Amino silane grafted and modified sepiolite adsorbent and preparation method and application thereof

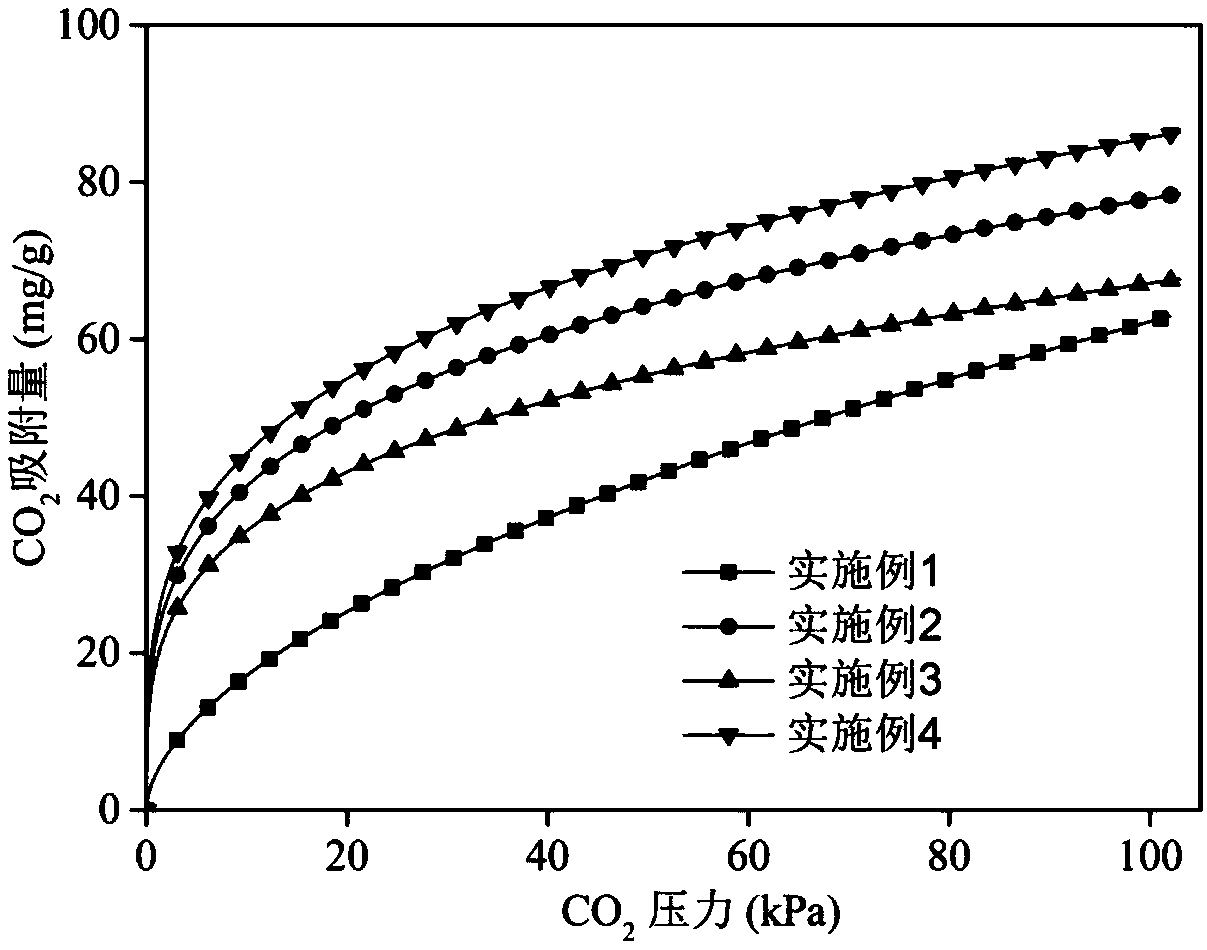

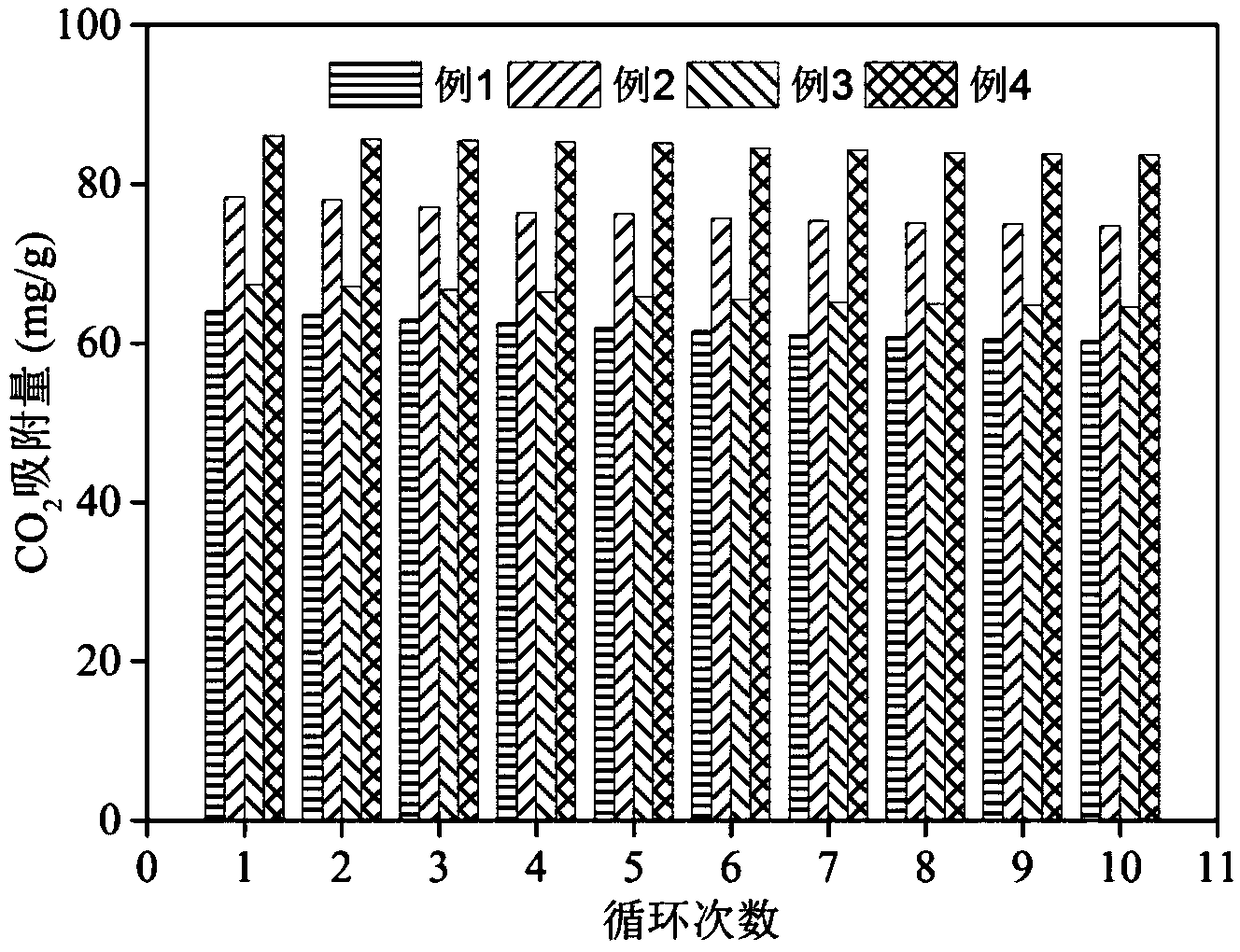

A technology of aminosilane and sepiolite, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of inability to meet the requirements of carbon dioxide capture, high cost of carbon dioxide capture, poor carbon dioxide adsorption effect, etc., and achieve cyclic adsorption Excellent performance, outstanding cycle regeneration adsorption performance, simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing a sepiolite adsorbent modified by aminosilane grafting, comprising the following steps:

[0026] (1) Pretreatment: Add the industrial sepiolite powder into the hydrochloric acid solution with a concentration of 2mol / L, the solid-liquid ratio is 1:30, and after stirring continuously at room temperature for 15 hours, the solid-liquid separation is carried out, and the filtrate is fully washed until the filtrate is neutral. After drying at 100°C for 12 hours, acid-treated sepiolite was obtained after grinding. Then activate the acid-treated sepiolite at a high temperature of 250° C. for 2 hours to obtain pretreated sepiolite.

[0027] (2) Aminosilane modification: add 6g of pretreated sepiolite to absolute ethanol, so that the solid-to-liquid mass ratio of sepiolite to absolute ethanol is 1:20, and stir evenly. The temperature of the above mixture was raised to 70°C, and 1.2 g of 3-aminopropyltrimethoxysilane (APTS) was slow...

Embodiment 2

[0029] This embodiment provides a method for preparing a sepiolite adsorbent modified by aminosilane grafting, comprising the following steps:

