System for generating medium-pressure high-temperature steam through printing and dyeing wastewater afterheat

A technology for printing and dyeing wastewater and high-temperature steam, applied in the field of high-temperature steam systems, can solve the problems of blockage of sewage sources, less installation of waste heat recovery, and low enthusiasm for heat energy recovery, so as to improve clogging and corrosion, reduce environmental pollution, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

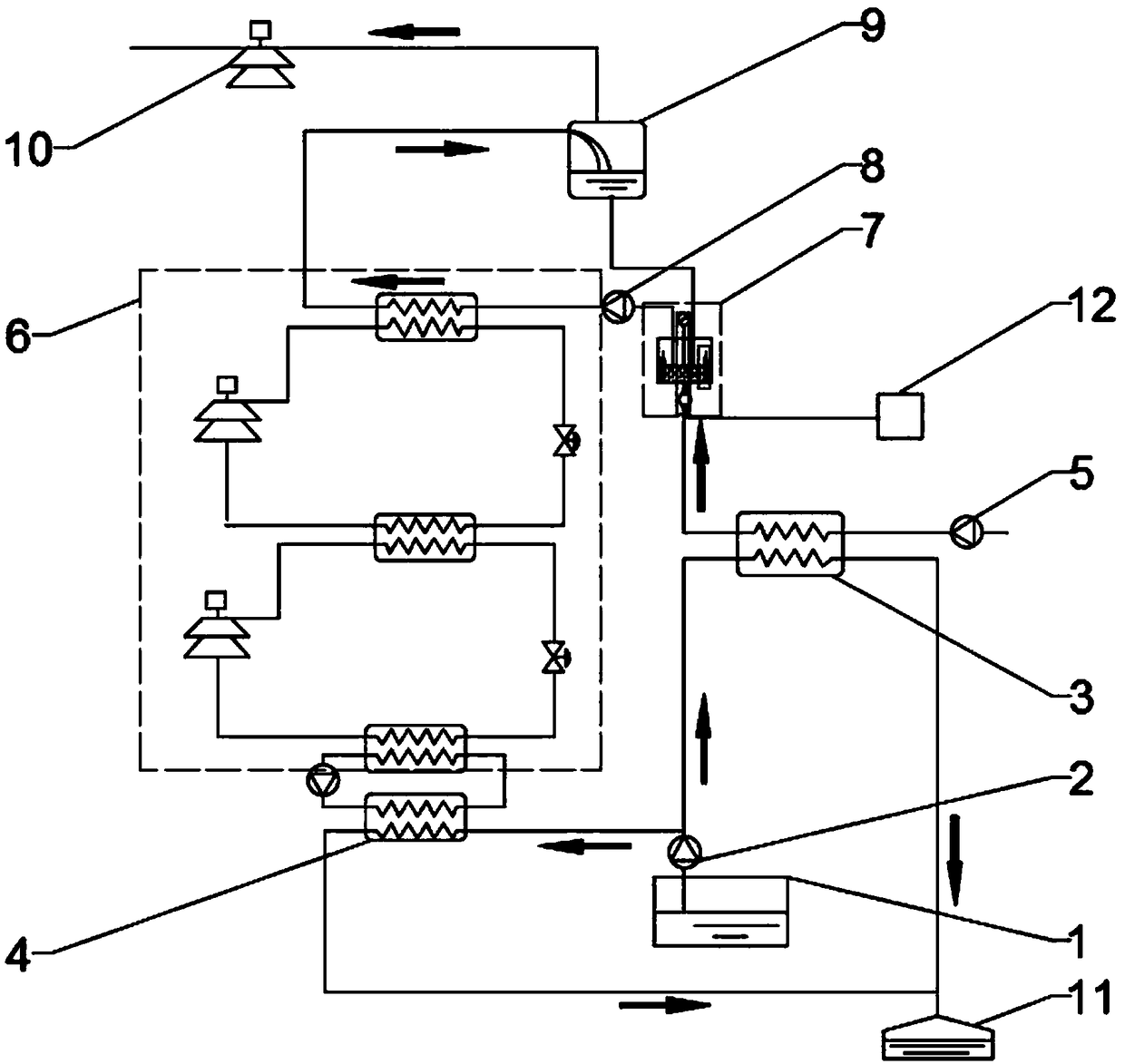

