Variable doped GaN nanowire array photocathode and preparation method thereof

A nanowire array and photocathode technology, which is applied in the manufacture of light-emitting cathodes, photoemission cathodes, nanotechnology, etc., can solve the problems of long transport distances and high emissivity of photoelectrons, so as to improve photoemission quantum efficiency and increase photocurrent , Improve the transport efficiency in the body and the effect of surface escape probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

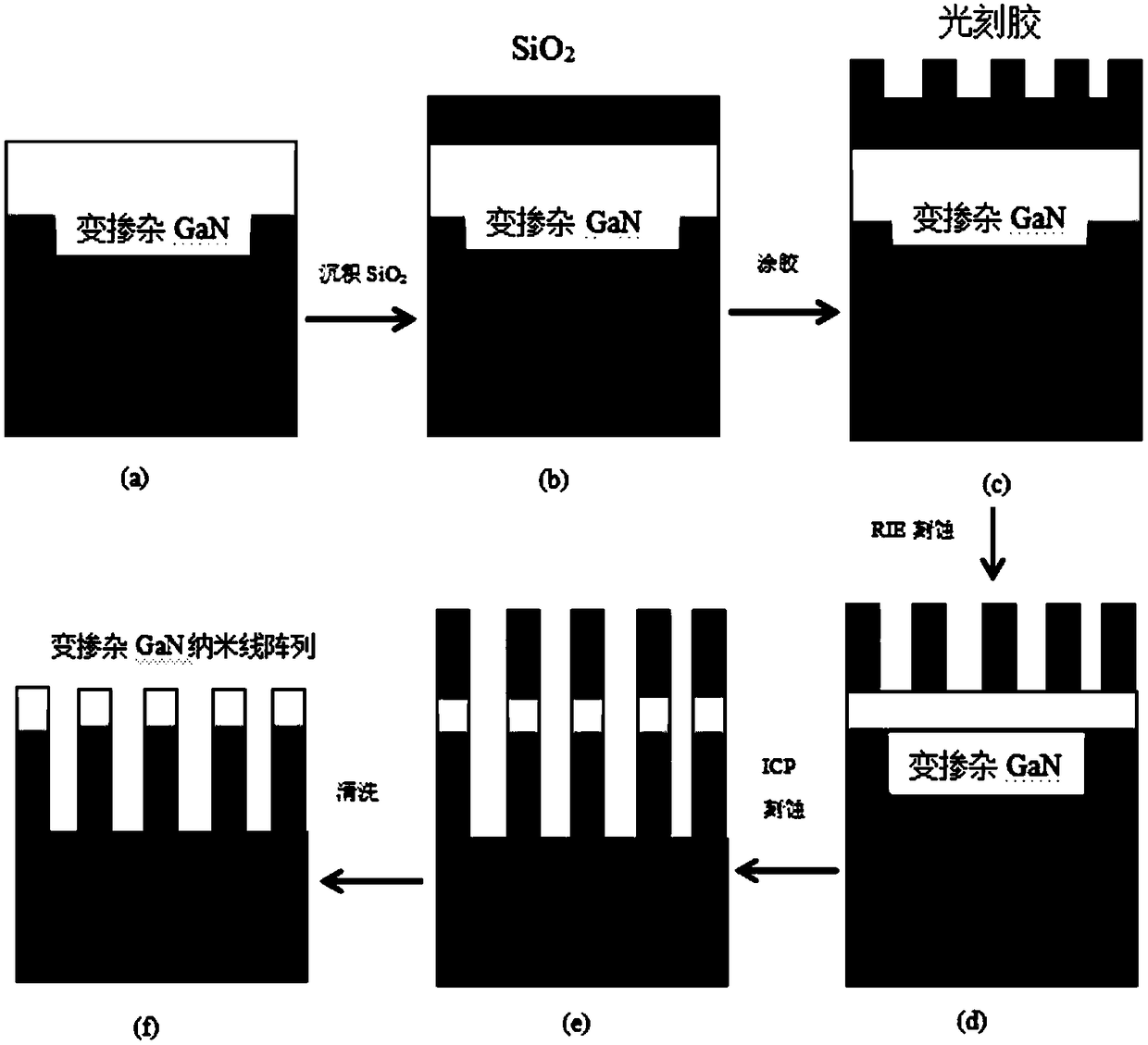

[0027] combine figure 2 As shown, a method for preparing a variable doped GaN nanowire array photocathode, the specific steps are:

[0028] Step 1. On the surface of the substrate, an AlN buffer layer is grown by an MOCVD growth process;

[0029] In a further embodiment, an AlN buffer layer with a thickness of 100-200 nm is grown by MOCVD.

[0030] Step 2. Epitaxially grow a p-type variable doped GaN film on the AlN buffer layer by MOVCD method and p-type doping process, and deposit SiO on the film by PECVD method 2 Layer as a mask, photolithographic exposure and development;

[0031] In some embodiments, a p-type GaN thin film with a variable doping structure with a total thickness of 5-25 μm is grown on the surface of the AlN buffer layer by MOCVD method and a p-type doping process of GaN material, and the doping element is Mg, The range of doping concentration is controlled within 10 16 ~10 19 cm -3 between, and the concentration gradually decreases from the surface ...

Embodiment 1

[0044] to combine figure 1 As shown, the variable-doped GaN nanowire array photocathode of the present invention includes a Si substrate 1, an AlN buffer layer 2, a photoemissive layer 3 and a Cs / O active layer 4, and on the surface of the Si substrate layer, a An AlN buffer layer with a thickness of 200nm, and then grow a p-type GaN film with a total thickness variable doping structure on the surface of the AlN buffer layer through the MOCVD method and the p-type doping process of GaN materials, with a thickness of 25 μm, and the variable doping layer It is 15 layers, doped with Mg element, each layer has the same thickness, and the corresponding doping concentration is N 1 , N 2 ,...,N 15 , with a thickness of l 1 The doping concentration N 1 1×10 19 cm -3 , concentration from N 1 to N 15 Gradually decreased, a layer of 2.3μm thick SiO was deposited by PECVD 2 layer as a protective layer, and then coated with a layer of 1.6μm AZ5214 photoresist, after exposure and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com