[0030] (1) Pretreatment: Add the industrial sepiolite powder into the hydrochloric acid solution with a concentration of 2mol / L, the solid-liquid ratio is 1:30, and after stirring continuously at room temperature for 15 hours, the solid-liquid separation is carried out, and the filtrate is fully washed until the filtrate is neutral. Dry at 100°C for 12 hours, fully grind and activate at 250°C for 2 hours to obtain pretreated sepiolite.

[0031] (2) Aminosilane modification: add 6 g of pretreated sepiolite to absolute ethanol, so that the solid-to-liquid mass ratio of sepiolite to absolute ethanol is 1:30, and stir evenly. The temperature of the above mixture was raised to 80°C, and 1.2 g of 3-aminopropyltriethoxysilane (APTES) was slowly added, so that the mass ratio of APTES to sepiolite was 1:5, and the reaction was kept under reflu...

Embodiment 3

[0033] This embodiment provides a method for preparing a sepiolite adsorbent modified by aminosilane grafting, comprising the following steps:

[0034] (1) Pretreatment: Add the industrial sepiolite powder into the hydrochloric acid solution with a concentration of 2mol / L, the solid-liquid ratio is 1:30, and after stirring continuously at room temperature for 15 hours, the solid-liquid separation is carried out, and the filtrate is fully washed until the filtrate is neutral. Dry at 100°C for 12 hours, fully grind and activate at 250°C for 2 hours to obtain pretreated sepiolite.

[0035](2) Aminosilane modification: add 6 g of pretreated sepiolite to absolute ethanol, so that the solid-to-liquid mass ratio of sepiolite to absolute ethanol is 1:30, and stir evenly. Raise the temperature of the above mixture to 80°C, slowly add 1.2g of 2-aminoethyl-3-aminopropyltrimethoxysilane (AEAPTS), so that the mass ratio of AEAPTS to sepiolite is 1:5, and keep the reflux reaction for 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com