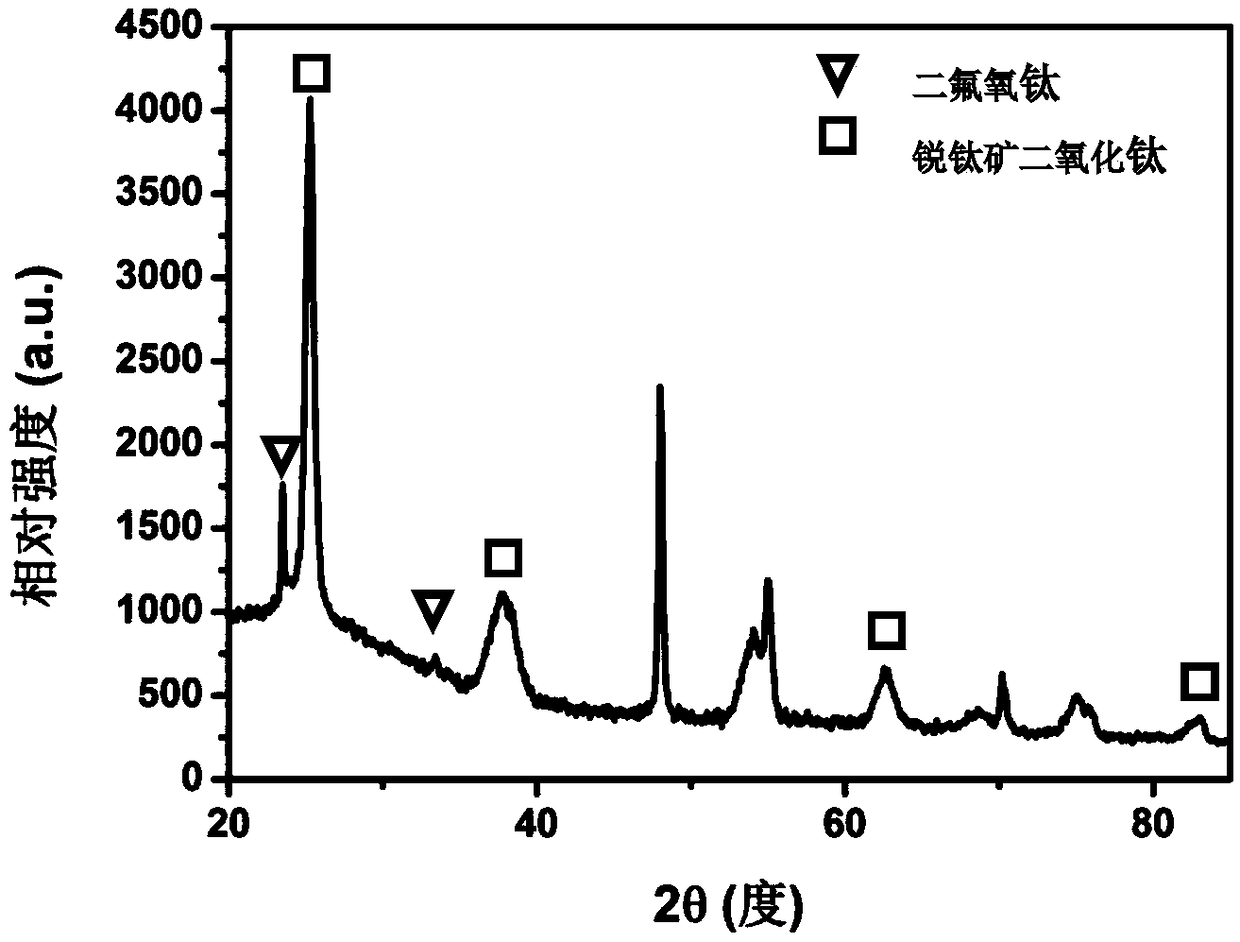

Preparation method of titanium dioxide/titanium oxydifluoride composite gas-phase photocatalyst

