Electron beam partition scanning forming method for porous tungsten material

A porous tungsten and electron beam technology, which is applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problem of inability to directly shape special-shaped porous materials, difficulty in controlling the distribution and depth of porous tungsten pores, and difficulty in ensuring pore connectivity, etc. Problems, to achieve the effect of improving strength and purity, low cost, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

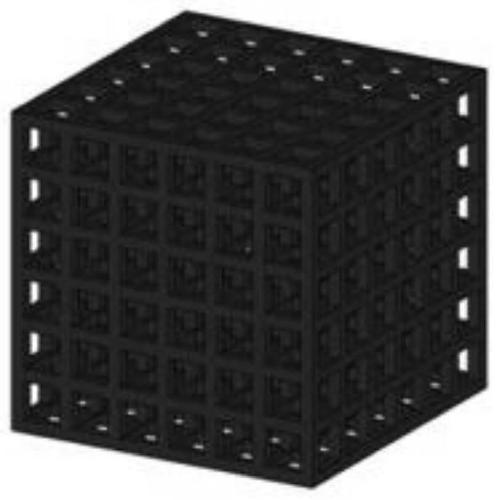

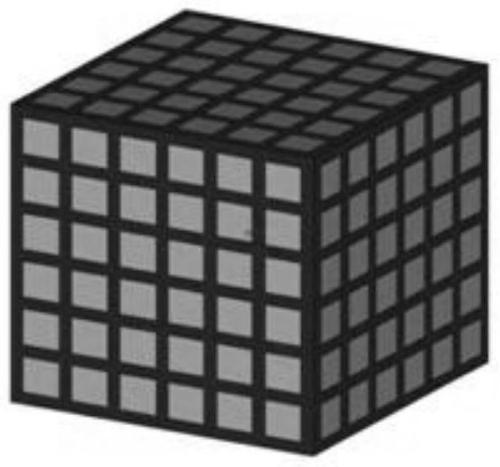

[0031]The porous tungsten material of this embodiment is composed of a three-dimensional lattice structure and a porous body filled in the pores of the three-dimensional lattice structure. The size of the porous tungsten material is 20mm × 20mm × 20mm, and the porosity is 30%. The electrons of the porous tungsten material The beam partition scanning shaping method includes the following steps:

[0032] Step 1, using three-dimensional modeling software to establish a three-dimensional lattice structure model; the size of the three-dimensional lattice structure model is 20mm * 20mm * 20mm, and the porosity is 90%;

[0033] Step 2, establishing a porous body model according to the internal pore area of the three-dimensional lattice structure model established in step 1;

[0034] Step 3. Merge the three-dimensional lattice structure model established in step 1 with the porous body model established in step 2 to obtain a porous tungsten material model, and then perform layered pr...

Embodiment 2

[0041] The porous tungsten material of this embodiment is composed of a three-dimensional lattice structure and a porous body filled in the pores of the three-dimensional lattice structure. The size of the porous tungsten material is 20mm × 20mm × 20mm, and the porosity is 22%. The beam partition scanning shaping method includes the following steps:

[0042] Step 1, using three-dimensional modeling software to establish a three-dimensional lattice structure model; the size of the three-dimensional lattice structure model is 20mm * 20mm * 20mm, and the porosity is 90%;

[0043] Step 2, establishing a porous body model according to the internal pore area of the three-dimensional lattice structure model established in step 1;

[0044] Step 3. Merge the three-dimensional lattice structure model established in step 1 with the porous body model established in step 2 to obtain a porous tungsten material model, and then perform layered processing along the height direction of the po...

Embodiment 3

[0050] The porous tungsten material of this embodiment is composed of a three-dimensional lattice structure and a porous body filled in the pores of the three-dimensional lattice structure. The size of the porous tungsten material is 20mm × 20mm × 20mm, and the porosity is 20%. The electrons of the porous tungsten material The beam partition scanning shaping method includes the following steps:

[0051] Step 1, using three-dimensional modeling software to establish a three-dimensional lattice structure model; the size of the three-dimensional lattice structure model is 20mm * 20mm * 20mm, and the porosity is 80%;

[0052] Step 2, establishing a porous body model according to the internal pore area of the three-dimensional lattice structure model established in step 1;

[0053] Step 3. Merge the three-dimensional lattice structure model established in step 1 with the porous body model established in step 2 to obtain a porous tungsten material model, and then perform layered p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com