Denitrification aerobic granular sludge sequencing batch reactor and work method thereof

A technology of aerobic granular sludge and sequencing batch reactor, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problem that cannot provide aerobic granular pollution The problem of less application of mud and integrated equipment, low oxygen utilization rate, etc., to achieve the effect of improving the path and residence time, superior mass transfer effect, and improving oxygen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

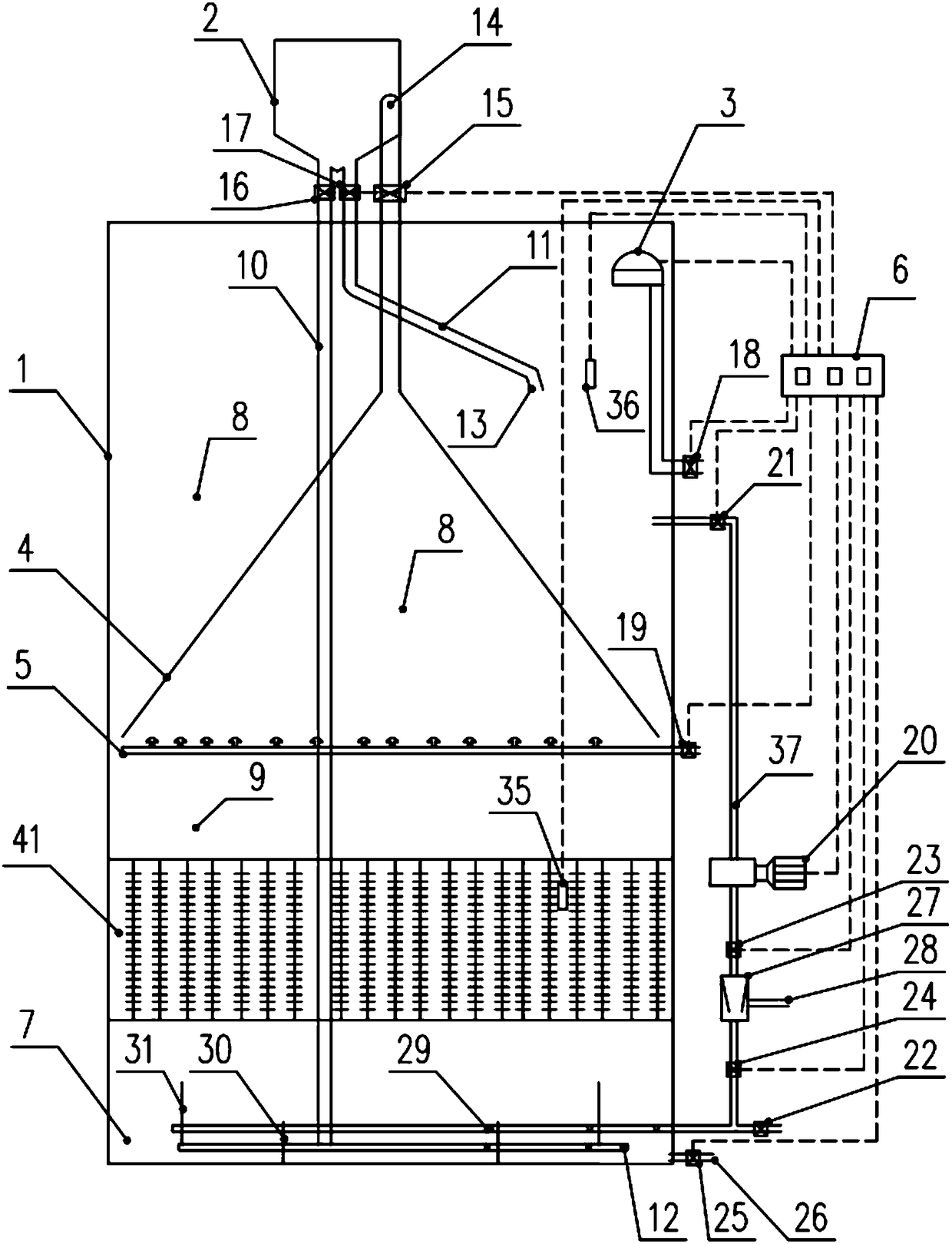

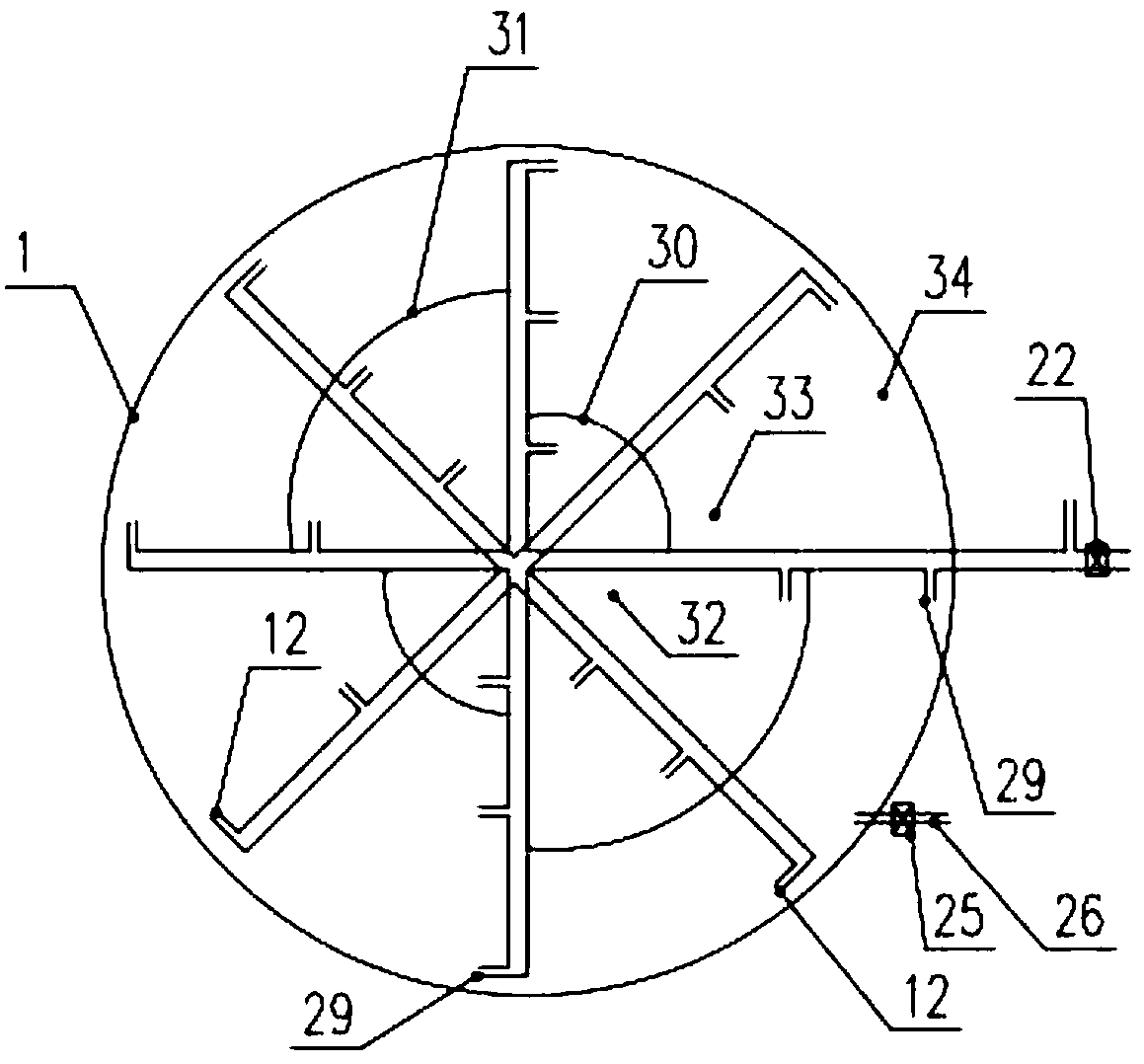

[0047] A nitrogen-removing aerobic granular sludge sequencing batch reactor, comprising a tank body 1, an aeration system 5, a water inlet pipe 26, a gas-water separator 2, an upper return pipe 11, an upper return nozzle 13, a lower return pipe 10, First cross pipe, lower backflow nozzle 12, gas collecting hood 4, air collecting pipe 14, decanter 3, drain pipe, external circulation pipe 37, external circulation pump 20, pipeline ejector 27, second cross pipe, internal diversion Plate 30, middle deflector 31 and biological rope packing layer 6;

[0048] The aerator system 5 is installed inside the tank body 1, above the aerator system 5 is the nitrification zone 8, below the aerator system 5 is the denitrification zone 9, and the space between the denitrification zone 9 and the bottom of the tank is the water distribution mixing zone 6;

[0049] The gas-water separator 2 is installed on the top of the tank body 1, one end of the upper return pipe 11 is connected to the bottom ...