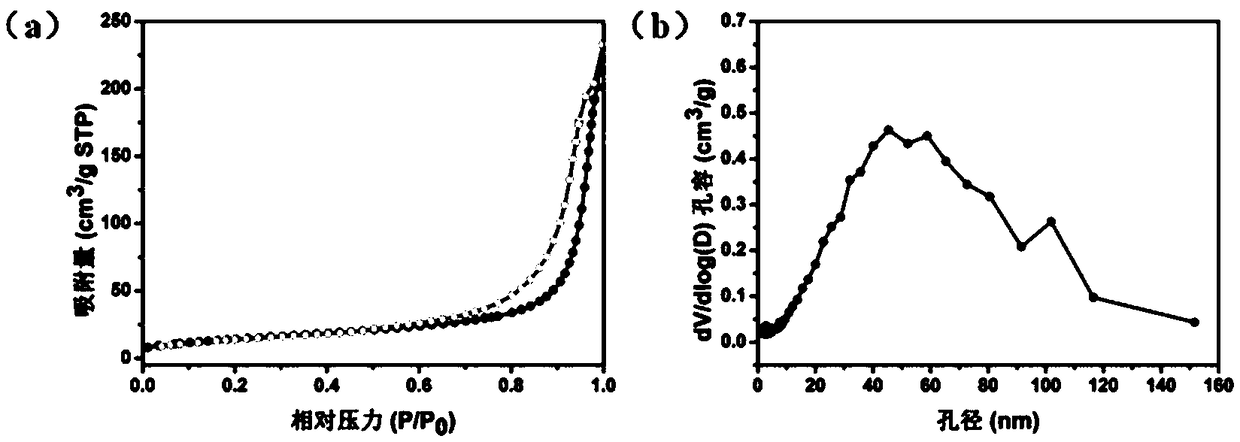

A technology of titanyl difluoride and titanium dioxide, which is applied in the field of synthesis of photocatalytic materials, can solve problems such as complex preparation methods, and achieve the effects of simple synthesis methods, enriched pore structure, and reduced recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 4mL of toluene and pour it into a polytetrafluoroethylene reactor, add 2mL of hydrofluoric acid to it, and stir at a constant speed of 1500r / min for 10min.

[0035] (2) After 10 minutes, add 25 mL of tetrabutyl titanate to the solution obtained in (1), and stir uniformly at 1500 r / min for 20 minutes.

[0036] (3) After the stirring is completed, take out the magnets in the reaction kettle, encapsulate the reaction kettle, and put it in a blast drying box, set the temperature to 180°C, and keep the reaction for 24 hours.

[0037] (4) Take out the reaction kettle from the blast drying box, remove the liquid by centrifugation, and obtain a blue solid product. Clean the product with absolute ethanol. Centrifuge the product at 8000r / min for 10min. Repeat this step to clean the product three times. Put it in an oven at 40°C and dry it to obtain the titanium dioxide / titanium oxyfluoride composite gas-phase photocatalyst.

[0038] (5) Disperse 10 mg of the above product in 2 m...

Embodiment 2

[0044] (1) Take 4mL of toluene and pour it into a polytetrafluoroethylene reactor, add 2mL of hydrofluoric acid to it, and stir at a constant speed of 1500r / min for 10min.

[0045] (2) After 10 minutes, add 25 mL of tetrabutyl titanate to the solution obtained in (1), and stir uniformly at 1000 r / min for 20 minutes.

[0046] (3) After the stirring is completed, take out the magnets from the reaction kettle, encapsulate the reaction kettle, and put it in a blast drying oven, set the temperature to 200° C., and keep it warm for 6 hours.

[0047] (4) Take out the reaction kettle from the blast drying box, remove the liquid by centrifugation, and obtain a blue solid product. Clean the product with absolute ethanol. Centrifuge the product at 8000r / min for 10min. Repeat this step to clean the product three times. Put it in an oven at 40°C and dry it to obtain the titanium dioxide / titanium oxyfluoride composite gas-phase photocatalyst.

[0048] (5) Disperse 10 mg of the above product in 2 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com