Reaction system for synthesizing silicon nitride powder

A reaction system, silicon nitride powder technology, applied in nitrogen compounds, chemical/physical/physical chemistry nozzle reactors, inorganic chemistry, etc. The effect of long time, smooth metal surface and high thermal power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

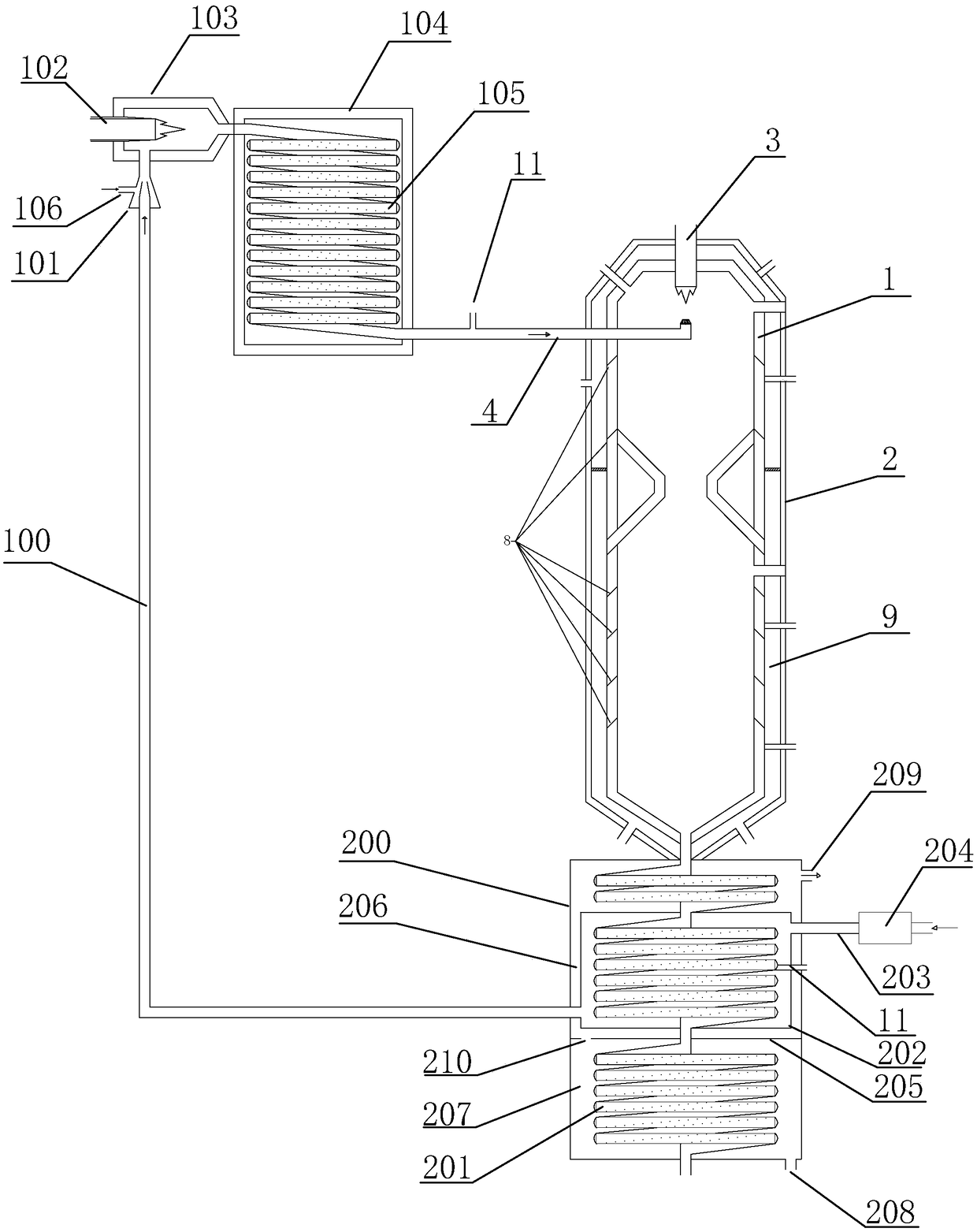

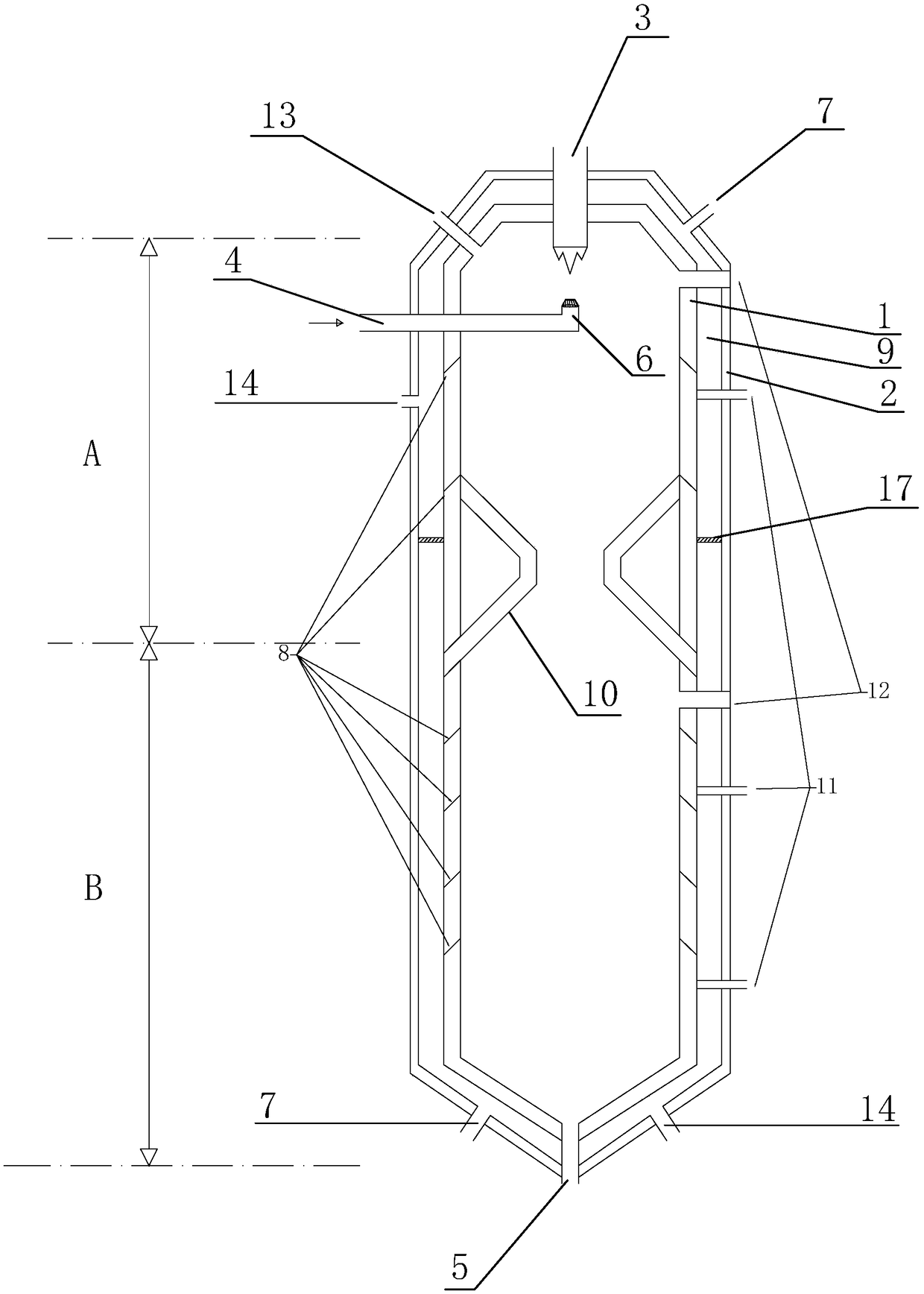

[0080] Such as figure 1 As shown, a reaction system for synthesizing silicon nitride powder includes a microwave plasma preheater, a suspension reactor and an insulation cooler connected in sequence.

