Method for rapidly preparing h0h oriented MFI molecular sieve membrane by microwave heating method

A technology of microwave heating and molecular sieves, which is applied in separation methods, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of complex seed crystal coating methods, expensive and other problems, and achieve shortened synthesis time, cost savings, and good repeatability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

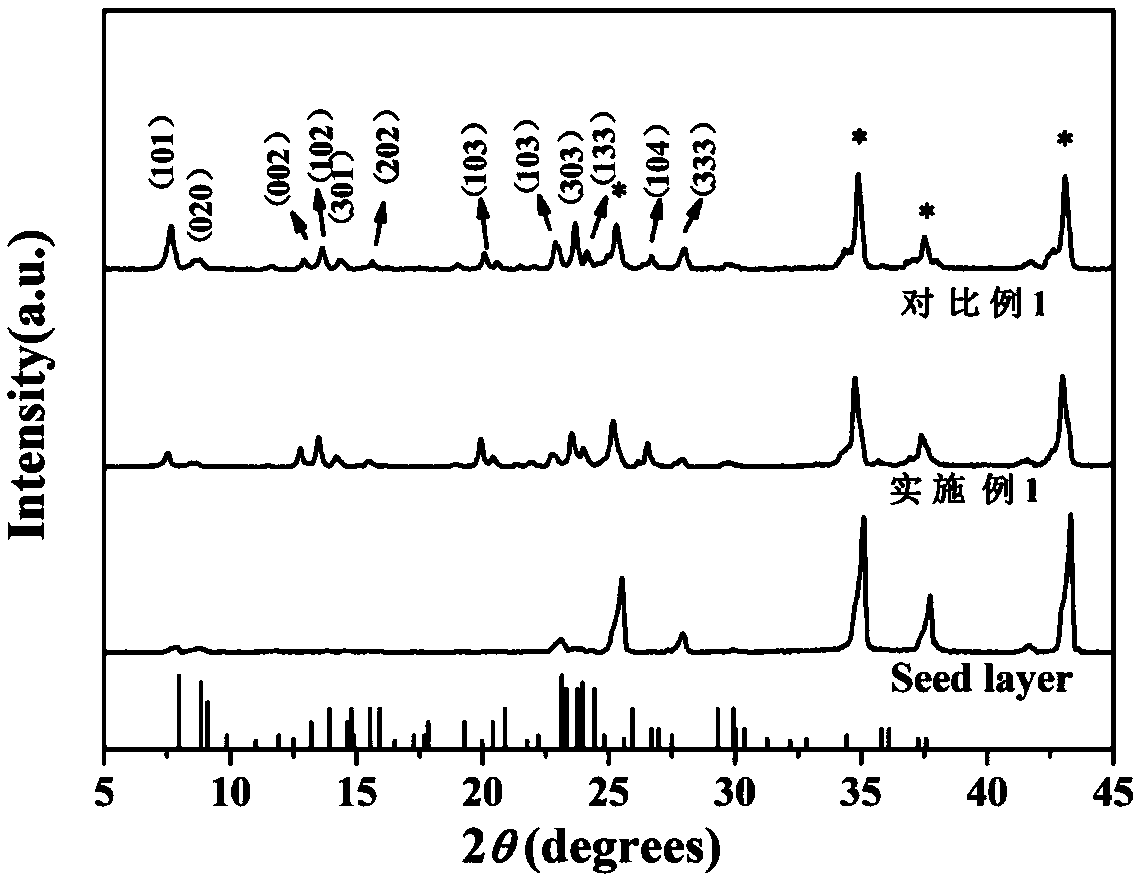

Embodiment 1

[0029] A kind of microwave heating method preparation hoh The method for orientation MFI type molecular sieve film, comprises the steps:

[0030] (1) Preparation of seed crystals: Mix silicon powder, sodium hydroxide, structure-directing agent tetrapropylammonium bromide and water to form a sol with a molar ratio of: H 2 O / SiO 2 =20, SDA / SiO 2 =0.05, NaOH / SiO 2 = 5, after the sol was aged, it was synthesized under microwave heating at a controlled reaction temperature of 110°C for 0.5 h, and the prepared crystals were washed with deionized water and centrifuged to obtain molecular sieve crystal seeds;

[0031](2) Support coating seed crystals: Weigh 1.0 g ellipsoidal MFI molecular sieve crystals and add them to 1000 g ethanol solution (99.9 wt%). After ultrasonic and vibration treatment, the crystals are evenly dispersed in ethanol solution to form a uniform The molecular sieve suspension, the suspension mass fraction is 0.25%. Put the porous carrier vertically into the m...

Embodiment 2

[0043] (1) Preparation of seed crystals: Mix sodium silicate, sodium hydroxide, structure directing agent tetrapropylammonium hydroxide and water to form a molar ratio of sol: H 2 O / SiO 2 =100, SDA / SiO 2 =0.5, NaOH / SiO 2 = 20, after the sol was aged, it was synthesized under microwave heating at a controlled reaction temperature of 200°C for 5 h, and the prepared crystals were washed with deionized water and centrifuged to obtain molecular sieve crystal seeds;

[0044] (2) Support coated with seed crystals: the preparation process is the same as step 2 of Example 1, except that the suction pressure is 0.08 MPa and the time is 20 seconds.

[0045] (3) hoh Synthesis of oriented MFI molecular sieve membrane: the preparation process is the same as Step 3 of Example 1, except that the structure directing agent in the synthesis sol is tetrapropylammonium iodide, and the aging time of the sol is 12 h. The synthetic sol in the reactor submerged the support body by 3 cm, the microw...

Embodiment 3

[0048] (1) Preparation of seed crystals: the preparation process is the same as Step 1 of Example 1.

[0049] (2) Support coated with seed crystals: the preparation process was the same as step 2 of Example 1, except that the suction pressure was 0.08 MPa, the time was 5 seconds, and the concentration of the seed crystal suspension was 4%.

[0050] (3) hoh Oriented MFI type molecular sieve membrane synthesis: the preparation process is the same as in Example 1 step (3), except that the molar ratio of each component of the synthetic sol is: H 2 O / SiO 2 =600, TPABr / SiO 2 =0.1, NaOH / SiO 2 = 0.5. The silicon source used was tetramethyl orthosilicate.

[0051] The prepared membrane M3 was used for n- / i-C 4 h 10 The gas separation performance was characterized in the (50 / 50) system, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com