Large-size ultrathin metal matrix density gradient material, and preparation method and application thereof

A density gradient, ultra-thin metal technology, applied in the field of powder metallurgy, can solve the problems of too thick single layer thickness and limited application fields, and achieve the effects of low cost, widening application scope and good pore uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

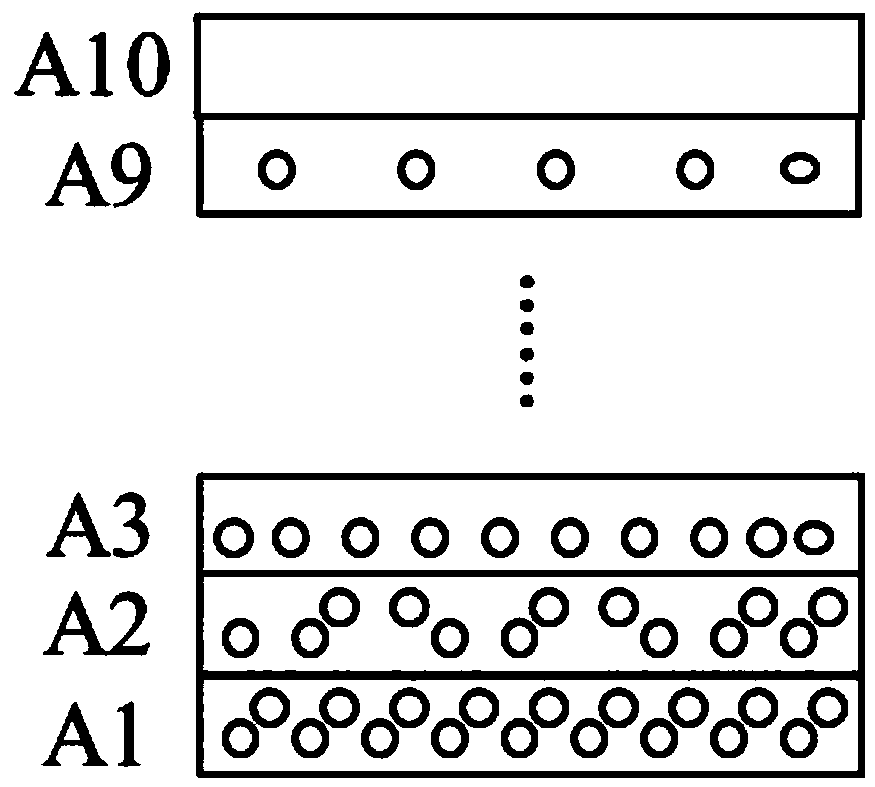

[0047] Step 1: Powder pretreatment and component preparation; dry the aluminum matrix powder (2A12 powder) with a particle size of 8-15 μm and the spherical sodium chloride powder with a particle size distribution of 30-50 μm in an oven at 80° C. for 4 hours. According to aluminum alloy powder: porogen powder = X: (100-X) mode is equipped with different systems of composite raw material powder; 2A12 powder and water-soluble pore-forming agent powder according to different volume fraction ratio (the value of X is respectively 60, 70 and 80), respectively numbered A1-A3, and then mixed in a three-dimensional mixer for 3 hours at a speed of 20r / min, and then taken out and sealed in a vacuum environment for later use.