[0081] The microwave plasma preheater includes a nitrogen pipeline 100 , a first injector 101 , a microwave plasma torch 102 (ceramic material), a second injector 103 , a preheater shell 104 and a coil 105 . The first injector is provided with a silicon powder addition port 106, the discharge end of the nitrogen pipeline extends into the first injector, the discharge end of the first injector is connected with the second injector, and the first injector The pressure inside is less than the pressure inside the second injector. The microwave plasma torch is arranged in the second injector; the coil is arranged in the shell of the preheater, and the discharge end of the second injector is connected with the feed end of the coil, and the shell of the preheater is connected with the...

Embodiment 2

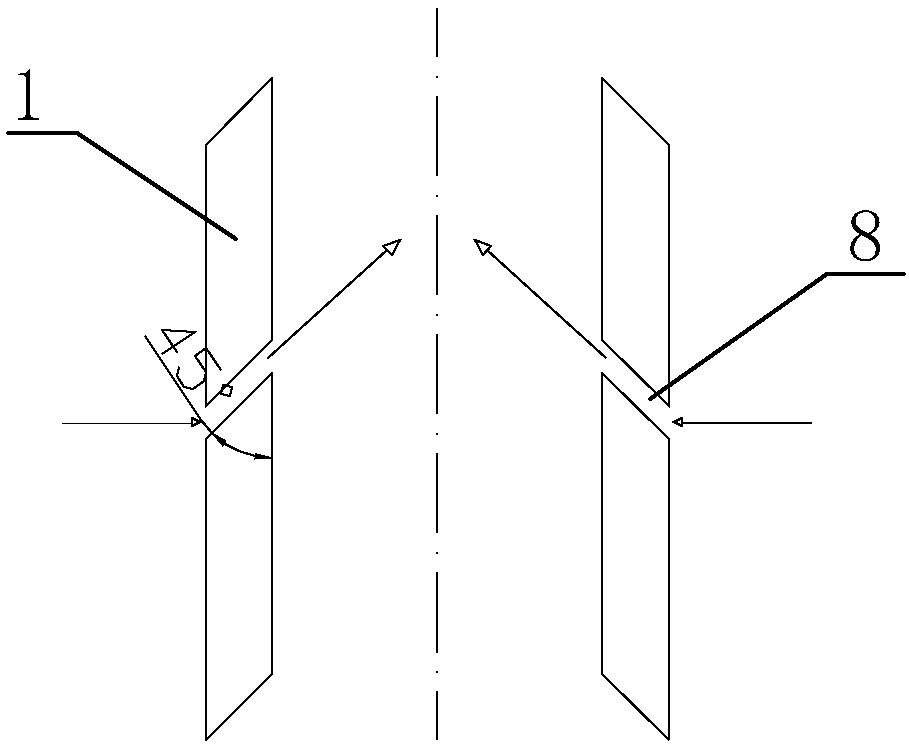

[0088] The difference between this embodiment and Embodiment 1 is that: the vertical angle of the air inlet slit is 30 degrees. And the air inlet slots are respectively provided with 1 layer and 5 layers in the heating area and the reaction area.

Embodiment 3

[0090] The difference between this embodiment and Embodiment 1 is that: the vertical angle of the air inlet slit is 50 degrees. And the air inlet slots are respectively provided with 1 layer and 3 layers in the heating zone and the reaction zone.

[0091] Reactor production of the present invention compares with main index in the industry

[0092] index

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com