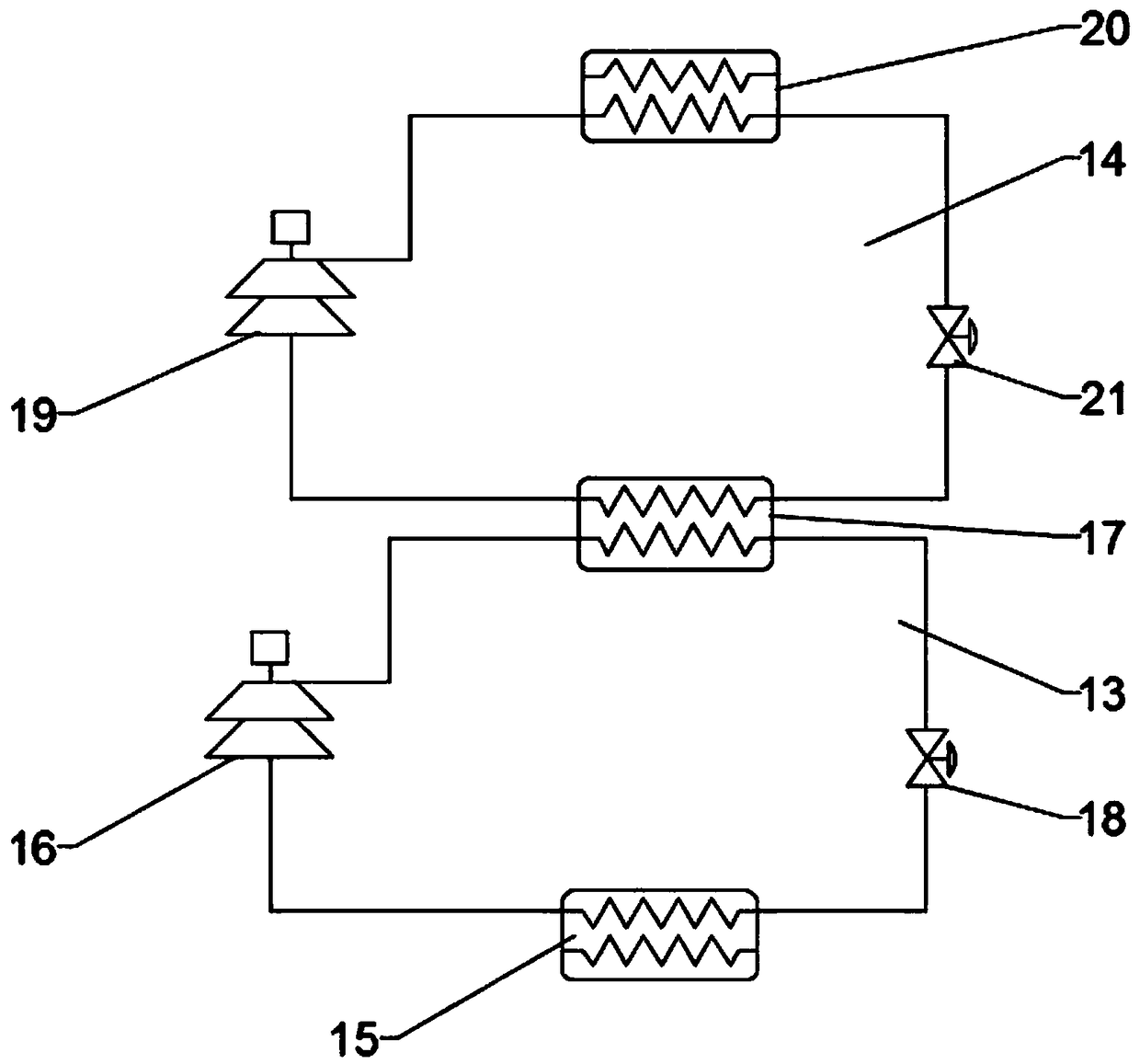

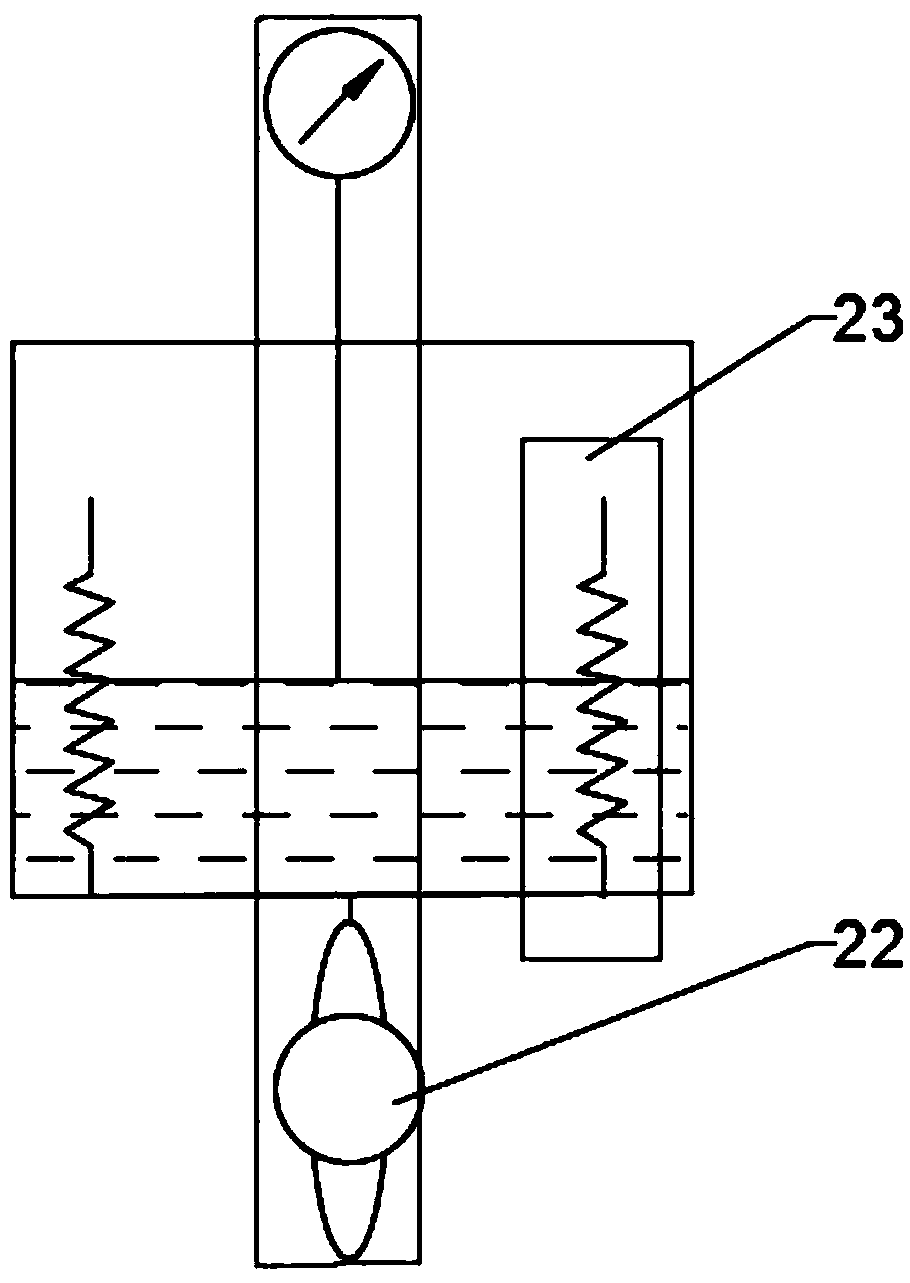

[0018] Such as figure 1 , using the residual heat of printing and dyeing wastewater to generate medium-pressure high-temperature steam system, the wastewater from the printing and dyeing wastewater pool 1 is divided into the first water flow and the second water flow through the anti-clogging centrifugal pump 2, and the first water flow enters the first shell-and-tube heat exchanger and The water input by the cold water delivery pump 5 performs heat exchange, and the cooled waste water after the exchange is discharged into the cooling sewage discharge pool 11, and the heated hot water after the exchange is mixed with the hot water 12 obtained from other processes and enters the high-temperature hot water recovery system 7. The hot water delivery pump 8 enters the high-temperature heat pump unit 14 of the cascade heat pump unit 6. After the second water flows through the second shell-and-tube heat exchanger 4 for heat exchange, the cooled waste water is discharged into the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com