A sensor integrating oxygen concentration and ultraviolet intensity detection functions and its detection method

A technology for intensity detection and oxygen concentration, which is applied in the field of sensors, can solve the problems of increased complexity and instability, single structure of multi-functional sensors, combustion or explosion, etc., to achieve environmental friendliness, avoid adverse factors, and eliminate temperature the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

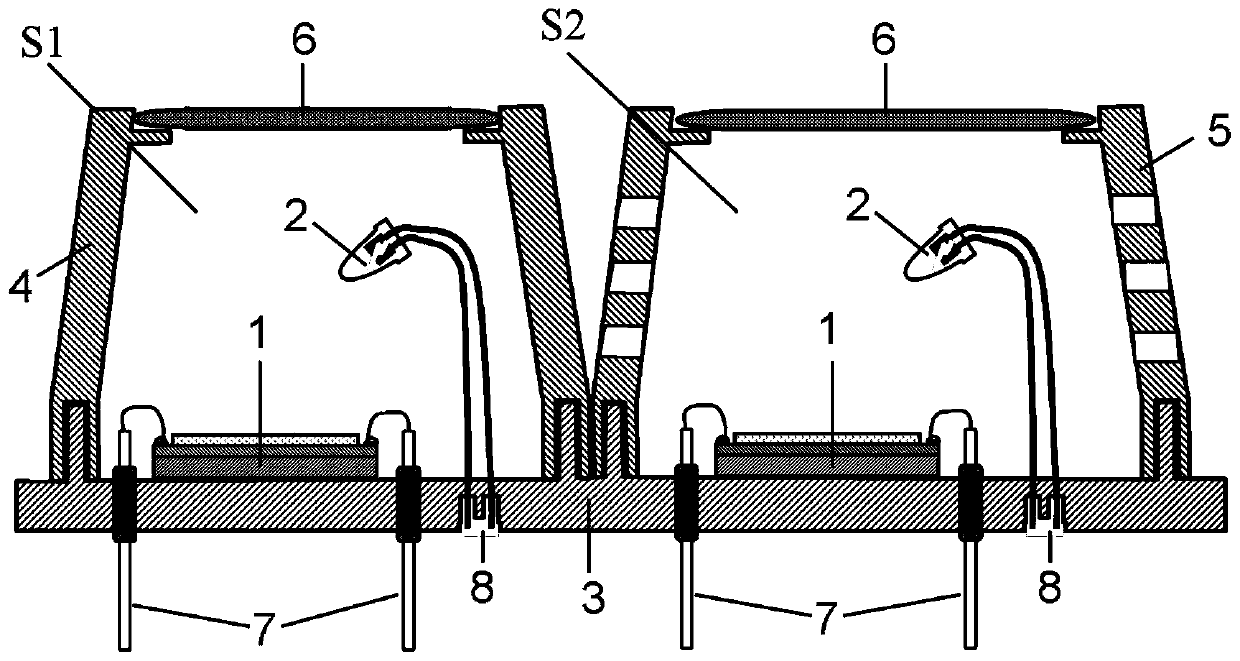

[0045] This embodiment provides a sensor that integrates oxygen concentration and ultraviolet intensity detection functions, such as figure 1 Shown is a schematic structural view of the sensor provided in this embodiment, the sensor includes an insulating base 3, and a first metal shell 4 and a second metal shell 5 installed on the insulating base 3; the first metal shell 4 and the second The metal shell 5 and the insulating base 3 form two mutually independent first chambers and second chambers; the first chamber is provided with a sensitive element 1 and an ultraviolet LED lamp 2, and the first chamber adopts a closed chamber The chamber constitutes the ultraviolet intensity detection unit S1, which is sealed with high-purity nitrogen in this embodiment; the second chamber is also provided with a sensitive element 1 and an ultraviolet LED lamp 2, and the second chamber is formed by a chamber communicating with the outside world to form an oxygen chamber. Concentration detect...

