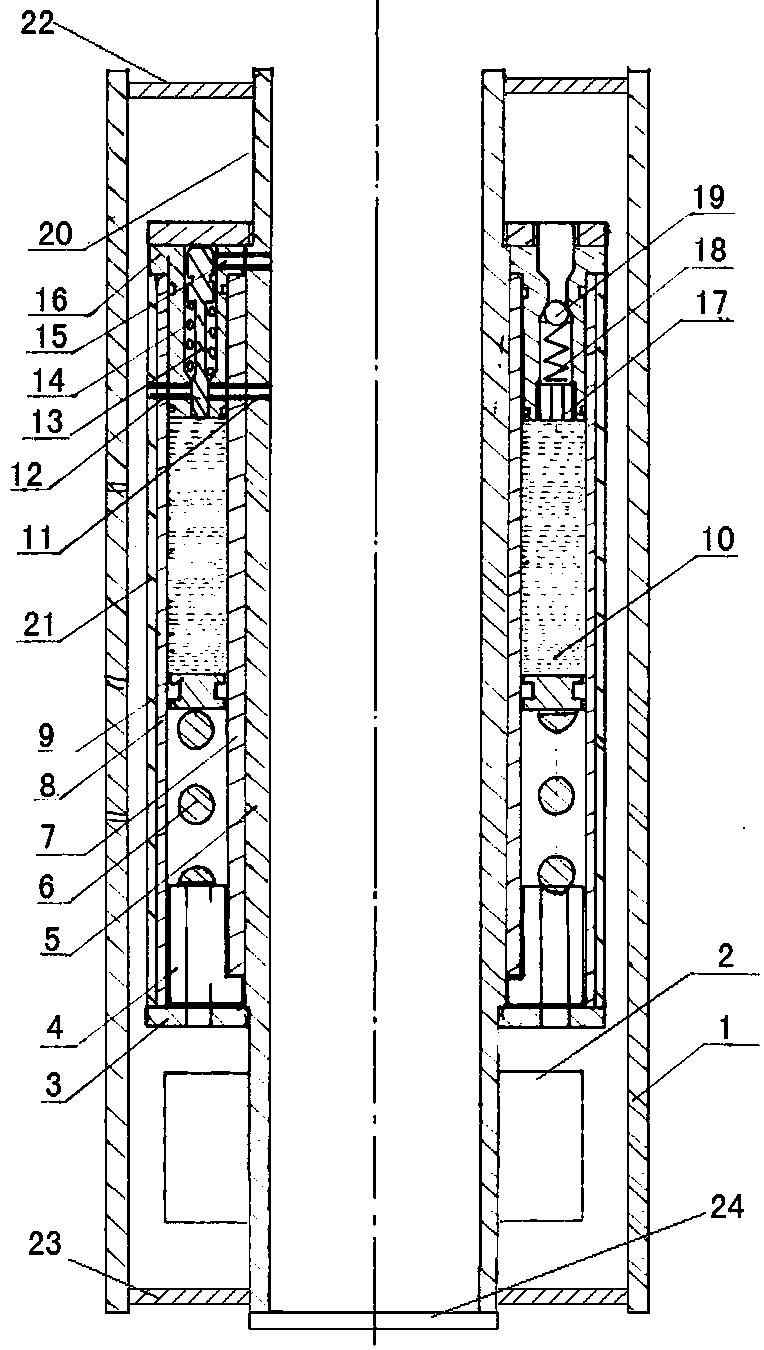

Using method of water injection well chemical scale inhibition and removing device

A technology for scale prevention, descaling, and water injection wells, which is used in earth-moving drilling, wellbore/well components, cleaning appliances, etc. It can solve the problems of short acidification validity period, increase oil refining costs, corrosion, etc., and avoid frequent well shutdown operations. , The effect of reducing operating costs and extending working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

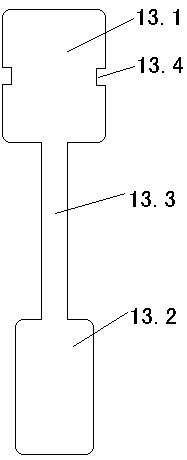

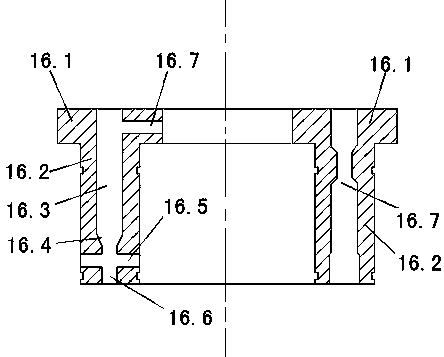

Examples

Embodiment 2

[0040] Embodiment 2, the difference between the present invention and Embodiment 1 is: in the container formed between the reservoir inner tube 7, the reservoir outer tube 8, the floating piston 9, and the container sealing cover 16 of the present invention, hydrogen chloride gas can also be injected , When in use, hydrogen chloride gas dissolves into the liquid, and similarly, it can also realize the chemical reaction to the scale at the faucet. The advantage of injecting hydrogen chloride gas is: when in use, hydrogen chloride gas is directly dissolved in water, and the concentration of the formed hydrochloric acid solution is higher, so that the reaction speed with the scale calcium carbonate is faster. Compared with the injection of concentrated hydrochloric acid, the concentration of hydrochloric acid acting on the scale is higher and the effect is better, but the injection of hydrogen chloride gas generally requires 2 MPa or more, which requires thicker protective sleeves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com