Preparation method of multifunctional high-efficiency foliar fertilizer

A foliar fertilizer and multi-functional technology, applied in the field of foliar fertilizer, can solve the problems of poor bacteriostatic and insecticidal effect of foliar fertilizer, high cost of disease and insect pest control, improved bacteriostatic and insecticidal effect, etc., so as to improve crop yield and quality. , The effect of reducing planting costs and long-lasting fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment relates to a multifunctional and high-efficiency foliar fertilizer and its preparation method. The foliar fertilizer consists of the following raw materials in parts by weight:

[0059] 1.5 parts of trace elements;

[0060] 2 parts of propylene sulfide;

[0061] 4 parts mugwort oil;

[0062] 1 part of glycyrrhizic acid;

[0063] Apigenin 1.5 parts;

[0064] 16 parts of attapulgite powder;

[0065] 6 parts of propylene glycol;

[0066] 1 part of water-soluble highland barley β-glucan;

[0067] 2 parts of compound bacteria powder;

[0068] 2.5 parts of amino acid powder;

[0069] 30 parts of natural plant extracts;

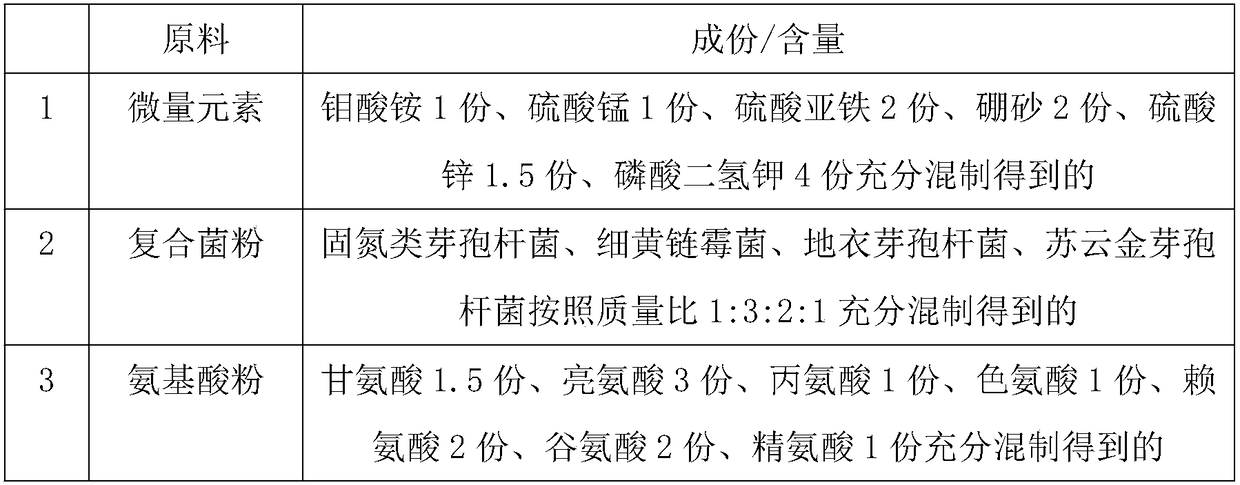

[0070] The selection and preparation of trace elements, composite bacterial powder and amino acid powder in the present embodiment are shown in Table 1 below:

[0071] Table 1

[0072]

[0073] In addition, the natural plant extract is prepared through the following steps: take fresh mignonette and olive leaves according to the we...

Embodiment 2

[0080] This embodiment relates to a multifunctional and high-efficiency foliar fertilizer and its preparation method. The foliar fertilizer consists of the following raw materials in parts by weight:

[0081] 1.8 parts of trace elements;

[0082] 2.4 parts of propylene sulfide;

[0083] 4.5 parts of mugwort oil;

[0084] 1.2 parts of glycyrrhizic acid;

[0085] Apigenin 1.75 parts;

[0086] 17 parts of attapulgite powder;

[0087] 6.5 parts of propylene glycol;

[0088] 1.15 parts of water-soluble highland barley β-glucan;

[0089] 2.25 parts of compound bacteria powder;

[0090] 2.8 parts of amino acid powder;

[0091] 34 parts of natural plant extracts.

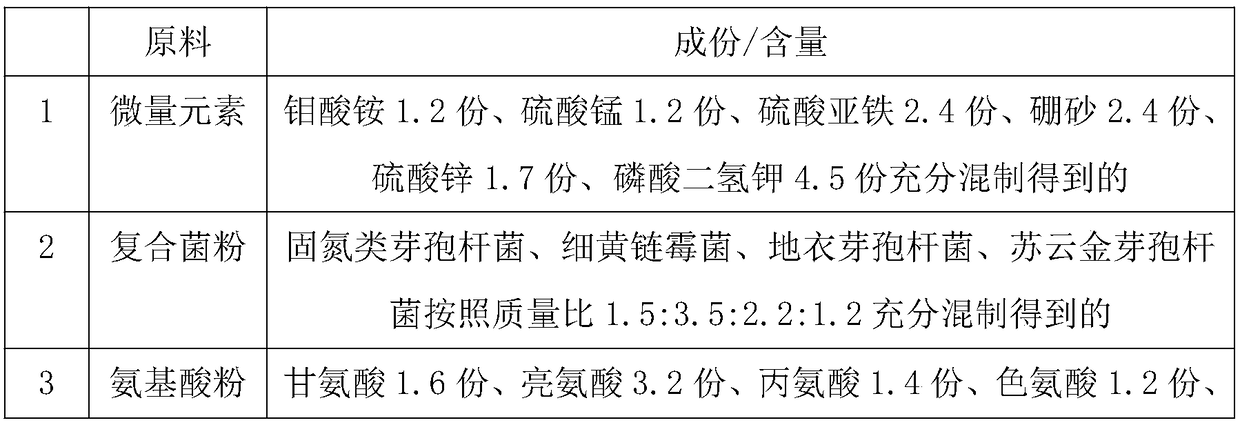

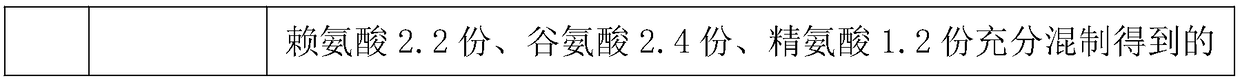

[0092] The selection and preparation of trace elements, composite bacterial powder and amino acid powder in the present embodiment are shown in Table 2 below:

[0093] Table 2

[0094]

[0095]

[0096] In addition, the natural plant extract is prepared through the following steps: take fresh mignonette and ...

Embodiment 3

[0103] This embodiment relates to a multifunctional and high-efficiency foliar fertilizer and its preparation method. The foliar fertilizer consists of the following raw materials in parts by weight:

[0104] 2 parts of trace elements;

[0105] 2.6 parts of propylene sulfide;

[0106] 5 parts mugwort oil;

[0107] 1.5 parts of glycyrrhizic acid;

[0108] 2 parts apigenin;

[0109] 18 parts of attapulgite powder;

[0110] 7 parts of propylene glycol;

[0111] 1.25 parts of water-soluble highland barley β-glucan;

[0112] 2.5 parts of compound bacteria powder;

[0113] 3 parts amino acid powder;

[0114] 35 parts of natural plant extracts;

[0115] 0.4 part of surfactant.

[0116] The selection and production of trace elements, composite bacteria powder, amino acid powder and surfactant in the present embodiment are shown in Table 3 below:

[0117] table 3

[0118]

[0119] In addition, the natural plant extract is prepared through the following steps: Take fresh m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com