Preparation method and application of polyethylenimine-modifed magnetic microspheres

A technology of polyethyleneimine and magnetic microspheres, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of low adsorption capacity and achieve good stability and reproducibility Good, simple and effective preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Fe 3 o 4 Preparation method of @PDA@PEI magnetic microspheres

[0028] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0029] 2.7g FeCl 3 ·6H 2 O and 7.2g of anhydrous sodium acetate were uniformly dispersed in 80mL of ethylene glycol under ultrasonic, and placed under room temperature under magnetic stirring for 3 hours to make it fully mixed; then, 3.0g of polyethylene glycol was added to the above-mentioned yellow solution; After stirring evenly, transfer them to a stainless steel reaction kettle and seal it; react at 200°C for 10 hours. After cooling to room temperature, the product was washed three times with absolute ethanol and ultrapure water, and then dried under vacuum at 50°C for 2 hours.

[0030] (2) PDA-coated Fe 3 o 4 Preparation of magnetic nanoparticles (Fe 3 o 4 @PDA)

[0031] 180mg Fe 3 o 4 Nanoparticles were ultrasonically dispersed in 80.0mL of Tris-HCl solution (10mM, pH 8.5), and then 10.0mL of Tris-HCl solution in whi...

Embodiment 2

[0034] Embodiment 2: Structural characterization of magnetic materials

[0035] (1) Particle size and morphology characterization

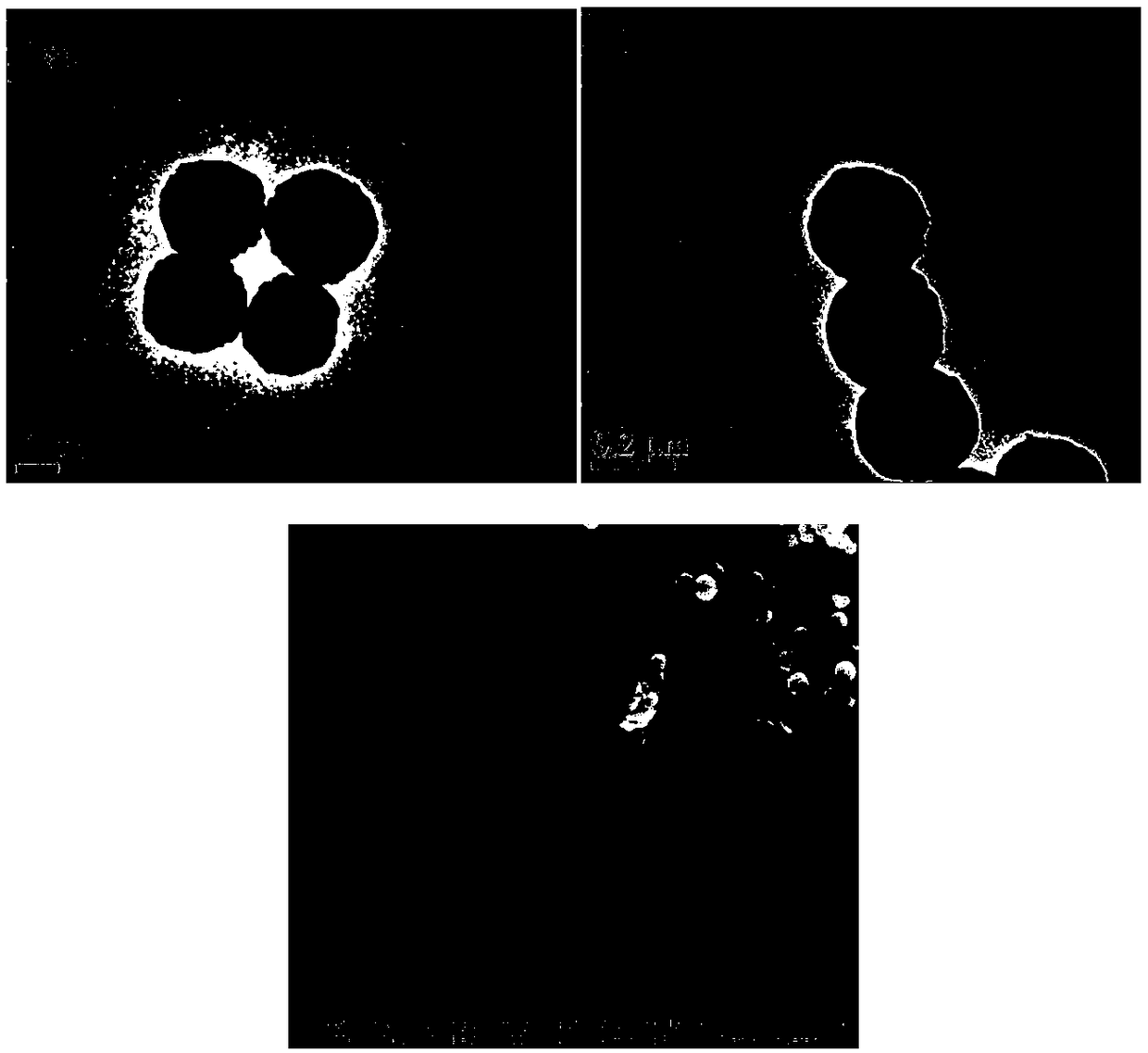

[0036] The particle size and morphology of the prepared magnetic microspheres were observed by JEM100CXII transmission electron microscope (JEOL Corporation) and NOVA NanoSEM 430 (US FEI Company) field emission scanning electron microscope. from figure 1 It can be seen that the synthesized bare Fe 3 o 4 Nanoparticles are regular spherical, uniform particle size, and good dispersion; Fe 3 o 4 @PDA nanoparticles have an obvious core-shell structure, and the thickness of the PDA layer on its surface is about 20nm. figure 1 (c) is Fe 3 o 4 The scanning electron microscope image of @PDA@PEI, this result further proves that the functionalized magnetic nanoparticles have a regular spherical structure, and the particle size is uniform; A more serious reunion between them.

[0037] (2) Element characterization

[0038] The X-ray energy loss spect...

Embodiment 3

[0045] Example 3: The magnetic microspheres of surface-modified polyethyleneimine are used to determine four kinds of pigments in food

[0046] Under optimized experimental conditions, four mixed pigment standard solutions of a series of concentrations were prepared for liquid chromatography separation (instrument model was 1260 high performance liquid chromatography (Agilent Technologies (China) Co., Ltd.); the chromatographic column was Venusil XBPC 18 Column (150×4.6mm i.d., 5μm), the column temperature was constant at 30°C; the mobile phase was 20mM ammonium acetate-methanol, the flow rate was 1mL / min, and the injection volume was 20μL), and the peak area of each analyte was compared with the concentration. Calibrate the curve, and use the least square method to perform linear regression at the same time, the results are shown in Table 1, the linear range of the four pigments is wide, and they have good correlation, and the correlation coefficient is greater than 0.999. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com