specific Embodiment approach

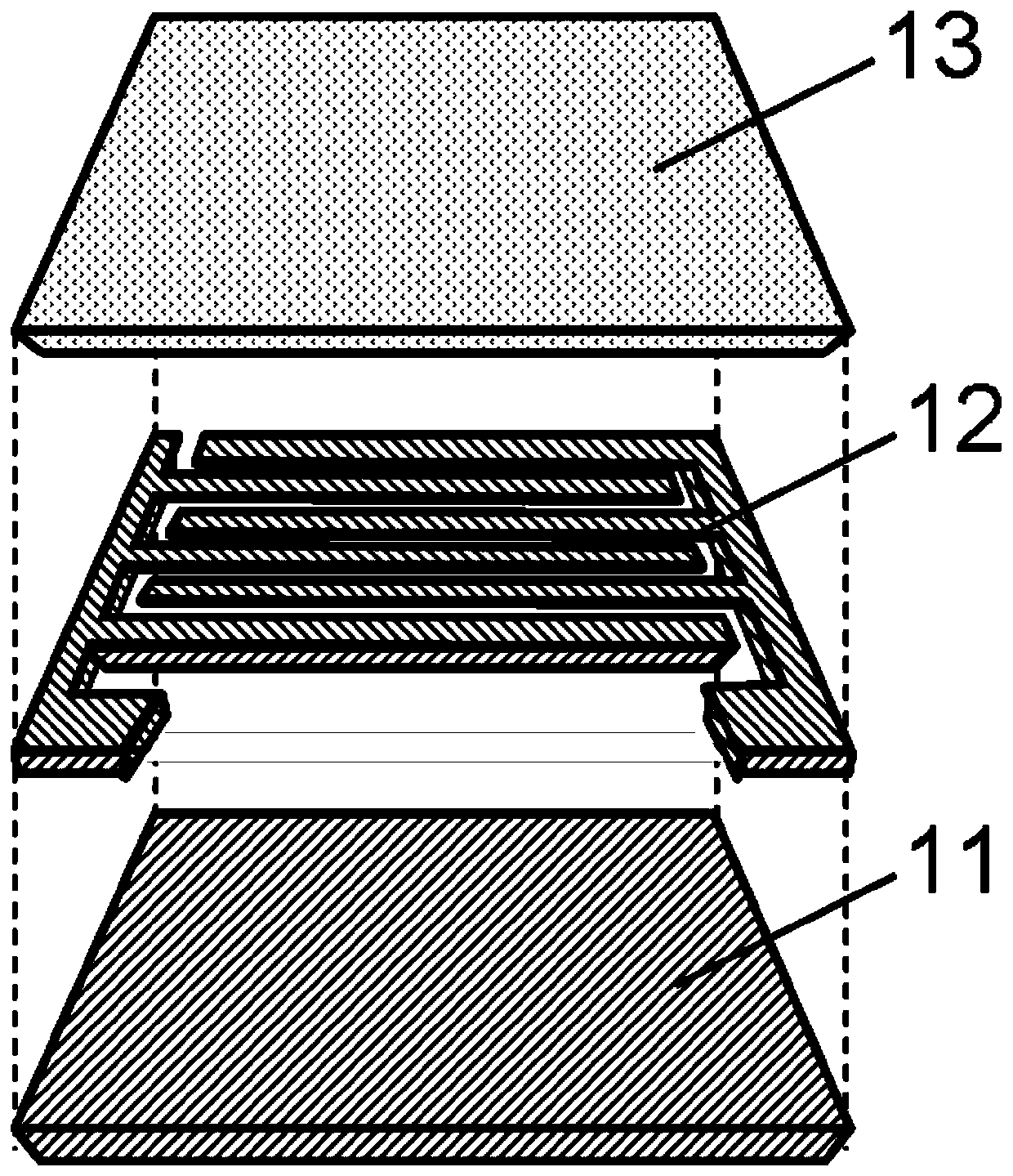

[0053] As a specific embodiment, the preparation of the zinc oxide (ZnO) nanoparticle film is preferably a spin-coating process, including the following steps:

[0054] Step A: Prepare nano-sized ZnO particles by chemical method;

[0055] Step B: dispersing the nano-sized ZnO particles in absolute ethanol to form a ZnO nano-particle dispersion, wherein the concentration of ZnO nanoparticles is 1-6 mg / ml; the ultrasonic power of the ultrasonic dispersion operation is 90 Hz, and the ultrasonic time is 2 hours ;

[0056] Step C: Apply the ZnO nanoparticle dispersion on the surface of the interdigitated electrode on the substrate by a spin coating process to form a ZnO nanoparticle wet film; the specific operation of the spin coating process is as follows: Treat for 5 seconds under the condition; then process for 20 seconds under the condition of high speed 3000r / min; repeat the above operation to complete 20 to 100 times of spin coating;

[0057] Step D: putting the sensitive e...

