A hydrogen adsorption storage release system and its application

A release system, hydrogen technology, applied in gas treatment/storage effect, gas/liquid distribution and storage, fixed-capacity gas storage tank, etc., can solve the problems of material physical and chemical properties degradation, occupying adsorbent space, limited adsorption capacity, etc. Achieve the effect of improving hydrogen storage-dehydrogenation efficiency, improving the influence of thermal effect, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

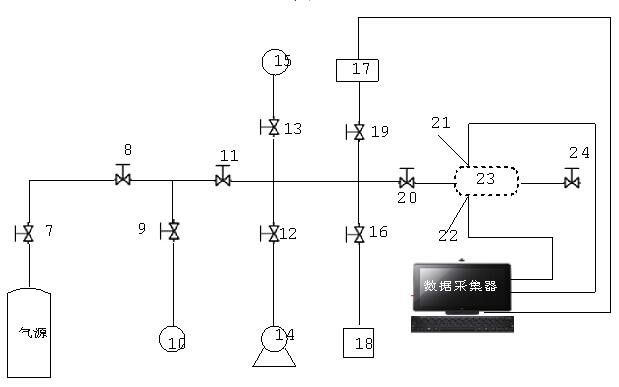

Method used

Image

Examples

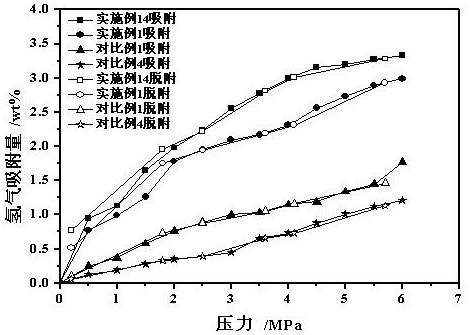

Embodiment 1

[0031] The metal-organic framework material uses zirconium-based metal-organic framework material UiO-66, and UiO-66 is synthesized by solvothermal method: 15mmol ZrCl 4 and 15mmol of phthalic acid were dissolved in 115mL of DMF solvent, and ultrasonically treated for 10min; then the reaction solution was placed at 120°C, kept at a constant temperature for 24h, cooled to room temperature, and the solvent was removed by suction filtration, and the filter cake was washed once with DMF and methanol respectively , dried at 80°C for 12h to obtain UiO-66 powder.

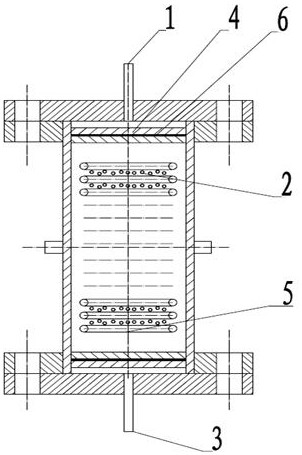

[0032] Weigh 100g of UiO-66, 30g of paraffin wax with a phase transition temperature of 45°C and 5g of deionized water, and prepare a core-shell hydrogen storage material through a centrifugal coating granulator. Among them, the power of the centrifugal coating granulator is 5KW, the working room temperature is 40°C, and the rotating speed of the turntable is 230rpm. A spherical core-shell hydrogen storage material with a...

Embodiment 2

[0035] In Example 1, lauric acid with a phase transition temperature of 45° C. was selected to replace paraffin wax with a phase transition temperature of 45° C., and other reaction conditions and material compositions were kept unchanged to obtain the adsorption storage release system B.

Embodiment 3

[0037] In Example 1, neopentyl glycol with a phase transition temperature of 45° C. was selected to replace paraffin wax with a phase transition temperature of 45° C., and other reaction conditions and material compositions were kept unchanged to obtain an adsorption storage release system C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com