Production equipment for special pull nets for vine crops

A technology for production equipment and crops, applied in the field of crop growth aids, can solve the problems of low overall quality, heavy labor, unfriendly environment, etc., achieve high overall quality, alleviate crop quality, and reduce the use of pesticides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

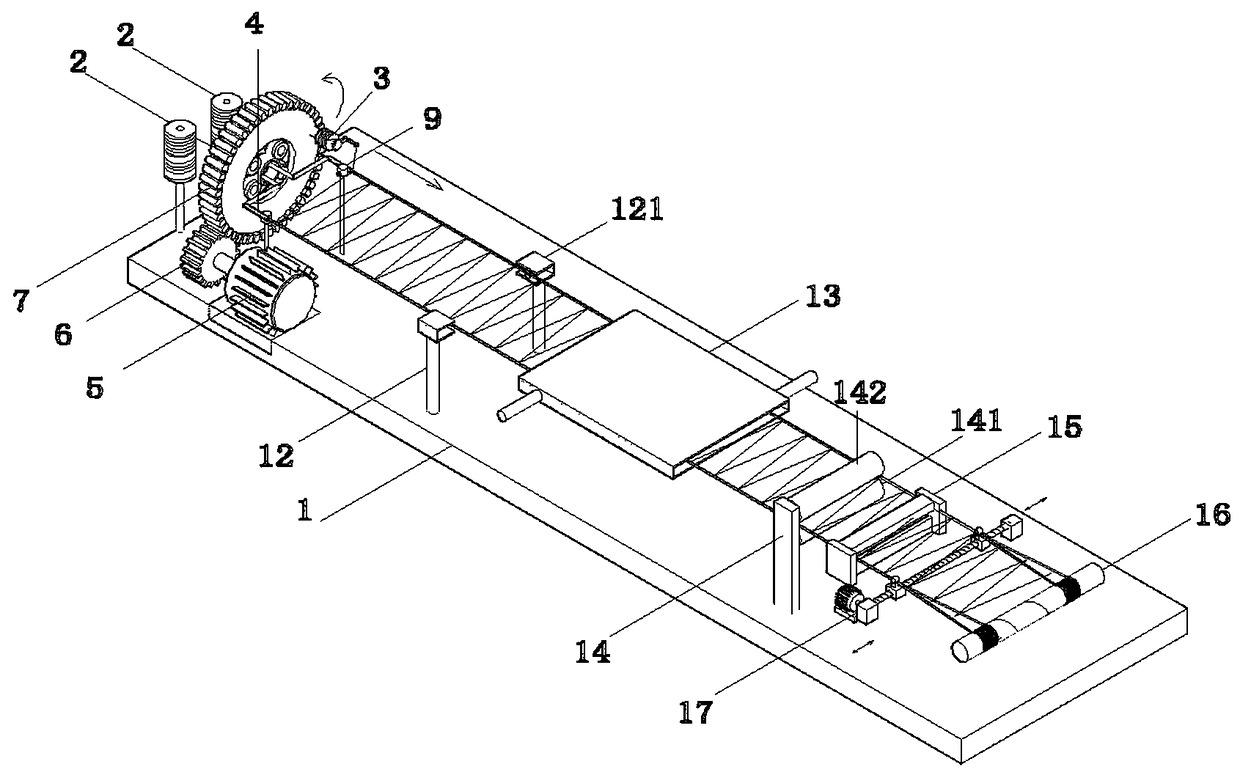

[0044] Such as figure 1 , 2 , 3, 4, 5, and 6, the production equipment of a kind of stretching net for vine crops described in this embodiment is used to prepare the stretching net for vine crops, and the stretching net includes warp threads arranged on both sides, and Two warp threads are fixedly connected and symmetrically arranged in adjacent positions. The continuous warp thread includes a frame 1 and a wire winding mechanism, a shaping mechanism and a winding mechanism arranged on the frame 1 .