Embodiment 2

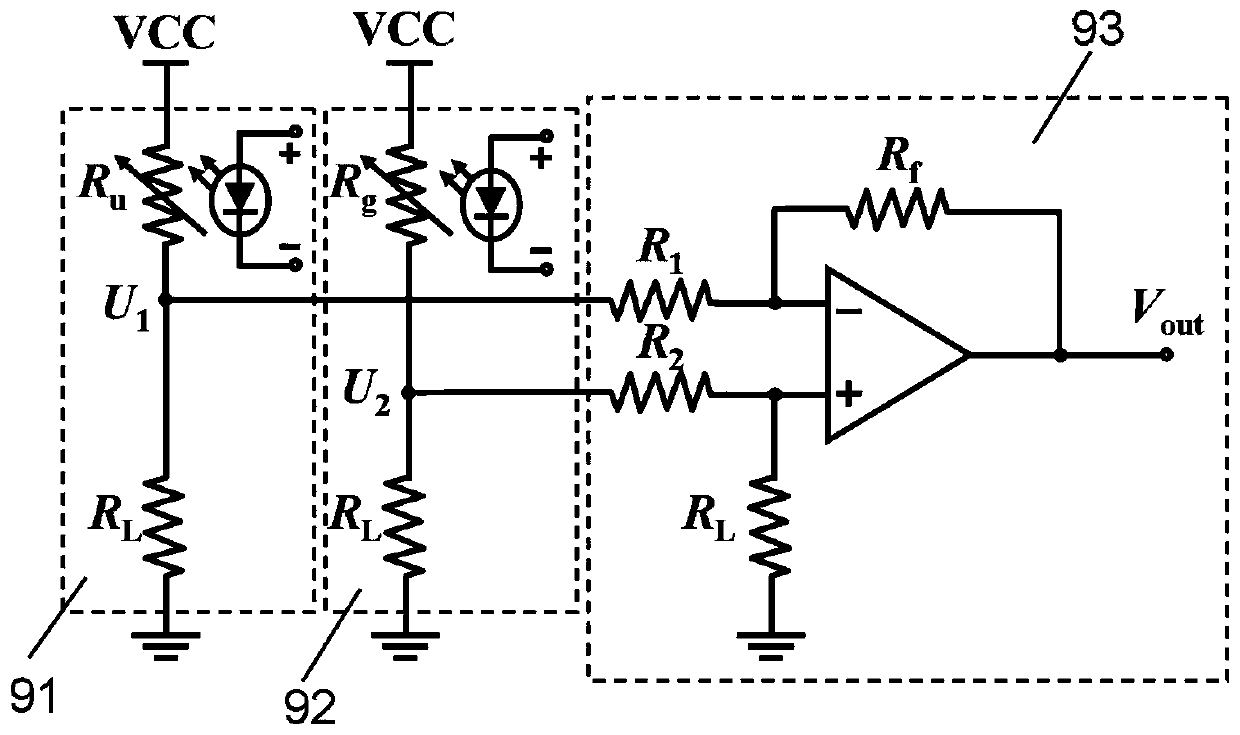

[0069] Photoelectric performance evaluation of sensitive element 1:

[0070] Adopt American Keithley 4200-SCS type semiconductor characteristic analysis system, the voltage scanning range-5-5V, record respectively the sensitive element 1 that is coated with ZnO nanoparticle film and grows with ZnO nanorod array thin film in the presence of 365nm ultraviolet light (radiation power 5.7mW / cm 2 ) Irradiated and without 365nm UV-irradiated I-V curve change relationship, see the results Figure 6 .

[0071] Depend on Figure 6 It can be seen that the above two sensitive thin films 13 are in ohmic contact with the gold interdigitated electrodes, and the corresponding sensitive elements show obvious ultraviolet light response. When there is no light, the currents of the sensitive elements coated with ZnO nanoparticle film and ZnO nanorod array film under 5V bias are 1.91×10 -8 A and 1.11×10 -4 A; When there is light, the photocurrents of the two under 5V bias are 2.63×10 -4 A an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com