Ash conveying system of coal-fired power plant

A technology for power plants and ash transportation, which is applied to conveyors, transportation and packaging, and transportation of bulk materials. It can solve problems that affect the normal production, affect the normal operation of equipment, increase maintenance costs, etc., and achieve economic value and energy-saving society. The benefits are considerable, the maintenance cost is saved, and the effect of saving electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. What needs to be declared here is that the descriptions of these specific implementations are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features and technical means involved in the various specific embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

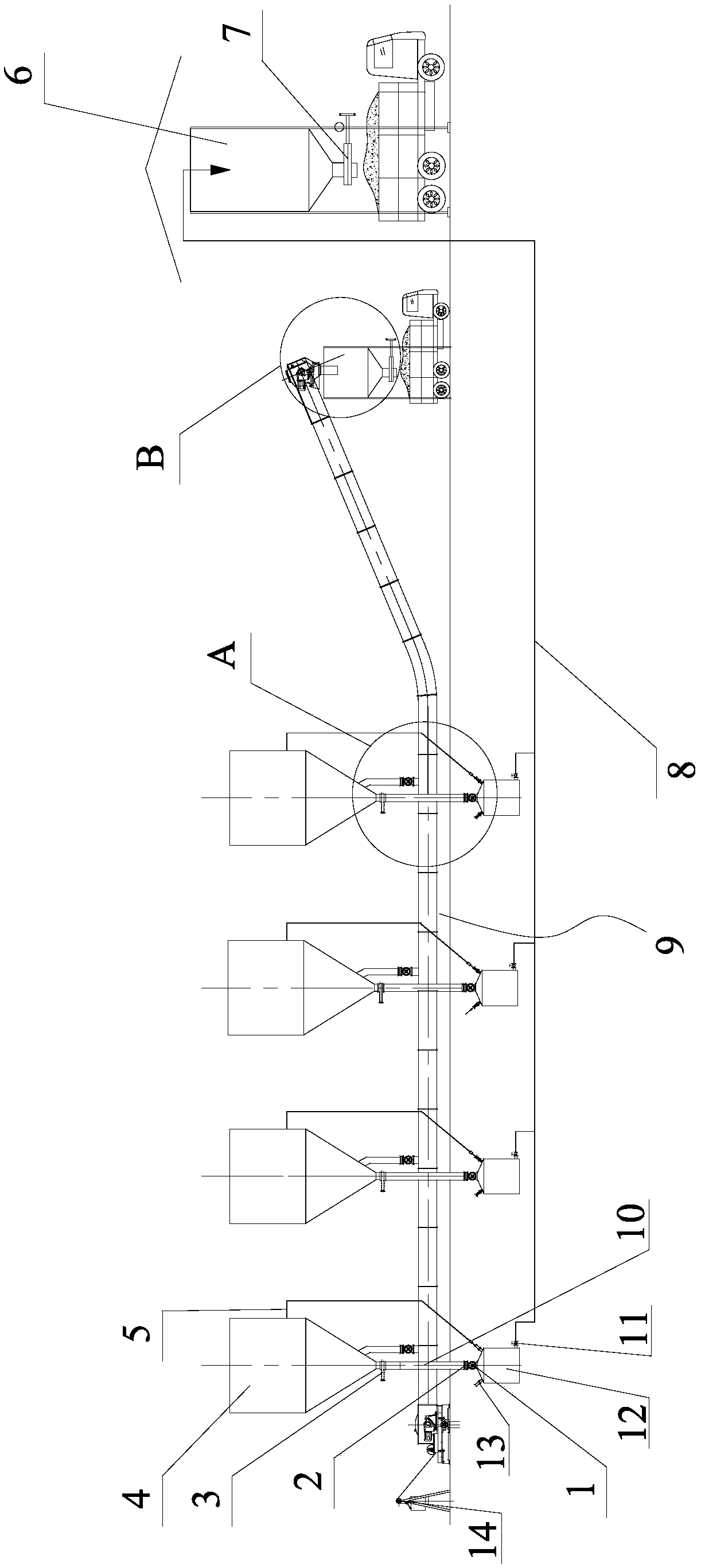

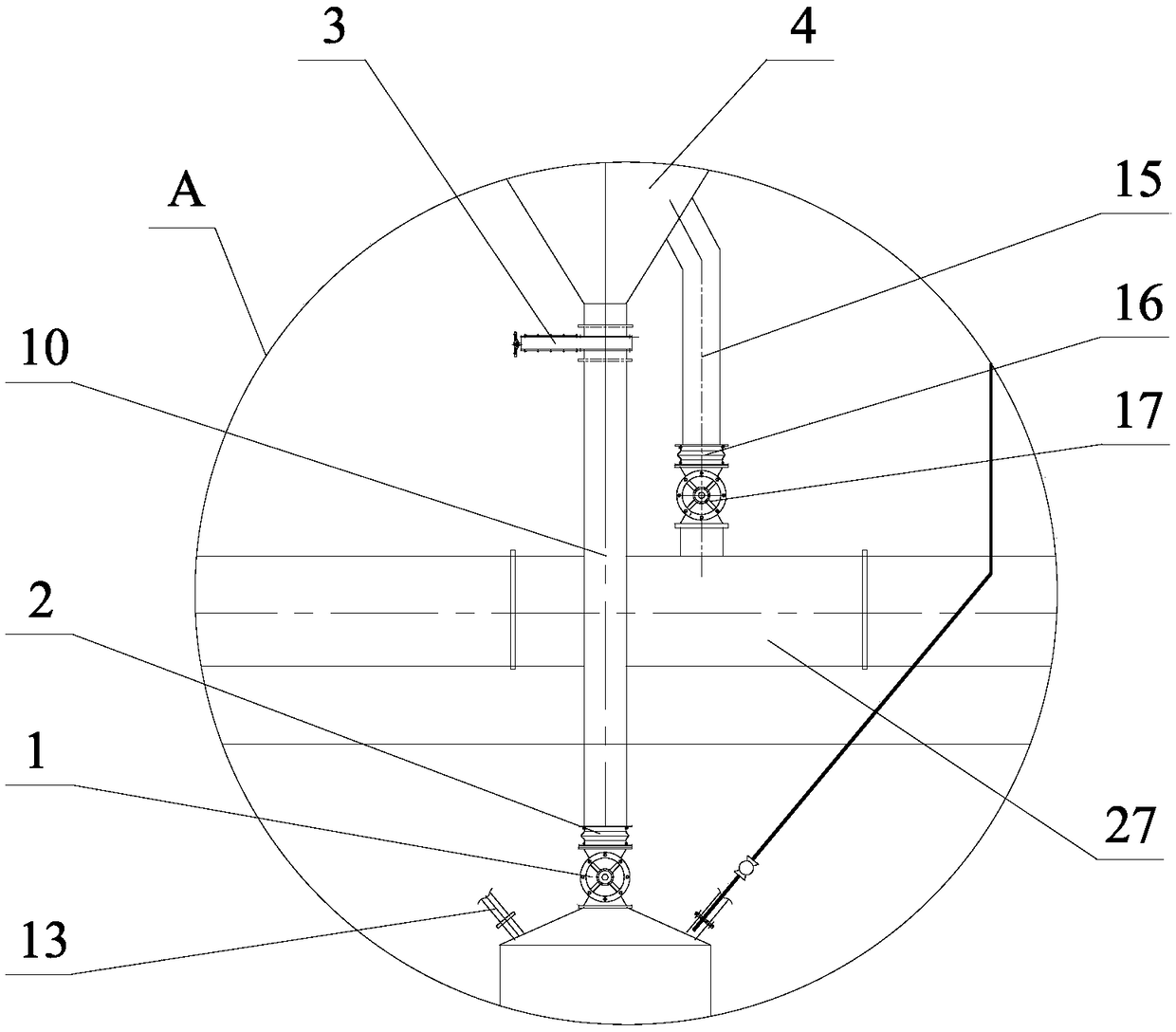

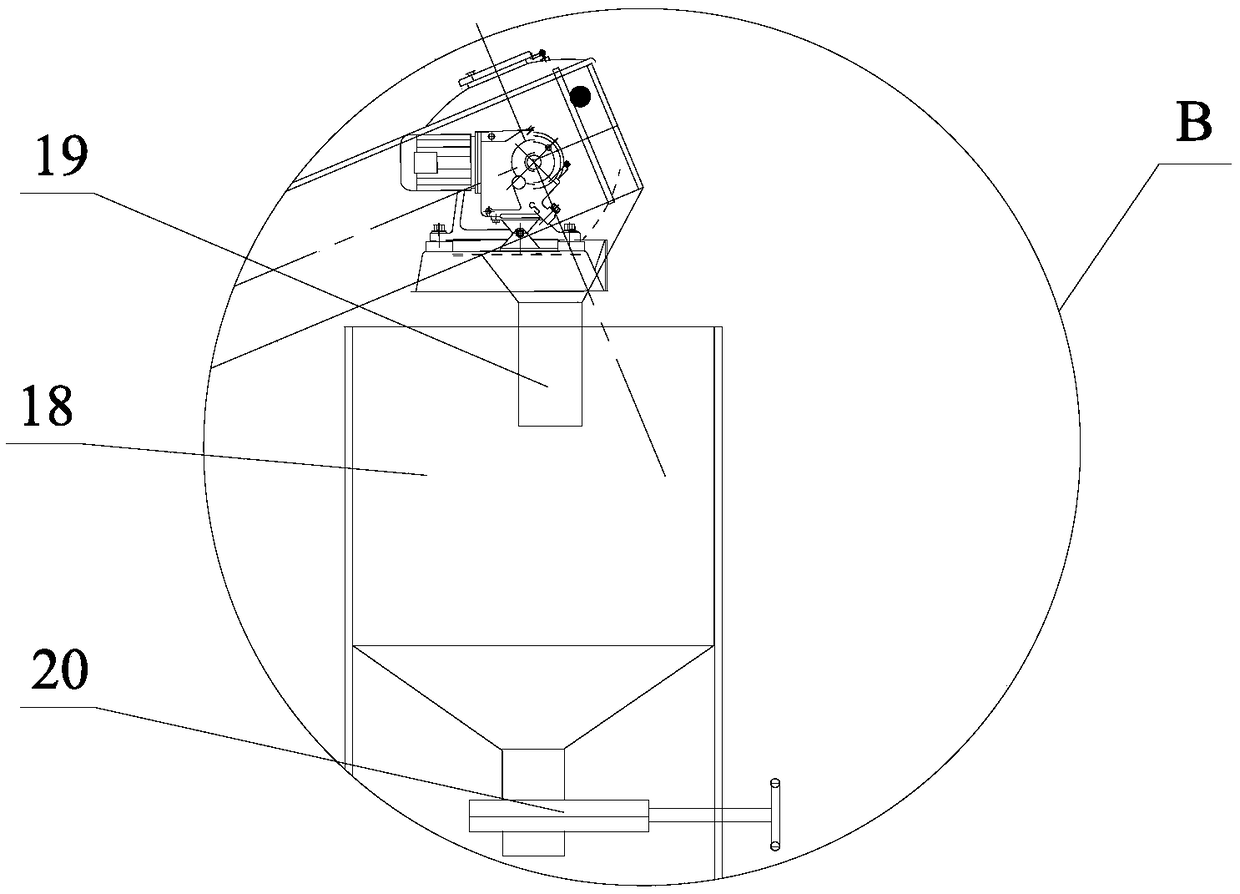

[0020] like figure 1 , figure 2 , image 3 As shown, the coal-fired power plant ash conveying system of the present invention includes a plurality of ash hoppers 4 for collecting the fly ash of the electric precipitator, each ash hopper 4 has a warehouse pump feed valve 1 below it, and the first ash discharge connecting pipe 10 is connected to the warehouse Pump feed valve 1 and a storage pump ash storage tank 12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com