Method of constructing multi-functional biomimetic modified layer on surface of cardiovascular implant material based on vascular basement membrane structure

An implant material and cardiovascular technology, applied in coatings, pharmaceutical formulations, medical science, etc., can solve the problems of lack of endothelial cells, etc., and achieve the effect of easy-to-operate preparation process, significant effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

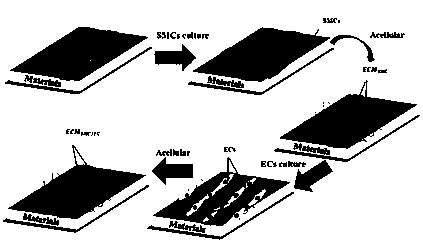

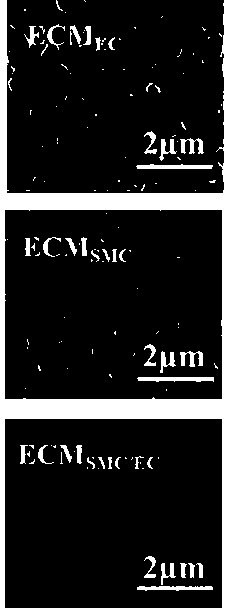

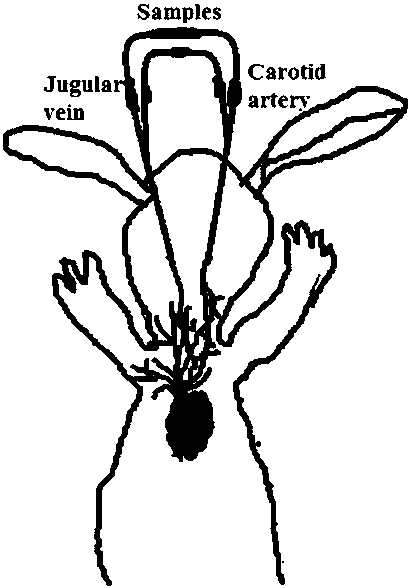

[0036] See figure 1 The first specific embodiment of the present invention is based on the structure of the vascular basement membrane, adopting the patterned dual cell culture-desorption mode to biomimize the construction of a multifunctional modified layer on the surface of stainless steel. The steps are:

[0037] A. Prepare a molecular weight of 5×10 on the polished stainless steel surface 5 DA hyaluronic acid (HA) stripe-like micropatterns, the stripe width of HA is 100nm, and the stripe width of bare material is 200nm, ready for use;

[0038] B. Preparation of patterned vascular smooth muscle extracellular matrix on the surface of stainless steel: the vascular smooth muscle cells passaged for 3 generations were divided into 5×10 4 The density of pieces / ml is planted on the surface of the micro-pattern described in step A, at 37℃, the volume percentage concentration is 5% CO 2 Cultivate for 3 days under the standard culture conditions of HA. In this step, the contractile smooth ...

Embodiment 2

[0042] Based on the structure of the vascular basement membrane, a patterned dual-cell culture-desorption mode is used to biomimically build a multifunctional modified layer on the titanium surface. The steps are as follows:

[0043] A. The molecular weight is 1×10 prepared on the polished titanium surface 6 DA's hyaluronic acid (HA) striped micro-patterns, the stripe width of HA is 25μm, and the stripe width of bare material is 25μm and 25μm respectively, ready for use;

[0044] B. Preparation of patterned vascular smooth muscle extracellular matrix on titanium surface: The vascular smooth muscle cells of 2 passages were divided into 1×10 5 The density of pieces / ml is planted on the surface of the micro-pattern described in step A, at 37℃, 5% CO 2 Cultivate for 2 days under standard culture conditions of concentration. This step obtains contractile smooth muscle cells with elongated shapes and orderly arrangement after being controlled by HA micropatterns; aspirate the used cell cu...

Embodiment 3

[0048] Based on the structure of the vascular basement membrane, a patterned dual cell culture-desorption mode is used to biomimize the construction of a multifunctional modified layer on the surface of the magnesium alloy. The steps are as follows:

[0049] A. The molecular weight is 4×10 prepared on the surface of magnesium alloy 3 DA's hyaluronic acid (HA) stripe-like micro-patterns, the stripe width of HA is 30μm, and the stripe width of bare material is 20μm respectively, ready to use;

[0050] B. Preparation of patterned vascular smooth muscle extracellular matrix on the surface of magnesium alloy: The vascular smooth muscle cells of the second passage were divided into 1×10 6 The density of pieces / ml is planted on the surface of the micro-pattern described in step A, at 37℃, the volume percentage concentration is 5% CO 2 Cultivate for 1 day under the standard culture conditions of HA. In this step, the contractile smooth muscle cells with elongated shape and orderly arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com