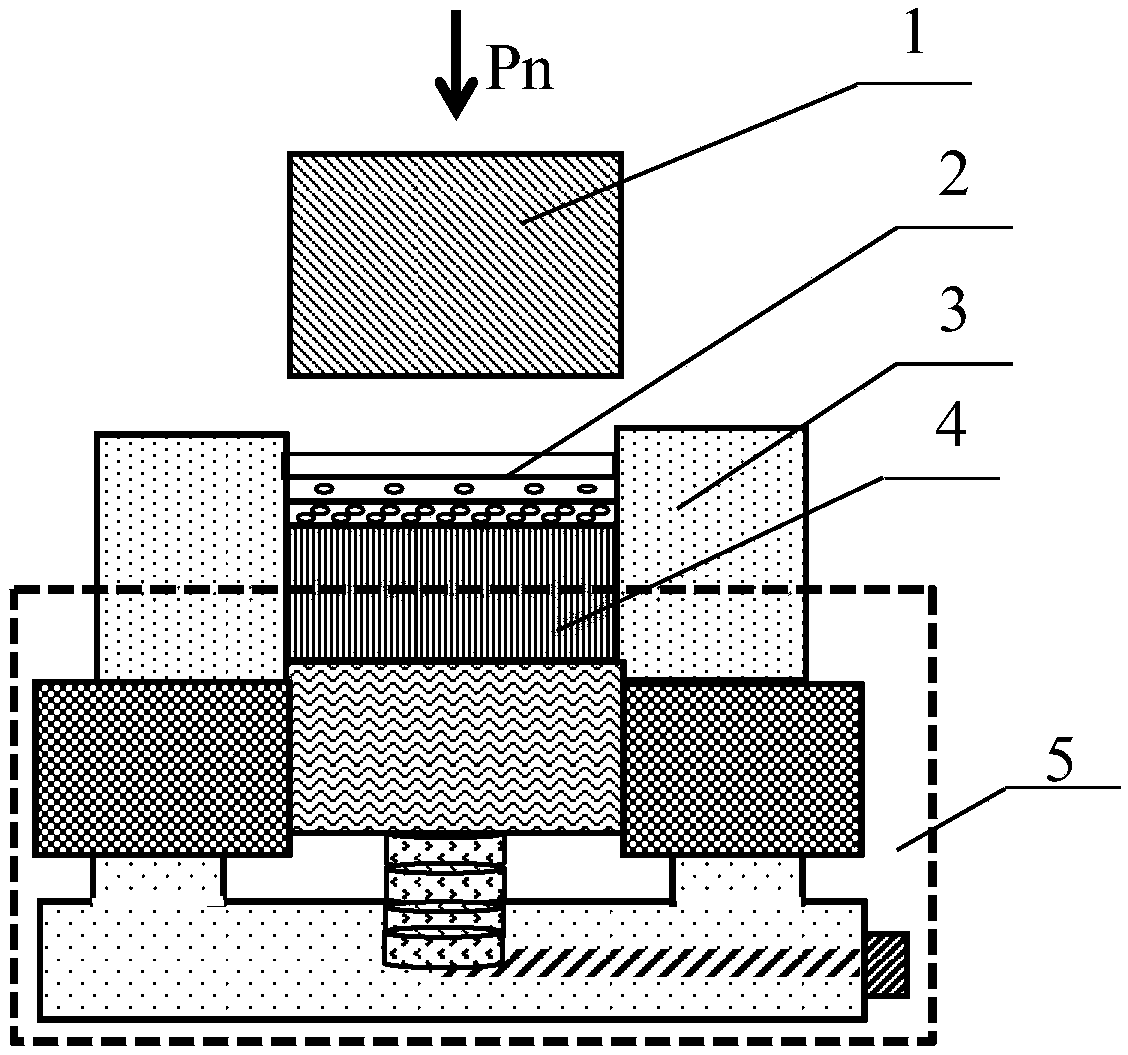

[0048] Step 2: Lay-up powder laying and forming; according to the design height, lower the screw height controller to a certain height, weigh A1 powder quantitatively, lay it flat in the cold press mold and pre-press at 300MPa, hold the pressure for 5s, and then put...

Embodiment 2

[0054] Step 1: Powder pretreatment and component preparation; drying the aluminum matrix powder with a particle size of 8-15 μm and the spherical sodium chloride powder with a particle size distribution of 30-50 μm in an oven at 80° C. for 4 hours. According to aluminum alloy powder: porogen powder = X: (100-X) mode is equipped with different systems of composite raw material powder; 2A12 powder and water-soluble pore-forming agent powder according to different volume fraction ratio (the value of X is respectively 60, 70, 80, 90 and 100), respectively numbered A1-A5, and then mixed in a three-dimensional mixer for 3 hours at a speed of 20r / min, and then taken out and sealed in a vacuum environment for later use.

[0055] Step 2: Lay-up powder forming; replace the φ100mm forming mold, lower the screw height controller to a certain height according to the design height, weigh the A1 powder quantitatively, lay it flat in the cold pressing mold, and carry out 300MPa pre-compression...

Embodiment 3

[0061] Step 1: Powder pretreatment and ingredient preparation; dry the aluminum matrix powder with a particle size of 8-15 μm and the floating bead powder with a particle size distribution of 55-70 μm in an oven at 80° C. for 4 hours. According to the aluminum alloy powder: porogen powder = X: (100-X) mode is equipped with composite raw material powder of different systems; 2A12 powder and floating beads are proportioned according to different volume fractions (the value of X is respectively 60, 70, 80, 90 and 100), respectively numbered A1-A5, and then mixed in a three-dimensional mixer for 3 hours at a speed of 20r / min, and then taken out and sealed in a vacuum environment for later use.

[0062] Step 2: Lay-up powder forming; replace the φ100mm forming mold, lower the screw height controller to a certain height according to the design height, weigh the A1 powder quantitatively, lay it flat in the cold pressing mold, and carry out 300MPa pre-compression and pressure-holding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com