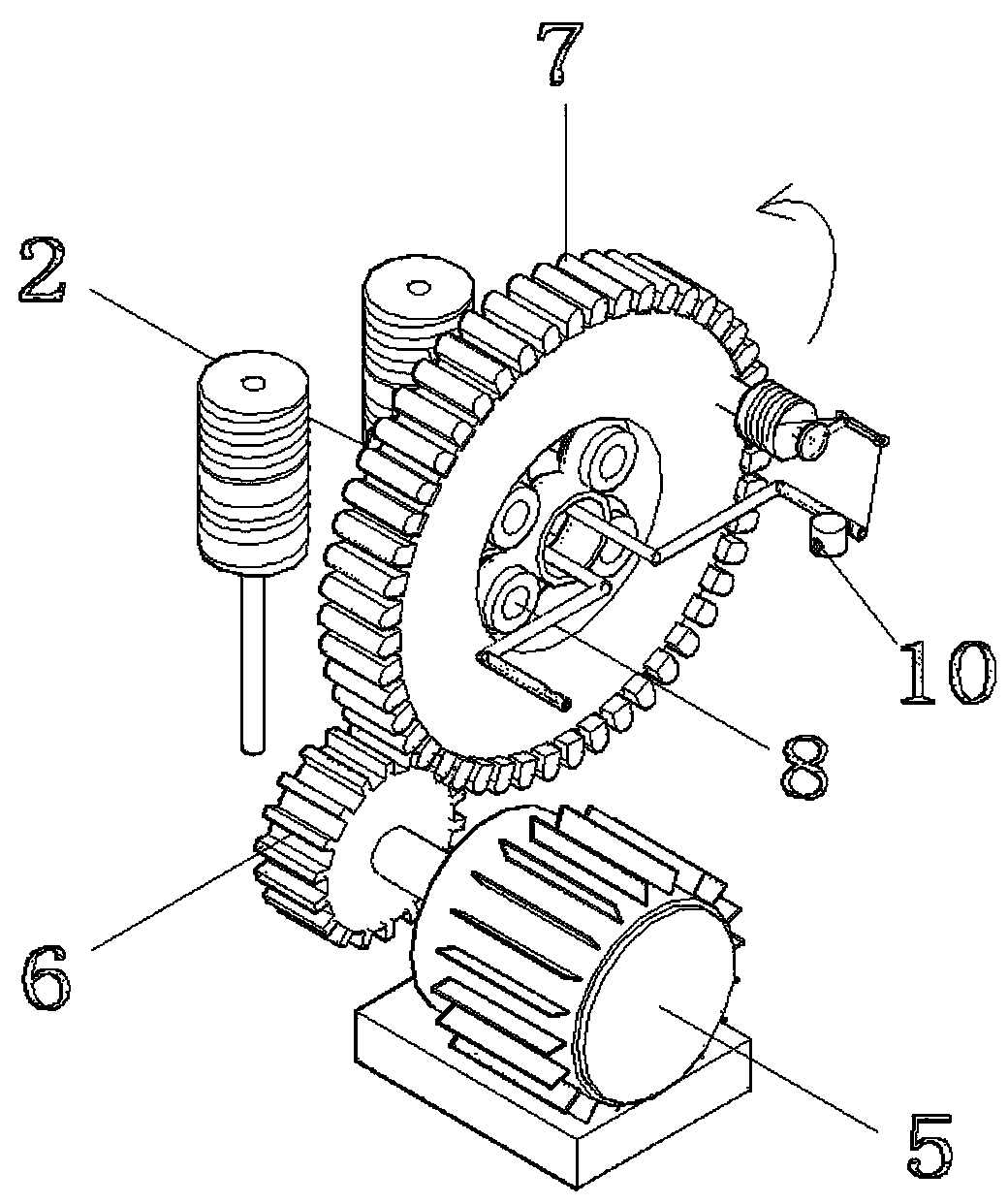

[0045] The wire winding mechanism includes a warp wheel 2, a weft wheel 3, a warp frame 4 and a coating mechanism, and also includes a winding support group composed of a power source 5, a transmission gear 6, a winding gear 7, and a winding gear supporting wheel 8. .

[0046] The warp wheel 2 is arranged at the front end of the frame 1, and the warp wheel 2 can be arranged vertically or horizontally, and its unwinding shaft is controlled by a motor to rotate, and a magnetic po...

Embodiment 2

[0054] Such as figure 2 , 3 , 4, 5, 7, and 8, the production equipment of a kind of stretching net special for vine crops described in this embodiment is basically the same in structure as in Embodiment 1, the difference is that in order to avoid The netting is extruded and deformed, and the tension pulley 14 is set to be composed of two or more sets of steel rollers 141, rubber rollers 142 and high friction belts 143, wherein the steel rollers 141 and rubber rollers 142 are arranged crosswise and misaligned. The net is clamped between two sets of belts 143, which has sufficient friction, and does not require too much pressure from the steel roller 141 and rubber roller 142, which avoids the net being squeezed and deformed, and at the same time ensures sufficient tension on the net force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com