Embodiment 2

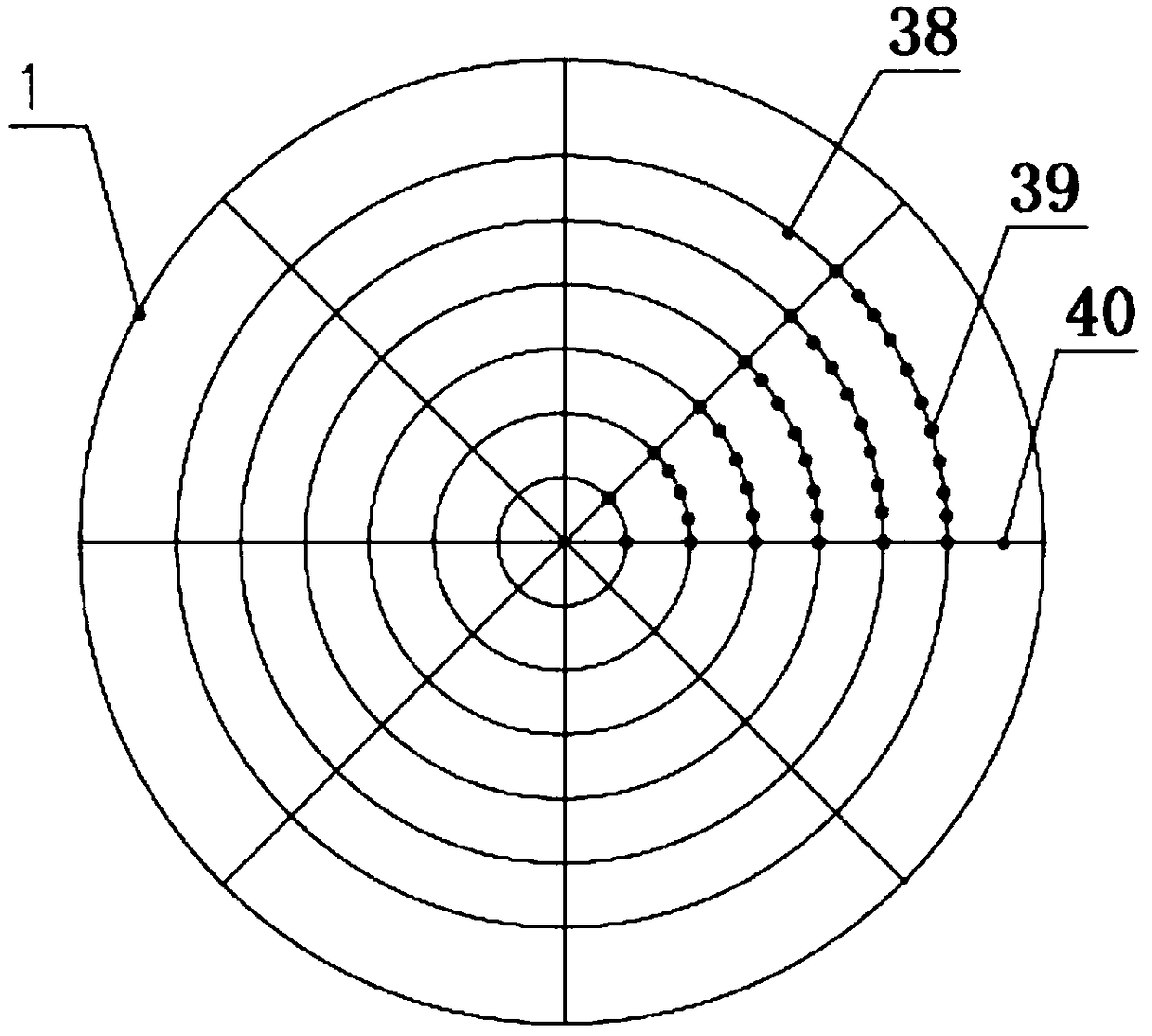

[0070] Biological rope packing 3, 9 spacing 20-40 centimeters.

[0071] The ratio of height to diameter of the tank body 1 is 1:1-4:1; the nitrification zone 8 is from the upper part of the aeration system 5 to the top of the tank, accounting for 1 / 2-2 / 3 of the height of the tank body 1; the denitrification zone 8 is the aeration system 5 From the bottom to the bottom of the tank, it accounts for 1 / 3-1 / 2 of the height of the tank body 1.

[0072] Both the tank body 1 and the gas-water separator 2 are columnar.

[0073] The water inlet pipe 26 enters the tank body 1 to 30-50 cm tangentially along the tank wall of the tank body 1

[0074] The number of upper return nozzles 13 is more than 3 groups and arranged evenly.

[0075] The gas collecting hood 4 is conical with the large diameter end of 30 °-65 ° on the lower small diameter end, and the large diameter end edge of the gas collecting hood 4 is 20-50 centimeters away from the tank body 1 cylinder wall.

[0076] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com