A process for treating coal chemical wastewater

A technology for coal chemical wastewater and process, applied in the field of coal chemical industry, can solve problems such as the influence of dephenolization rate, and achieve the effects of reducing energy consumption, good effect and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

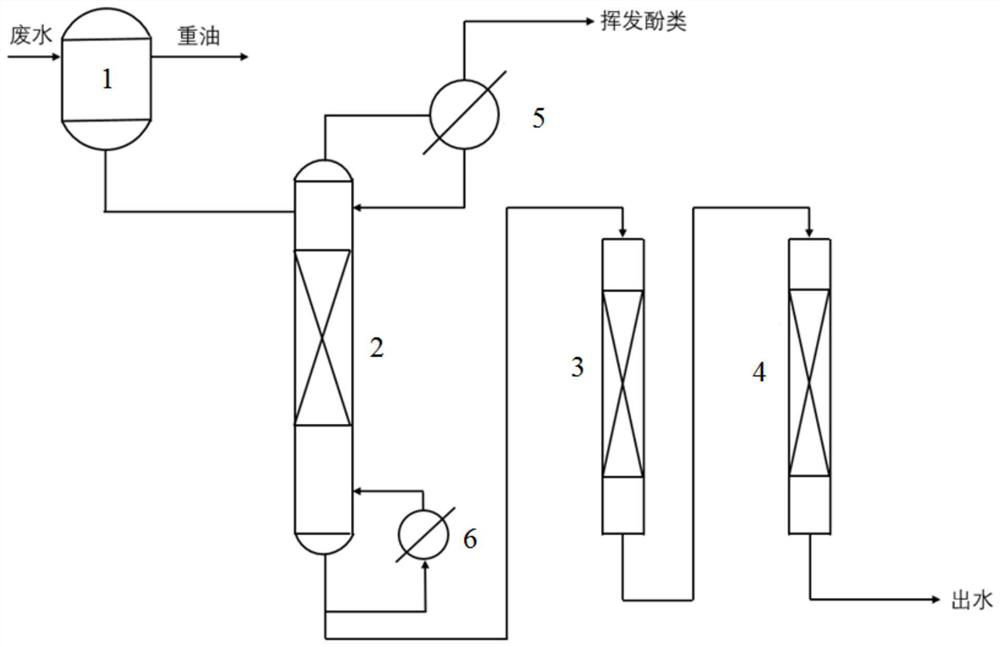

Image

Examples

preparation example Construction

[0039] The preparation method of modified activated carbon is: mix 100g of biomass-based activated carbon with ammonium persulfate solution with a mass fraction of 10% according to the volume ratio of 1:5, treat at 40°C for 2h, filter, wash with water to become neutral, 100 Dry at ℃ to obtain surface enriched OH - modified activated carbon.

[0040] The preparation method of the sulfonated modified adsorption resin is as follows: 200g of XAD-7 macroporous adsorption resin is washed with 100g of methanol and 150g of water at room temperature (25°C) for 30 minutes to remove impurities. Swell the resin with 400mL of absolute ethanol for 1 hour, control the temperature at 80°C, slowly add 300mL of 98%wt concentrated sulfuric acid while stirring slowly, and keep it warm for 5h after adding; quickly cool with ice water and wash to medium After drying, the sulfonic acid group-modified resin is obtained; then the resin introduced into the sulfonic acid group is soaked in 400mL of 5wt...

Embodiment 1

[0042] Control coal chemical wastewater (total ammonia nitrogen content is 8000mg / L, total phenol content is 13000mg / L, of which, volatile phenol content is 9000mg / L, non-volatile phenol content is 4000mg / L, COD is 12000mg / L, and heavy oil content is 5000mg / L) at a temperature of 30°C, and adjust the pH value to 5, first pass the wastewater into the coalescer at a flow rate of 5m / s, the working temperature of the coalescer is 65°C, and the heavy oil content in the waste water after passing through the coalescer Reduced to 96mg / L, COD value is 8560mg / L.

[0043] Then adjust the pH of the waste water to 10, pass the waste water into the rectification tower, the temperature at the top of the rectification tower is 108°C, and the pressure is 0.45MPag, and the light components are discharged from the top of the rectification tower, and the waste water after rectification treatment is self-refining The bottom of the distillation tower is discharged. After testing, the volatile phen...

Embodiment 2

[0057] Control coal chemical wastewater (total ammonia nitrogen content is 8000mg / L, total phenol content is 13000mg / L, of which, volatile phenol content is 9000mg / L, non-volatile phenol content is 4000mg / L, COD is 12000mg / L, and heavy oil content is 5000mg / L) at a temperature of 30°C, and adjust the pH value to 5, first pass the wastewater through the coalescer to remove oil at a flow rate of 4m / s, the heavy oil content in the wastewater after passing through the coalescer is 96mg / L, and the COD value is 8560mg / L.

[0058] Then adjust the pH of the waste water to 10, pass the waste water into the rectification tower, the temperature at the top of the rectification tower is 108°C, and the pressure is 0.45MPag, and the light components are discharged from the top of the rectification tower, and the waste water after rectification treatment is self-refining The bottom of the distillation tower is discharged; after testing, the volatile phenol content in the wastewater after rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com