High-energy density battery negative electrode tab and fabrication method thereof

A technology with high energy density and production method, which is applied in the field of high-polymer lithium-ion power batteries, can solve the problems of weak welding and difficult welding, and achieve the effects of firm and reliable welding, stable laser welding, and consistent metal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

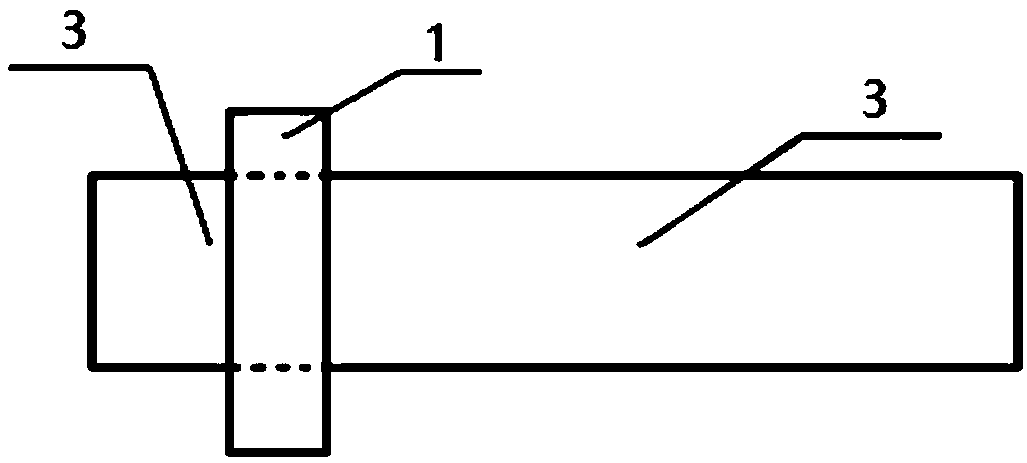

[0037] A high-energy-density battery negative tab, which sequentially includes a copper nickel-plated metal tab 3, a welding lap area 5, and an aluminum metal tab 4 for transfer, and a PP polymer is fixed on the copper nickel-plated tab 3 Propylene modified resin 1. like figure 2 shown. image 3 Schematic diagram of the cross-section of the welding overlap area, in image 3 Medium 6 laser welding melting point.

[0038] The manufacturing method of the above-mentioned negative electrode tab comprises the following steps:

[0039] 1) According to the width of the nickel-plated copper lug, select the aluminum material with the same width and cut it to the required length, and use the ZL-A metal sheet material fixed-length cutting machine to complete it;

[0040] 2) Position the nickel-plated copper lug with PP polypropylene modified resin on the mold, position the aluminum metal sheet on the nickel-plated copper, and overlap the aluminum metal sheet and the nickel-plated cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com