Two-factor sustained-release system based on poc and mesoporous nanospheres

A microsphere and mesoporous technology, applied in the field of nanotechnology and biomedicine, can solve the problems of difficult drug dispersion, affecting sample release rate, sample inhomogeneity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] In another preferred embodiment, the preparation method of the pharmaceutical composite film of the present invention includes the following steps:

[0068] (1) Anhydrous ethanol, deionized water, and ammonia were mixed with 10-20: 5-10: 1, and stirred at 25-40 ° C (preferably 30 ° C) for 30 to 50 min. Ethyl lysate was added to the above system, and stirred for 40 to 60 min. The uniform mixture of orthosate esters and silane coupling agents in advance was added, stirred by stirring 80 to 100 min, and dispersed from 0.5-2 mol / ml (preferably 1.0 mol / ml) Na after centrifugation. 2 CO 3 In the solution, the dispersed sol was then stirred at 60-90 ° C (preferably 80 ° C), washed 3 times in centrifugation, freeze drying to obtain a hollow diaphragm SiO 2 Microspheres.

[0069] (2) Take an appropriate amount of hollow mesoporous SiO obtained in step (1) 2 The microspheres were dispersed in ethanol solutions of hydrophobic drugs, 40 to 60 ° C, stirring 2 to 4 days, freeze dryin...

Embodiment 1

[0080] Hollow mesh SiO 2 Microsphere preparation

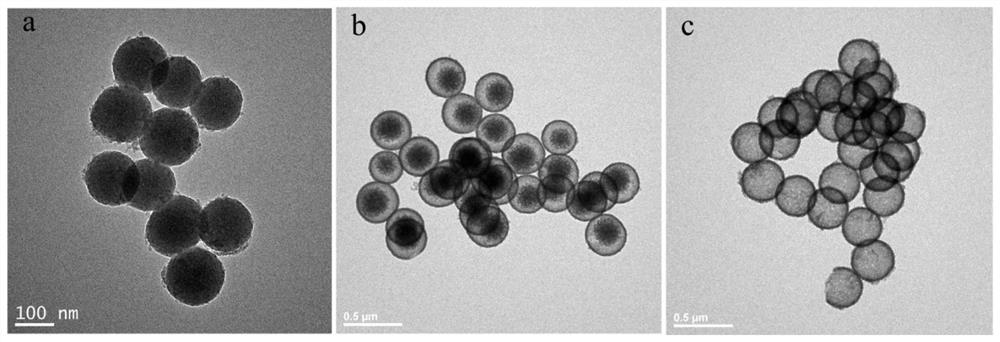

[0081] 65 ml of anhydrous ethanol, 10 ml of deionized water, 2.75 ml ammonia were mixed, and stirred at 30 ° C for 30 min. 6 ml of orthosilicate was added to the above system, stirred for 40 min. 5 ml of 5 ml of 5 ml of 5 ml of 5 ml of 5 ml of 5 ml of 5 ml of 3.5 ml of 3-aminopropyltrimethoxysilane was added, stirred for 80 min, separated from centrifugation, washed once. After centrifugation of the product, stirred from 200 ml of 1.0 mol / L of NA 2 CO 3 In the solution, the dispersed sol was stirred at 80 ° C for 60 min, and the deionized water was washed 3 times, and the addition of the product was obtained. Transmission electron microscopy figure 1 C, the size is one, and the microspheres are uniform, no serious agglomeration.

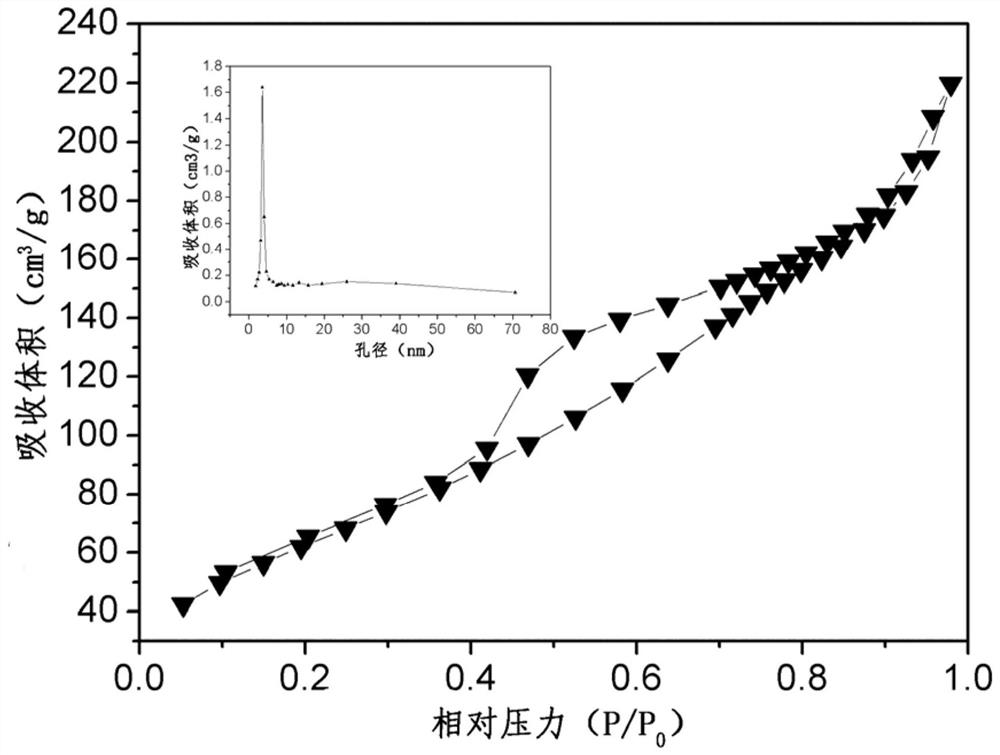

[0082] Nitrogen adsorption desorption experiment figure 2 The curve has a stranded ring phenomenon, indicating the hollow SIO 2 There is a mesh structure in the microsphere. According to the calculatio...

Embodiment 2

[0085] Hollow mesh SiO 2 Microsphere preparation

[0086] In the same embodiment, the step in the step is Na 2 CO 3 The concentration of the solution was changed from 1.0 mol / L to 0.6 mol / L, and the other conditions were constant, and the mesh SiO was obtained. 2 Microspheres, transmission electron microscopy figure 1 A, the size is one, and the microspheres are uniform, no serious agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com