Polymeric cement concrete additive and preparation method thereof

A technology for cement concrete and additives, applied in the field of concrete additives, can solve the problems of poor concrete material strength, fluidity, durability and impermeability, low requirements for equipment and reaction conditions, and single function, and achieve excellent cement additives. The effect of grinding effect, equipment and reaction conditions is not high, and the components are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

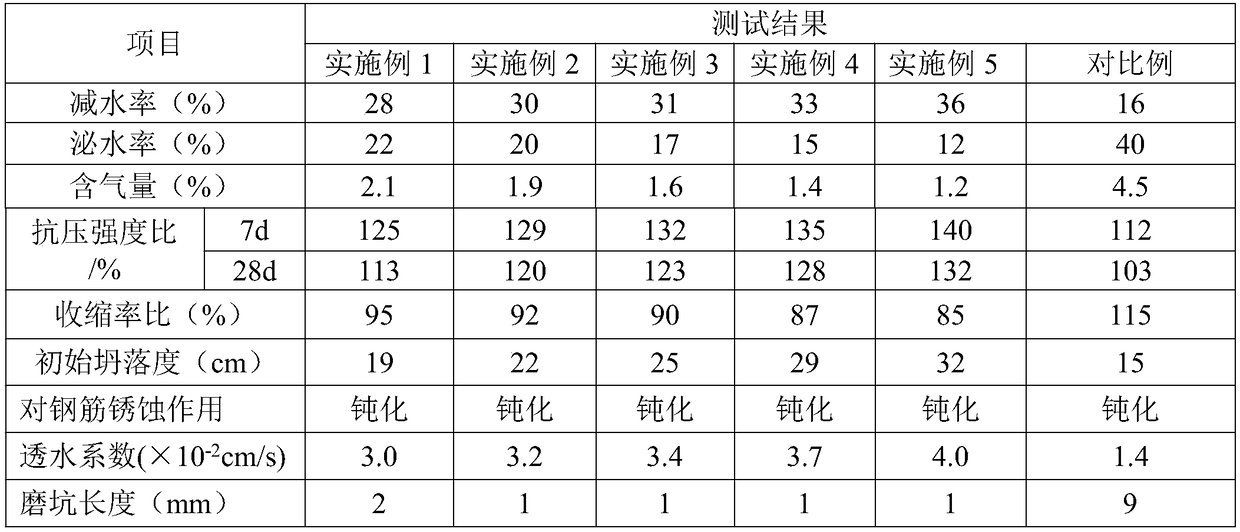

Examples

Embodiment 1

[0027] A preparation method of a polymer cement concrete additive, comprising the steps of:

[0028] 1) Dissolve 10 g of furan-2,3,4,5-tetracarboxylic acid and 17.8 g of glycerol propoxy triglycidyl ether in 50 g of dimethyl sulfoxide to form a solution, and then add 3 g of triphenylphosphine to it, Under a nitrogen atmosphere, stir and react at 100°C for 10 hours, then precipitate in acetone, filter, and wash with acetone for 3 times, and remove the acetone by rotary evaporation to obtain a polycondensate of furan ethers;

[0029] 2) Dissolve 20 g of the furan ether polycondensate prepared in step 1) in 50 g of isopropanol, and add 10 g of 1-naphthylamine-3,6,8-trisulfonic acid disodium salt to it, at 70°C The reaction was stirred for 6 hours, and the isopropanol was removed by rotary evaporation to obtain a furan ether polycondensation product modified by naphthyl sulfonate;

[0030] 3) Dissolve 20 g of the furan ether polycondensate modified by naphthyl sulfonate prepared ...

Embodiment 2

[0033] A preparation method of a polymer cement concrete additive, comprising the steps of:

[0034] 1) Dissolve 10 g of furan-2,3,4,5-tetracarboxylic acid and 17.8 g of glycerol propoxy triglycidyl ether in 60 g of N,N-dimethylformamide to form a solution, and then add three 3.5 g of ethylamine, stirred and reacted at 105° C. for 10.5 hours under a helium atmosphere, then precipitated in acetone, filtered, and washed with acetone 4 times, and the acetone was removed by rotary evaporation to obtain a polycondensate of furan ethers;

[0035] 2) Dissolve 22 g of the furan ether polycondensate prepared in step 1) in 53 g of ethanol, and add 9 g of 1-naphthylamine-3,6,8-trisulfonic acid disodium salt to it, and stir at 73°C After reacting for 6.5 hours, the ethanol was removed by rotary evaporation to obtain a furan ether polycondensate modified by naphthyl sulfonate;

[0036] 3) Dissolve 22 g of the furan ether polycondensate modified by naphthyl sulfonate prepared in step 2) in...

Embodiment 3

[0039] A preparation method of a polymer cement concrete additive, comprising the steps of:

[0040] 1) Dissolve 10 g of furan-2,3,4,5-tetracarboxylic acid and 17.8 g of glycerol propoxy triglycidyl ether in 70 g of N-methylpyrrolidone to form a solution, and then add tetrabutyl bromide Ammonium 4g, stirred and reacted at 110°C for 11 hours under a helium atmosphere, then precipitated in acetone, filtered, and washed with acetone for 5 times, and the acetone was removed by rotary evaporation to obtain a polycondensate of furan ethers;

[0041] 2) Dissolve 24 g of the furan ether polycondensate prepared in step 1) in 63 g of dichloromethane, and add 9 g of 1-naphthylamine-3,6,8-trisulfonic acid disodium salt to it, at 76°C Stirring and reacting for 7 hours, and then rotary steaming to remove dichloromethane to obtain a furan ether polycondensation product modified by naphthyl sulfonate;

[0042] 3) Dissolve 23 g of the furan ether polycondensate modified by naphthyl sulfonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com